India is undergoing a massive industrial transformation. Across major states such as Gujarat, Maharashtra, Tamil Nadu, and Odisha, large-scale capacity expansions, new manufacturing zones, and advanced industrial corridors are shaping the next decade of economic growth. According to data from the Ministry of Heavy Industries, production of engineering goods, capital equipment, automobiles, electrical machinery, metals, castings, forgings, and fabrication products is rising rapidly — directly boosting the growth of industrial clusters in India. For new entrepreneurs, this creates one of the most promising business eras in decades. As industrial regions expand, they open dozens of opportunities for MSMEs — from component manufacturing and fabrication to logistics, machining, maintenance services, and industrial consumables. This detailed guide breaks down the fastest-growing industrial clusters in India and the best MSME-friendly manufacturing ideas you can start around them.

Read Our Project Report: Click Here

1. Why Industrial Clusters in India Are Critical for New Entrepreneurs

Industrial clusters reduce costs, strengthen supply chains, and create predictable demand for thousands of MSMEs in engineering and manufacturing.

1.1 They Attract Massive Industrial Investments

High-growth clusters attract:

- Automotive giants

- Engineering and fabrication companies

- Heavy machinery manufacturers

- Steel and aluminium producers

- EV ecosystem players

These large players form a strong ecosystem where MSMEs can thrive.

1.2 They Create Stable Supplier Demand

Cluster-centric manufacturing requires:

- Fasteners

- Fabrication components

- Castings & forgings

- CNC machined parts

- Electrical components

- Packaging materials

- Industrial consumables

This ensures consistent, recurring orders for MSMEs.

1.3 They Boost Export Readiness

Many industrial clusters in India are located near major ports, increasing export potential.

- Gujarat – Kandla, Mundra

- Maharashtra – JNPT

- Tamil Nadu – Chennai, Ennore

- Odisha – Paradip, Dhamra

This makes clusters ideal for export-focused MSMEs.

2. Major Industrial Clusters in India & Business Ideas You Can Build Around Them

Below are India’s most powerful emerging clusters, their strengths, and the MSME opportunities they create.

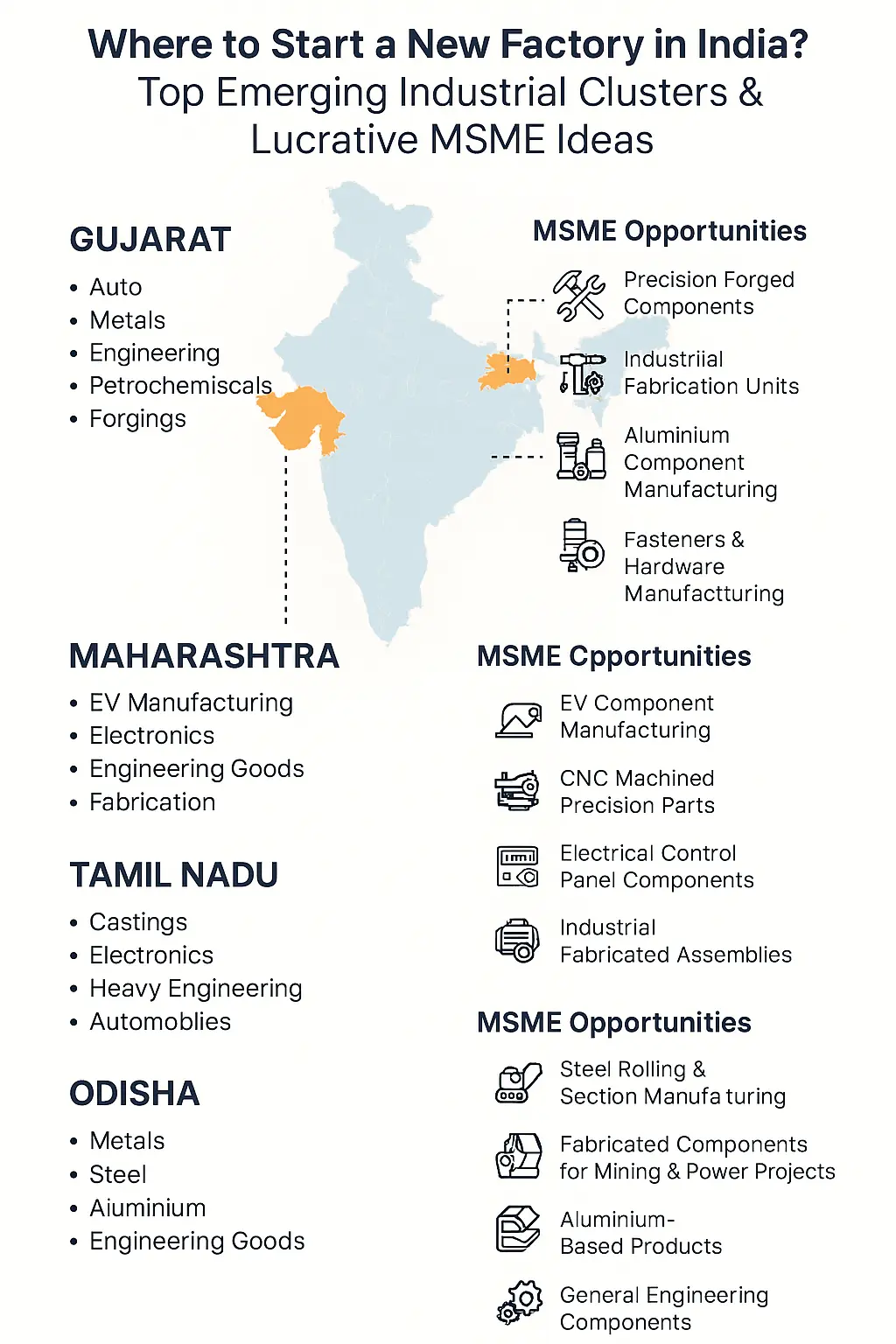

2.1 Gujarat — Auto, Metals, Engineering, Petrochemicals, Forgings

Gujarat is one of the strongest industrial clusters in India, known for its dominance in heavy engineering, auto components, metalworking, and fabrication. The state is witnessing rapid growth in:

- Engineering goods manufacturing

- Metal casting & forging units

- Automobile production and vendor parks

- Steel rolling & fabrication clusters

- High-volume export-focused ports

2.1.1 High-Potential Business Ideas for Gujarat

A. Precision Forged Components

Demand is driven by automotive and engineering sectors for:

- Axles

- Shafts

- Gears

- Bearing races

- Agricultural machinery parts

B. Industrial Fabrication Units

High demand for:

- Steel structures

- Pipe racks

- Conveyor systems

- Warehouse racking

- Rolling mill parts

C. Aluminium Component Manufacturing

Driven by the growth of EV and electrical machinery:

- Motor housings

- Battery casings

- Heat sinks

- Die-cast housings

D. Fasteners & Hardware Manufacturing

Growing engineering and construction activities make fastener production extremely profitable.

Read More: Business, Industrial Directory, Database, List of Companies, Small & Medium Enterprises

2.2 Maharashtra — EV Manufacturing, Electronics, Engineering Goods

Maharashtra is emerging as a major cluster for:

- Electric vehicle manufacturing

- Machine tools

- Heavy engineering

- Fabrication units

- Industrial machinery

2.2.1 MSME Business Ideas for Maharashtra

A. EV Component Manufacturing

- Aluminium die-cast parts

- Battery enclosures

- Motor housings

- Power electronics casings

B. CNC Machined Precision Parts

- Shafts

- Couplings

- Pins and bushes

- Fixtures

C. Electrical Control Panel Components

- MCC & PCC enclosures

- Switchgear frames

- Relay housings

- Copper/Aluminium busbars

D. Industrial Fabricated Assemblies

- Sheet metal cabinets

- Structural frames

- Conveyor assemblies

- Machinery guards

2.3 Tamil Nadu — Automotive, Heavy Engineering, Castings, Electronics

Tamil Nadu is one of India’s most industrially advanced regions, dominating:

- Auto manufacturing

- Foundries & castings

- Electronics

- Renewable energy equipment

- Machine tools

2.3.1 MSME Business Ideas for Tamil Nadu

A. Cast Iron & SG Iron Components

- Pump bodies

- Valve castings

- Brake drums

- Transmission parts

- Motor housings

B. Sheet Metal Auto Components

- Seat frames

- Body brackets

- Instrument panel supports

- EV chassis parts

C. Industrial Motors & Engineering Assemblies

- Motor casings

- Stator & rotor stampings

- Fabricated motor frames

D. Aluminium Die-Cast Products

- HVAC housings

- Auto body parts

- Electronic enclosures

2.4 Odisha — Metals, Steel, Aluminium, Engineering Goods

Odisha is emerging as an eastern manufacturing powerhouse in the list of leading industrial clusters in India. The state excels in:

- Steel production

- Aluminium smelting

- Mining machinery

- Fabrication & engineering goods

- Metals manufacturing

2.4.1 MSME Ideas for Odisha’s Industrial Growth

A. Steel Rolling & Section Manufacturing

- Angles

- Channels

- TMT

- Structural steel products

B. Fabricated Components for Mining & Power

- Conveyor parts

- Bucket structures

- Hoppers

- Wear plates

- Plant structures

C. Aluminium-Based Products

- Die-cast aluminium parts

- Extruded components

- Heat sinks

- Electrical fittings

D. General Engineering Components

- Shafts

- Gears

- Spindles

- Bushes

These cases illustrate how early visualization, innovation and scale can lead to global success. Read Our Book: Click Here

How NPCS Supports Entrepreneurs in Building These Projects

At Niir Project Consultancy Services (NPCS), we prepare professional Market Survey–cum–Detailed Techno-Economic Feasibility Reports (DPRs) for setting up new industries or businesses. Our reports include:

- Detailed manufacturing processes

- Market demand analysis

- Process flow diagrams

- Product mix & capacity planning

- Machinery and raw material details

- Financial projections & profitability analysis

We help entrepreneurs identify the right location, right product, and right investment size for maximum ROI — especially inside fast-growing industrial clusters in India.

3. Import–Export Logic: Why MSMEs Benefit

3.1 Import Substitution Opportunities

India still imports:

- Specialty castings

- Precision forgings

- Automotive electronic housings

- Industrial fasteners

MSMEs in Gujarat, Maharashtra, Tamil Nadu, and Odisha can easily replace these imports.

3.2 Export Potential

Engineering MSMEs in major clusters export heavily to:

- UAE

- Africa

- Southeast Asia

- LATAM

Highly exportable products include:

- Fabrication assemblies

- CNC parts

- Aluminium machined components

- Sheet metal auto parts

4. Success Stories of Indian Industrial Tycoons

4.1 Ratan Tata — Industrial Pioneer

Drove India’s growth in steel, engineering, and automobiles — proving how clusters evolve into global hubs.

4.2 Sajjan Jindal — Steel Visionary

Built world-class steel and alloy capacities, supporting downstream MSMEs.

4.3 Baba Kalyani — Forging Industry Legend

Showcased India’s capability in world-leading engineering and forging technologies.

4.4 Anand Mahindra — Mobility & Auto Growth Champion

Created strong vendor ecosystems across multiple states, enabling thousands of MSMEs to thrive.

Find the Best Idea for Yourself With our Startup Selector Tool

5. Conclusion: Industrial Clusters in India Are the Future of Manufacturing

The booming industrial clusters in India across Gujarat, Maharashtra, Tamil Nadu, and Odisha offer unprecedented opportunities for entrepreneurs. With rising demand for engineering goods, auto components, metals, fabrication, and industrial equipment — 2025 is the best time to start a manufacturing business. Entrepreneurs benefit through:

Guaranteed India is undergoing a massive industrial transformation. Across major states such as Gujarat, Maharashtra, Tamil Nadu, and Odisha, large-scale capacity expansions, new manufacturing zones, and advanced industrial corridors are shaping the next decade of economic growth.According to data from the Ministry of Heavy Industries, production of engineering goods, capital equipment, automobiles, electrical machinery, metals, castings, forgings, and fabrication products is rising rapidly — directly boosting the growth of industrial clusters in India.For new entrepreneurs, this creates one of the most promising business eras in decades. As industrial regions expand, they open dozens of opportunities for MSMEs — from component manufacturing and fabrication to logistics, machining, maintenance services, and industrial consumables.This detailed guide breaks down the fastest-growing industrial clusters in India and the best MSME-friendly manufacturing ideas you can start around them.

6. FAQs About Industrial Clusters in India

Q1. Which state is best for starting a metals-based manufacturing unit?

Gujarat and Odisha are considered the best states for metals-based manufacturing. Gujarat has a strong steel and alloy ecosystem, while Odisha is known for large-scale aluminium and steel production supported by major industrial corridors and port access.

Q2. Which industrial cluster is ideal for fabrication units?

Tamil Nadu, Maharashtra, and Gujarat offer the most favorable conditions for fabrication businesses. These regions host major engineering companies, auto manufacturers, machine tool producers, and large industrial projects that consistently require fabrication components.

Q3. What low-investment manufacturing businesses can be started near industrial clusters?

Some of the best low-cost MSME business ideas include fasteners, sheet metal parts, CNC machined components, aluminium components, and fabrication job-work units. These products have steady demand across all major industrial clusters in India.

Q4. Do these industrial clusters support export-oriented units?

Yes, most major clusters—especially in Gujarat, Maharashtra, Tamil Nadu, and Odisha—are located near international ports such as Mundra, JNPT, Chennai Port, and Paradip. This makes it easy for MSMEs to supply to global markets and tap into high-margin export opportunities.

Q5. How does NPCS support entrepreneurs planning to start units in these clusters?

NPCS assists entrepreneurs by preparing Detailed Project Reports (DPRs), market research studies, cost and profitability analysis, machinery selection guidance, and complete techno-economic feasibility assessments. These reports help entrepreneurs choose the right product, right capacity, and right industrial location for maximum ROI.