Pharmaceutical Intermediates and Specialty Catalysts: India’s chemical segment has an excellent potential. Worldwide customers are no longer interested in sole supplier agreements. Hence, there is an unevenly high demand for pharma acclimatisers and specialty catalysts. These are acclimatisers that decrease. Obviously, there is an increase in green chemistry. For Indian start ups, these galas are export driven, with high margins and long life.

Market Potential-Pharma Intermediates & Specialty Catalysts

Pharma exports from India surpassed $25 billion in 2024. Nevertheless, the country still remains an importer of a large chunk of its pharma intermediate products. The catalysts market is available in several parts of the world and is worth several billions with an annual growth rate of 6 – 7%. North America and Europe are the most active parts. Customers from these regions tend to be more careful and are interested in quality and sustainable systems. It is a low hanging fruit which Indian companies can exploit more easily to develop a reliable business in importing cheap pharma intermediates and next gen catalysts.

Read Our Book: Click Here

Main Demand Stimulators-Pharma Intermediates & Specialty Catalysts

Expansion of the Healthcare Sector is the most important and includes the augment of API consumption. Reshoring and regulatory strictness boosts the market’s growth of secondary suppliers. Green chemistry and ESG focus interest shifts towards bio-catalysts and systems with lower energy demand. Indian policy instruments such as the PLI for the pharma and specialty catalysts and the stimulation of startups with greater public funding for R&D enable rapid near market expansion.

Read More: Simplifying Equipment Setup and Maintenance: How Visual Guides Help New Manufacturers

An Overview of the Production of These Goods-Pharma Intermediates & Specialty Catalysts

Pharmaceutical Intermediates implement multi-step organic syntheses and reactions like halogenation, hydrogenation, nitration and esterification. All operations work under GMP and are subjected to strict impurity controls. For specialty catalysis, the supports are alumina, silica or zeolite, and the active metals are Pd, Pt, Ni, or Co. These are produced from the methods impregnation, precipitation, sol-gel synthesis and calcination. Outstanding units are known due to their implementation of continuous flow systems, automation and inline analytics that safeguard reproducibility(Pharma Intermediates & Specialty Catalysts).

Read More: How to Start Recycling Business of PET Bottle – Recycling Business Ideas

Promising Prospects for New Companies

- API Intermediates: Target the niche and complex molecules for oncology, anti-virals, and anti-infectives as these are more expensive in comparison.

- Green Catalysts: Bio and enzyme catalysis for niche fine chemicals and pharmaceuticals are for ESG interested buyers.

- Custom Catalysts: Targeted reactions in refinery and pharma entail custom choosing and tailoring catalysts for hydrogenation, polymerization, etc. There is good potential for profit and IP(-Pharma Intermediates & Specialty Catalysts).

- Catalyst Recovery and Regeneration: There is business model potential in recovering precious metals and other catalysts to increase margins and recovering catalysts to extend their lifetimes.

- Agrochemical Crossovers: There is potential in pharma and agrochemicals to capture markets with the integration of diversified revenue streams with intermediates and catalysts.

Read Our Project Report: Click Here

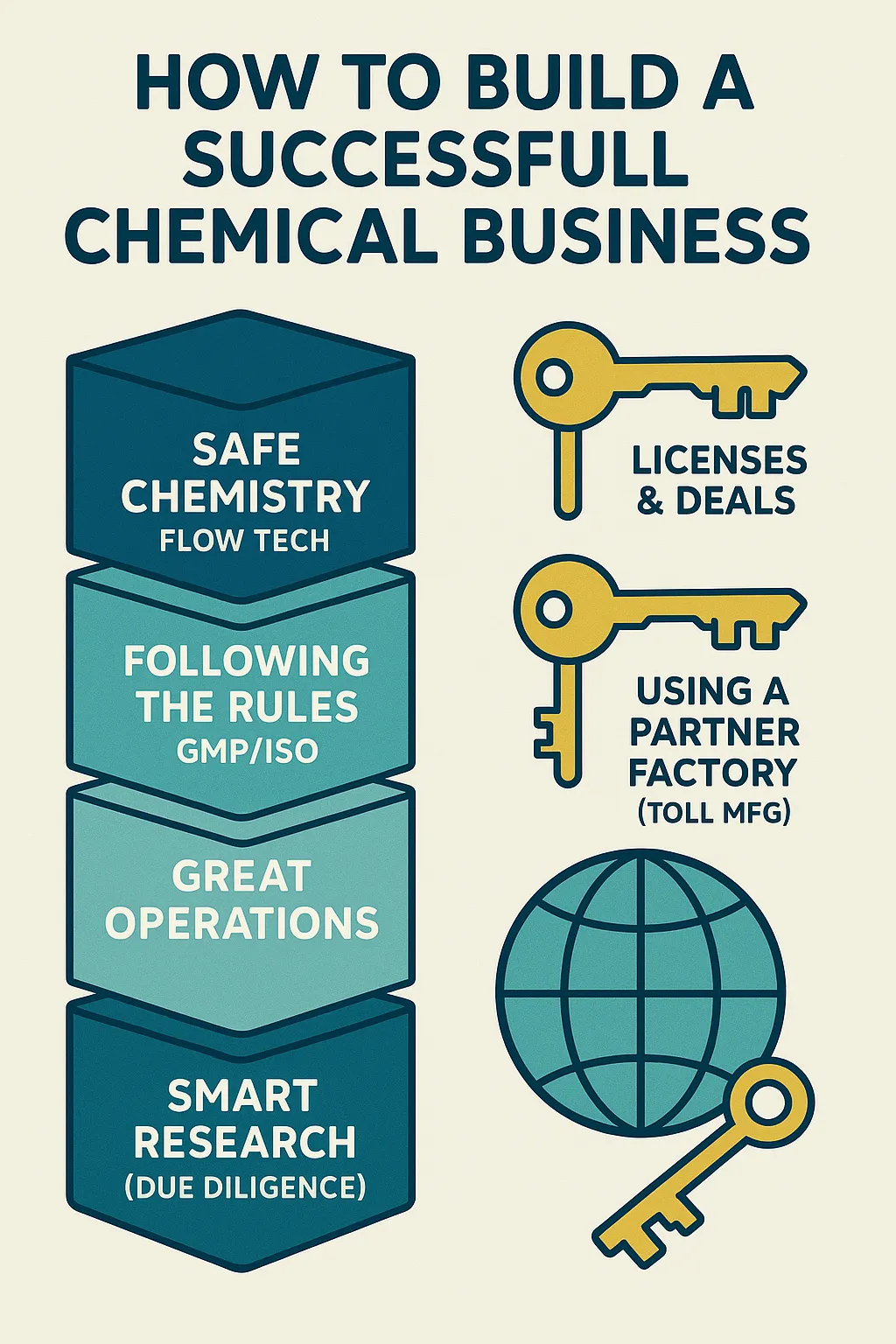

Tech and Regulatory Specifications

To have a successful business, you need to perform thorough due diligence, have operational excellence, and good regulatory compliance. Flow chemistry is a way to enhance safety for processes that involve hazardous and/or sensitive steps. Certain quality control systems (GMP, ISO, environmental clearances) are mandatory for international markets. Legal access to research pacts and licenses, along with toll manufacturing, provide the most efficient means to market access(Pharma Intermediates & Specialty Catalysts).

Effective Business Models-Pharma Intermediates & Specialty Catalysts

- Contract Manufacturing: Develop partnerships with global CMO pharma and manufacture the pharma intermediates.

- Product & Service: Offering catalysts and a subscription model for regeneration and recycling for catalysts.

- Export First: intermediate customers are from Africa, Latin America, and South and Southeast Asia while ensuring compliance to strict regulatory and technical requirements for EU/US catalysts.

- Niche IP Plays: Create independently, develop fully, and own proprietary processes, catalysts, and then license to big companies.

Read More: Chemical Exports in 2025: Opportunities for Indian Startups

Financing and Policy Related Opportunities

Incentive programs released by governments, for example, PLI for specialty chemicals and the PLI programs also lowers the cost of capital. ESG blended financing is provided for the green catalysts projects. A good DPR is critical to attracting the right investors and structuring bank loans.

Find the Best Idea for Yourself With our Startup Selector Tool

What NPCS Does For Purpose Entrepreneurs

NPCs help and guide you with expertise to produce the techno-economic feasibility report (DPR). This includes detailed market surveys. The report includes manufacturing processes, control systems, machinery, and finances. From that DPR, NPCS helps the startups get the required funding and the right partners.

Justifying The Act-Pharma Intermediates & Specialty Catalysts

The increasing healthcare demands, the green chemistry paradigm shifts, and globally diversifying supply chain are giving a great, breathable runway year after year. Integrated chemistry, compliance, and export are what make Indian Start Ups great. With NPCs, focused R&D and market access, catalyst and intermediates units can achieve great growth and sustained profitability.

Frequently Asked Questions-Pharma Intermediates & Specialty Catalysts

1. What Are Pharma Intermediates?

A. Pharma Intermediates Are Like The Building Blocks Of A Kids Construction Set. These Are The Different Chemicals That Are Used To Construct An API (Active Pharma Ingredients).

2. Why Are Specialty Catalysts More Important?

A. Because They Speed Up Reactions, Increase The Yields, Reduce The Energy Requirements, And Facilitate The Greening Of The Chemical Processes.

3. What Is The Expected Investment An Entry Level Startup Is Required To Have In This Space?

A. The Capital Requirements Are Widely Dispersed In The Pharma Chemistry Units. The Smaller And Medium Intermediate Plants Have Higher Capex In The Reactors, Utilities And Effluent Treatment. Catalyst Units Demand Specific And More Expensive Equipment As Well As More R&D.

4. What Are Possible Starting Points In Which A Startup Can Lessens The Market Entry Risk?

A. These Are Contract Manufacturing, Collaborative Research And Flow And Financed Technologies To Acquire A DPR(Pharma Intermediates & Specialty Catalysts).

5. In What Manner Does NPCS Assist Chemical Startups?

A. NPCS Carries Out Detailed Market Research, Examines The Local Processing And Compliance Processes, And Then Creates The Entire Legal Framework For The Project To Ensure That It Is Financed(Pharma Intermediates & Specialty Catalysts).