The developing interest in the Circular Economy and Eco-friendly practices gives more attention to recycling used tyres. Producing Crumb Rubber Powder from Waste Tyres is probably the best and most profitable recycling option. This process involves shredding tires into finer rubber granules or powders that can be used for road construction, rubberized asphalt, athletic and gym floor tracks, flooring, moulded rubber products, and even new tires.

It appears this guide will be most useful to investors and entrepreneurs planning to establish additional projects in the recycling industry. This step-by-step guide will take you through the production of crumb rubber from analyzing market needs to procuring machinery, raw materials, and finances. This article draws from the experiences captured by NPCS, the project consultancy service arguably the most detailed project report provider and market survey agency in India.

1. Definition of Crumb Rubber Powder and Its Applications

What is Crumb Rubber Powder?

Crumb rubber is a type of industrial rubber produced from used tyres. The powder can vary in particle size, from coarse granules (~10 mm) to fine powder (<1 mm). It maintains the elastic and durable properties of natural rubber, which enables its use in many industries.

Common Applications

- Rubberized roads and asphalt

- Rubber mats and tiles

- Sports and playground surfaces

- Automobiles (Bumpers, Pads, etc.)

- Roofing Products

- Footwear and Other Molded Articles

- Waterproofing Modified Bitumen

2. Market Potential of Crumb Rubber Powder from Waste Tyre

Global Scenario

Recent research puts the Global tyre recycling market at $9.65 Billion by 2030, growing at a CAGR of 5.2%. Crumb rubber forms a large share of this market due to its wide applicability and growing need towards infrastructural development.

Indian Scenario

With over 275,000 tonnes of waste tyres generated annually, India is…

Here is CPWD approved bitumen rubberized projects for the sub national and state level PMGSY, NHAI, and smart city missions which has a high need for crumb rubber powder.

Important Factors

- Increasing concern for the environment

- Prohibitive policy on landfilling and incineration of tyres

- Widespread usage in the construction of roads

- Government initiatives in support of recycling and green manufacturing

Related: Manufacturing Business of Rubber Granules from Waste Tyre

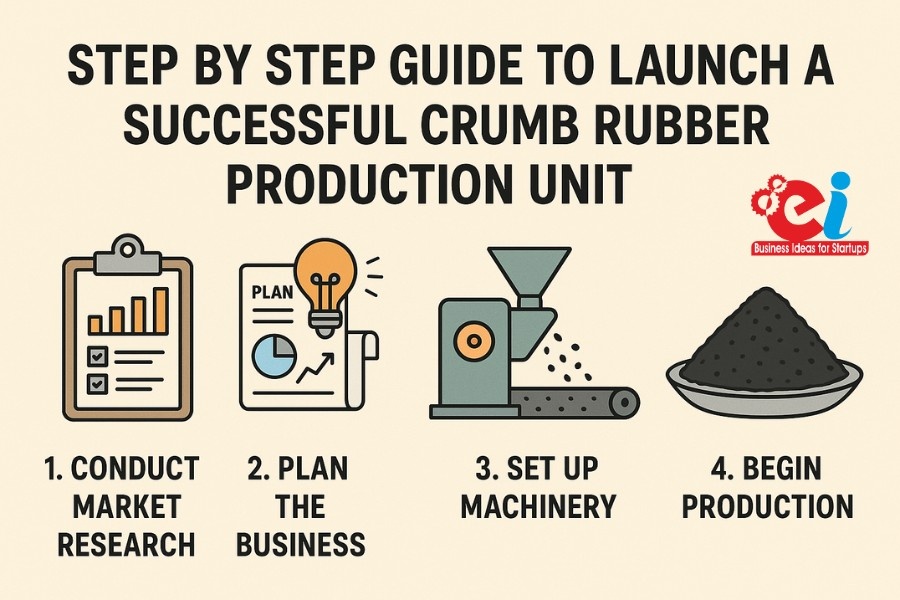

3. Instructions on How to Start a Crumb Rubber Production Facility

Step 1: Prepare for Market Feasibility Research

Inquiring requires a soft Techno-Economic Feasibility Report (TEFR) on a few preliminary aspects such as:

- Demand for the area

- Observing competition

- Accessibility of raw materials

- Break-even point analysis

- Return in Investment versus time and period

NIIR Project Consultancy Services (NPCS) offers tailored customized feasibility reports that contain complete dossier and market insights along with financial projections.

Step 2: Choose The Most Suitable Place

Consider the following when selecting the place:

- Quartering to sources of materials (scrap tyres)

- Availability of power, water, and other industrial services and resources

- Efficiency in transportation and logistics

- Compliance with state boundary pollution and zoning regulations

Preferred regions in India:

- Industrial clusters in Maharashtra, Tamil Nadu, Rajasthan, and Gujarat

- Proximity to vehicle scrap yards and tyre landfills

Step 3: Compliance and Obtaining the Necessary Legal Documents

Proceed to apply for the following business licenses and registrations:

- Business Registration (MSME/Startup India)

- Consent for setting up and operating from SPCB

- Factory registration

- Tax Identification Number (GST)

- Pollution Abatement Certificate

- Environmental Impact Study (EIA) if needed

Step 4: Purchase Equipment and Machinery

Here are the principal pieces of equipment for a 5 TPD plant:

| Unit | Expected Price Range (INR) |

| Tyre Cutter | ₹8–10 Lakhs |

| Steel Wire Remover | ₹6–7 Lakhs |

| Bead Remover | ₹4–5 Lakhs |

| Crusher (Primary & Secondary) | ₹15–20 Lakhs |

| Granulator/Grinder | ₹12–18 Lakhs |

| Magnetic Separator | ₹3–4 Lakhs |

| Vibratory Screening Machine | ₹4–5 Lakhs |

| Dust Collection System | ₹2–3 Lakhs |

| Control Panel and Conveyor Belts | ₹6–8 Lakhs |

NPCS provides the suppliers of the machinery as well as the layout, utility, and cost estimation for DPRS.

Step 5: Infrastructure Development

Create the following further infrastructures:

- Shed or factory building (minimum of 3000–4000 sq. ft.)

- Electricity connection (approx. 100–150 kVA)

- Water tank along with a borewell (where applicable)

- Ventilation and fire protection systems

- Administrative office and welfare facilities for employees

Step 6: Raw Material Procurement

Major Raw Materials:

- Discarded or Worn Out Tyres

- Waste Nylon/Radial Tyres

- Rubber waste and conveyor belts (if available)

🛻 Partnerships:

- Local tyre retailers

- Municipal scrapyards

- Car tyre retreading firms

- Freight and transport firms

Step 7: Production Process Flow

Crumb Rubber Powder Production Process:

- Cutting Tyre: Splitting larger tyres into three to four pieces.

- Bead Wire Removal: Removing steel wires with the help of a bead wire remover.

- Shredding: Primary and secondary shredders cut the tyres into chips measuring 50–100 mm.

- Granulation: The chips are further reduced to pieces between 5–10 mm.

- Magnetic Separation: All metal wiring is extracted through magnets.

- Milling/Grinding: The granules are reduced to granular powder (30–120 mesh).

- Screening: Vibrating screens ensure the powder is graded uniformly.

- Packing: The final product is packaged in HDPE bags weighing 25/50 kg for resale.

Manpower Need as it is:

| Personnel | Quantity |

| Plant Manager | 1 |

| Machine Operators | 3–4 |

| Helpers | 4–5 |

| Electrician/Technician | 1 |

| Supervisor/Admin | 1 |

| Security & Housekeeping | 2 |

Training is required on the machinery operations, safety instructions, and quality control.

Marketing Plan Focus on:

- Asphalt contractors

- Asphalt mix plant operators

- Sports surface companies

- Manufacturers verre rubbere

- Exporters in the Middle East, Africa, and Europe

Channels:

- B2B Trade Sites such as: IndiaMART and TradeIndia

- Industry trade fairs and expos

- Target cold contacting and OEM Partnerships

- LinkedIn and digitally

.

5. Challenges & Risk Mitigation

Challenges and Risks:

- Inconsistent scrap tyre supply

- High-Energy Consumption

- Diminishing Industry Demand

- Competition from unorganized players

Risk Mitigation Strategies:

- Investment in infrastructure and equipment will be secured by long-term contracts for the supply of CNC machined components.

- Contractual agreements with contractors for energy-efficient machines.

- Involves programs for correcting rubber compounds used.

- Participating in government schemes (PMEGP, EPR Compliance) helps mitigate other program related risks.

6. Government Support & Subsidies

- MSME Subsidy Schemes

- Credit Linked Capital Subsidy Scheme (CLCSS)

- Support for the Recycling Industry through EPR (Extended Producer Responsibility)

- Recognition from Startup India

- PMEGP Subsidies up to ₹25 Lakhs

Identifying qualifying subsidy schemes and registering startups is also the job of NIIR Project Consultancy Services.

7. How NPCS Can Help You Succeed

Providing Stand-alone Rubber Powder Production, NPCS tailor makes project proposal documents, including:

- Tailored Project Reports

- Comprehensive Industry Research

- Business Plan with flowing projections

- Equipment Vendor List

- Legal Filing Checklist

- Layout & Structural Drawings

- Loan and Grant Application Support

Headquartered in New Delhi, NPCS is experienced in setting up 2 TPD to 10 TPD plants, and has executed projects in tyre recycling, rubber processing, and green industry manufacturing.

Visit entrepreneurindia for more information on starting a crumb rubber business and contact us for assistance.

Conclusion

Establishing a Crumb Rubber Powder from Waste Tyre unit will reap benefits and conserve the environment starting from 2025. India is expected to make progress in the field of rubber production, especially due to the growing focus on sustainability, infrastructure development, waste management and boosting the economy.

Entrepreneurs can confidently tackle the helps of technical, financial, and regulatory difficulties, especially when aided by experienced consultants like NPCS. Following this guide will make the endeavor simpler.

Don’t let this change of opportunity to roll out waste. Invest in a cleaner planet and profitable future today by starting your crumb rubber production journey!