The modern construction has been revolutionized with lightweight structure, thermal insulation, resistance to fire, and economical cost of Autoclaved Aerated Concrete (AAC) blocks. With the increasing rate of urbanization and the need to use sustainable construction, more people are choosing AAC blocks than conventional clay bricks and concrete blocks.

This paper gives a clear and detailed description of the AAC Blocks manufacturing process including raw materials, plant layout, batching, casting, cutting, autoclaving, quality inspection, and packaging. It also delves into the technical, the working process and the key quality measures that make it to come out successful. At the conclusion, the readers will be in a position to have a comprehensive idea on the AAC blocks production process, the reasons why it is becoming popular and the factors to be considered when setting up a production unit.

Introduction

Precast lightweight foam concrete building materials are called AAC blocks and are used in the construction of homes and commercial buildings. They are characterized by low density, high strength-weight ratio and high insulation. Rapid infrastructure development and requirement of eco-friendly construction materials has seen the demand of AAC blocks rise dramatically.

AAC blocks manufacturing process in India entails the blending of fine aggregates, cement, lime, gypsum, water and little bit of aluminum powder. This mix enlarges as a result of a chemical reaction, creating air bubbles in the concrete mix. Once the initial setting is done, the material is cut into blocks and cured at high pressure steam autoclaves, which increase both strength and durability.

Knowledge on the methodology of production is essential to the entrepreneur, engineers and investors willing to set up a manufacturing plant . It involves careful management of the raw materials, temperature, pressure and the time needed to cure in order to maintain quality of the products.

Read Project Details: AAC BLOCKS (AUTOCLAVED AERATED CONCRETE BLOCKS) FLY ASH BASED – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study

What Are AAC Blocks?

AAC blocks are light weight pre cast concrete blocks that have been produced using natural raw materials. They are full of millions of small air pores created as a result of the chemical interaction of aluminum powder and lime. These air spaces ensure that the blocks are lighter compared to the normal bricks and still possess structural integrity.

AAC blocks are mostly used in non-load bearing and load bearing walls. Their thermal resistant feature lowers the use of energy in buildings. They are also good soundproofs and good fire resistant materials. Due to their standard size and their smooth finish, they save on mortar consumption and construction time.

Composition of AAC Blocks

The fly ash or sand, cement, lime, gypsum, water, and aluminum powder are the main constituents of AAC blocks. Fly ash is an additive filler and enhances sustainability through recycling of industrial wastes. Silica reacts with Lime to form calcium silicate hydrates, which is the source of strength.

Aluminum powder is important in that it forms hydrogen gas during the reaction process. This gas creates micro air cells in the mixture. After the process is completed and the curing process is initiated, the gas is expelled leaving the strongest and yet porous structure.

Key Properties of AAC Blocks

AAC blocks are very light, as they are usually one-third the weight of the normal clay bricks. They have adequate compressive strength applicable in most structural applications. They are very thermal resistant, and their heating and cooling is minimized in structures.

Along with insulation, AAC blocks have great fire resistance, usually lasting up to four hours depending on the thickness. They are also very suitable in residential and commercial buildings because of their sound insulation qualities.

Raw Materials Required for AAC Blocks Manufacturing

AAC blocks require raw materials that are of high quality. Every component serves a certain purpose in the chemical reaction and ultimate block performance.

The base material is made up of fly ash or silica sand. Cement is a unifying agent. Calcium required in the reaction is supplied by lime. Gypsum controls the time of setting and the aluminum powder provides the aeration effect.

Fly Ash or Silica Sand

The constraint of fly ash is that it is abundant and has a positive impact on the environment; therefore, it is widely found in the production of AAC. It enhances workability and adds to strength. Where the fly ash is not available, one may use silica sand.

Mixing must be consistent and proper grinding and control of particle size is necessary. Chemical composition should be of certain standards to be able to react best with lime.

Aluminum Powder and Additives

Small amounts of aluminum powder are added to cause aeration. It combines with the calcium hydroxide present in the slurry to give off hydrogen gas. The gas creates small air bubbles which expand the mixture.

Other additions can consist of expansion agents or accelerators to regulate the timing of reactions. Pore distribution should be uniform and this is achieved by careful dosage.

Step-by-Step AAC Blocks Manufacturing Process

AAC Blocks manufacturing process has various processes that need accuracy and technical regulation. All the stages are vital towards achieving block strength, uniformity and durability.

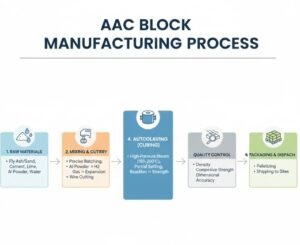

Preparation of the raw materials starts followed by mixing and batches. The mixture is then poured into molds and left to expand and then cut into blocks. Lastly, the blocks are cured in high pressure autoclaves.

Mixing and Slurry Preparation

Raw materials are quantified based on a set formula. Fly ash or sand is combined with water to slurry. The mixture is then added to cement, lime and gypsum.

Aluminum powder is added after mixing thoroughly. That is its immediate reaction, resulting in hydrogen bubbles, which make the slurry expand.

Casting, Cutting, and Autoclaving

During the casting, cutting, and autoclaving process, the nucleus is produced, and the denture is created, respectively.

The carbonated mixture is used in molds and left to ferment. After being partially set, it is excised and sliced into blocks with high precision wire cutting machines.

The green blocks are passed onto autoclaves where high pressure steam is used to cure them. This enhances the strength of the material because the material becomes crystallized in calcium silicate hydrate, which improves the durability and structural performance of the material.

How Does Autoclaving Strengthen AAC Blocks?

The process of Autoclaving is high pressure steam curing that considerably increases the physical properties of AAC blocks. It entails exposure of the cut blocks to steam at a temperature of about 180 200 centigrade and pressure of 8-12 bar.

This increases the rate of chemical reactions between silica and lime to give stable crystalline structures. This leads to enhanced compressive strength and dimensional stability.

Chemical Reaction in Autoclave

Silica is reacted with calcium hydroxide under high pressure to produce tobermorite crystals. These crystals also offer structural power and inflexibility.

The regulated surrounding gives the block a consistent cure. This gets rid of stresses within the structure and minimizes cracking.

Benefits of Autoclave Curing

Autoclaving saves more time than the conventional process. It increases the lifecycle, thus AAC blocks are resistant to the environment and moisture damage.

The process also guarantees the quality consistency and this is critical to high volume production and commercial applications.

Machinery and Equipment Used in AAC Plants

Manufacturing process of AAC Blocks need special equipments in order to have an efficient production. This is because automation is important in ensuring uniformity and minimizing labor expenses.

Among the important equipment are ball mills, slurry tanks, mixers, molds, cutting machines, autoclaves, as well as packaging systems.

Mixing and Casting Equipment

The raw materials are ground to the required fineness in ball mills. Slurry tanks are used to store and control the consistency of mixtures. Mixers are used, but at high speeds to create homogenous mixture.

Casting molds are also made so as to expand uniformly. They largely come with automatic pouring systems.

Cutting and Autoclaving Units

Wire cutting machines give the machine the correct block dimensions. Accuracy is enhanced through automation, as well as waste.

Autoclaves are high pressure vessels that can withstand high temperatures and pressure of steam. The design is such that they are safe and uniformly cured.

Quality Control Measures in AAC Manufacturing

Quality control is very important so that blocks can be up to construction standards. The batches are tested on density, compressive and moisture content.

Consistency of raw materials is ensured by their frequent inspection. Chemical composition and particle size is tested through laboratory testing.

Physical Testing

The Compressive strength tests ascertain load bearing capacity. Lightweight property is guaranteed with the use of density tests.

Dimensional accuracy is inspected to give unproblematic installation and little mortar application.

Process Monitoring

Automatic systems are used to control temperature, pressure and mixing ratios. Any deviation is rectified at the time.

The monitoring as a continuous activity enhances productivity and minimizes manufacturing mistakes.

Search latest business plans

Is AAC Block Manufacturing Profitable in India?

The blocks of manufacturing process in India has been growing tremendously because of the increasing construction demand and government efforts that promote the use of sustainable materials. Profitability of an AAC plant is based on location, availability of raw materials, plant capacity and demand.

The rising construction of infrastructure and suburban housing programs drives the need to adopt lightweight materials in building. AAC blocks bring about economies of transportation and labour making them competitive in the market.

Market Demand and Growth

AAC is increased with the help of urbanization and smart city efforts. The constructors choose AAC due to speed and energy saving.

Developing more environmental awareness only adds to the demand of eco-friendly materials.

Investment and Returns

Preliminary investment comprises machinery, land, utilities and working capital. Dividends are based on output and volume of sales.

Profitability and reputation in the market are boosted with the help of efficient management and quality assurance.

Environmental Impact of AAC Blocks Production

However, the production of AAC is environmentally friendly than the normal brick kilns. It utilizes industrial wastes like fly ash and also consumes less energy in the production process.

The low weight helps cut down the transportation fuel. Thermal insulation conserves the energy consumed by buildings.

Sustainable Resource Utilization

Recycling fly ash decreases the waste in a landfill. Manufactured production reduces emissions.

Systems of water recycling minimize the use of water in industries.

Energy Efficiency Benefits

ACA blocks used in constructions consume less heating and cooling in buildings. This reduces the total carbon footprint.

Green building is in line with sustainable production.

Check this Book for various business plans

AAC Block Manufacturing Project Report Overview

AAC Block Manufacturing Project Report is a report which will give technical, financial, and operation analysis to set up a plant. It involves market research, planning of the plant capacity, sourcing of raw materials, and financial estimates.

The report describes machinery requirements, cost estimation and break even analysis. It assists investors to determine the viability of the project and risk.

Technical Feasibility

Includes plant layout, equipment specifications and utility requirements. It achieves adherence to environmental and safety standards.

Financial Planning

Capital investment estimates, operational expenses and revenue forecasts are included. Proper estimates are used to justify finances and loans.

Read Our Project Report

FAQ

What are AAC blocks made of?

The blocks of AAC are produced using fly ash or sand, cement, lime, gypsum, water and aluminum powder. These materials are chemically reactive to create a light weight porous structure of concrete.

What is the duration of AAC bi-block curing?

Autoclave curing is commonly conducted at high pressure and is normally 812 hrs. This guarantees maximum strength and durability.

Are AAC more powerful compared to clay bricks?

The AAC blocks have adequate compressive strength to be used in most building projects but they are much lighter than clay bricks.

Is manufacturing of AAC blocks environmentally friendly?

Yes, it is made of recycled resources such as fly ash and less power is used to make it as compared to the conventional brick-making.

How long does AAC blocks last?

AAC blocks are very strong and may last decades in sound installations and maintenance.