MSME Metal Fabrication Business: India’s industrial landscape is undergoing one of its strongest expansions in recent decades. The year 2024–25 marks a decisive shift in the country’s capabilities across steel, aluminium, engineering goods, fabrication, castings, forgings, and heavy machinery manufacturing.

Multiple industries — power generation, transmission, automotive, railways, defence, infrastructure, and capital goods — are expanding capacity, commissioning new projects, and sourcing higher volumes of engineered components. This growth has created a powerful opportunity wave for MSMEs in the metals, fabrication, and forging sectors.

Industrial giants are reporting record order books, engineering companies are executing high-value fabrication works across the country, and foundry-forge units are scaling output for power, machine tools, and transportation sectors. For startups and new entrepreneurs, this environment is ideal for entering metal-based manufacturing businesses that require moderate investment but deliver high and stable demand.

This article breaks down profitable MSME manufacturing opportunities, inspired by India’s rising industrial capacity, new project announcements, and domestic supply chain needs — all structured for SEO visibility, startup relevance, and business practicality.

Read Our Project Report: Click Here

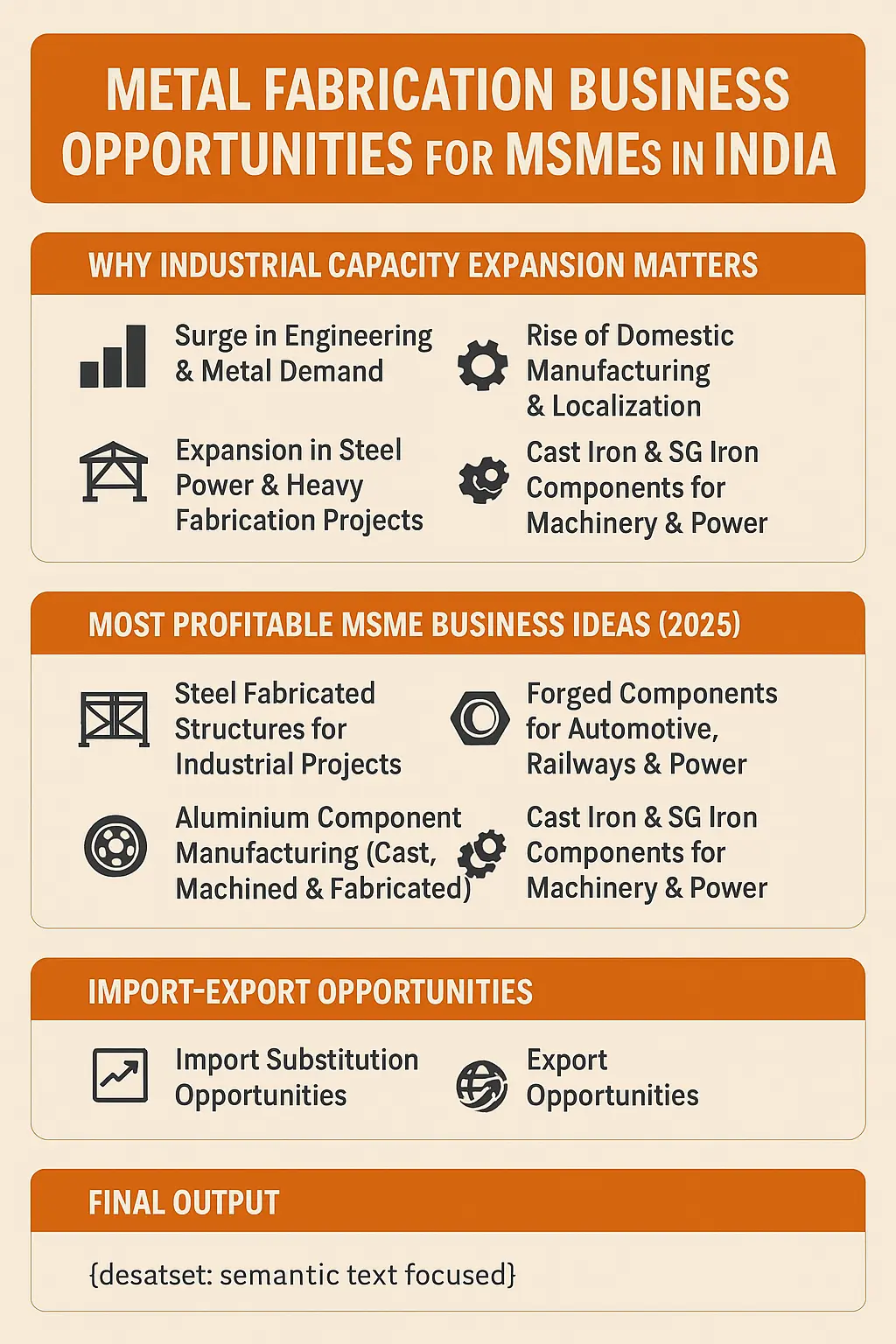

1. Why Industrial Capacity Expansion Matters for MSME Metal Fabrication Business

1.1 Surge in Engineering & Metal Demand

India’s engineering and capital goods ecosystem has expanded significantly across:

- Steel structures

- Heavy machinery

- Power plant equipment

- Fabricated components

- Castings & forgings

- Aluminium and non-ferrous components

Multiple public sector enterprises have recorded strong capacity utilization, major fabrication contracts, and increased project commissioning. This steady pipeline of industrial contracts drives enormous demand for metal-based components that MSMEs are well-positioned to supply.

1.2 Rise of Domestic Manufacturing & Localization

Across railways, power, automobiles, and heavy engineering, there is a strong push for:

-

- Local sourcing

- MSME participation

- Vendor development programs

- Reduction of imported metal components

These trends create direct openings for new small and medium manufacturing units.

1.3 Expansion in Steel, Power & Heavy Fabrication Projects

Engineering companies are involved in:

- Transmission tower fabrication

- Boiler drums

- Pressure vessels

- Steel structures for bridges, industrial plants, and port infrastructure

- Railway bridge girders

- Mining machinery components

This provides a multi-year market for fabricated metal products sourced from MSMEs.

Read Our Book: Click Here

2. Most Profitable MSME Business Ideas in Metals, Forgings & Fabrication (2025)

Each of the following business ideas is written with a startup-friendly approach: moderate investment, high market demand, and long-term viability.

2.1 Steel Fabricated Structures for Industrial Projects

India’s ongoing projects across power, fertilizer, petrochemical, steel, and infrastructure sectors require massive quantities of fabricated structures.

High-demand items MSMEs can manufacture:

- Industrial sheds and platforms

- Transmission line tower parts

- Pre-engineered building components

- Conveyor galleries

- Steel bridges and small girders

- Stairs, pipe racks, catwalks, handrails

Why this is a strong opportunity

- Fabrication workshops can be set up with moderate investment

- High demand from EPC contractors

- Stable orders from industrial zones

- Fastest-growing MSME-friendly engineering segment

Fabrication businesses benefit from India’s expanding construction, port, highway, and industrial plant development.

2.2 Forged Components for Automotive, Railways & Power

Forging is one of India’s most powerful MSME sectors, but demand has surged due to growth in:

- Railways

- Commercial vehicle production

- Power plant component manufacturing

- Oil & gas equipment

Products an MSME can manufacture

- Forged shafts

- Crankshafts

- Railway track components

- Gear blanks

- Connecting rods

- Flanges

- Heavy-duty rings

Why forging is profitable

- High durability and reliability required by OEMs

- India has strong metallurgy know-how

- Lower competition in precision forging

- Excellent export potential

Forgings are integral to railways, power plants, defense machinery, and transportation equipment.

2.3 Aluminium Component Manufacturing (Cast, Machined & Fabricated)

The move towards lightweight engineering systems — especially in automobiles, EVs, and power equipment — has led to a huge increase in aluminium component demand.

Product ideas

- Aluminium cast housings

- Electrical enclosure parts

- EV battery housings

- Motor covers

- Heat sinks & cooling fins

- High-pressure die-cast components

- Aluminium fabricated brackets

Why aluminium is a high-growth category

- Lightweight metals preferred across engineering

- Strong shift from steel to aluminium in automotive

- High export demand for fabricated aluminium parts

MSMEs can start with small furnaces, die-casting machines, and machining centers.

2.4 Cast Iron & SG Iron Components for Machinery & Power

Medium and heavy castings play a vital role in India’s power, mining, engineering, and machine tool sectors. Several manufacturing units supply:

- Boiler components

- Turbine housings

- Pump bodies

- Mining equipment castings

- Machine tool beds

Products suitable for MSMEs

- Gear housings

- Brake drums

- Pump impellers

- Bearing housings

- CI brackets and plates

Why castings are ideal for new entrepreneurs

- Abundant domestic scrap

- Strong orders from engineering PSUs and private OEMs

- High-volume demand

- Predictable growth due to industrial expansion

Even a small or mid-sized foundry can supply components to multiple sectors.

2.5 Precision CNC Machined Components

India’s industrial modernization has created strong demand for high-precision machined parts. MSMEs can supply:

- Shafts

- Nuts & bushes

- Couplings

- Flanges

- Pins & spacers

- Precision machined rings

- Automotive brackets

Why CNC machining works well for MSMEs

- Lower capex compared to large fabrication or foundry units

- High margins

- Quality-driven repeat orders

- Strong export potential

Machined components serve railways, power plants, EVs, and machine tool industries.

2.6 Transmission Tower Parts & Substation Hardware

With major upgrades in transmission infrastructure, demand has increased for:

- Cross arms

- Clamps

- Shackles

- Connectors

- Earthing materials

- Structural fittings

Why this is a promising MSME idea

- Required in every new transmission line project

- Long-term demand due to renewable energy expansion

- Standardized products simplify manufacturing

MSMEs can supply tower parts directly to EPC companies.

2.7 Pressure Vessels, Tanks & Process Equipment Fabrication

Engineering companies involved in petrochemicals, fertilizers, power, and steel require:

- Storage tanks

- Receivers

- Reactors

- Pressure vessels

- Heat exchanger shells

Why this idea stands out

- High-value, low-competition segment

- MSMEs can specialize in small-to-medium vessels

- Orders available from both public and private sector projects

Fabrication requires skilled manpower but offers strong returns.

2.8 Metal Furniture, Racking & Warehouse Fabrication

With the rise in e-commerce, logistics parks, and industrial warehouses, demand is growing for:

- Heavy-duty pallet racks

- Steel shelving systems

- Warehouse platforms

- Metal workstations

Why MSMEs should consider this

- Simple machinery needed

- Very high market demand

- Excellent margins

- Scalable business model

This segment continues to grow with India’s warehousing boom.

2.9 Railway Component Fabrication

Railways increasingly use fabricated metal components such as:

- Coach brackets

- Underframe components

- Sheet metal parts

- Fabricated assemblies

- Bogie structure parts

Why this is attractive

- Railways are expanding manufacturing facilities

- Strong vendor development programs for MSMEs

- Large recurring orders

Read More: The Complete Book on Ferrous, Non-Ferrous Metals with Casting and Forging Technology

3. Import–Export Opportunities for MSMEs in Metals & Fabrication

3.1 Import substitution opportunities

India still imports:

- Alloy cast components

- Special steel forgings

- EV aluminium housings

- Heat-resistant castings

- Large fabricated assemblies

MSMEs can fill these gaps by adopting modern machining, metallurgical, and fabrication technologies.

3.2 Export opportunities

Indian MSMEs have strong markets in:

- Middle East

- Africa

- Southeast Asia

- Latin America

Popular export categories include:

- Fabricated steel structures

- Forgings

- CNC components

- Aluminium fabricated items

- Cast iron parts

Export margins are higher due to value-added engineering.

4. NPCS Support for MSMEs in Metals, Forgings & Fabrication

At the center of this opportunity wave are entrepreneurs who understand feasibility, investment planning, and process optimization. This is where Niir Project Consultancy Services (NPCS) provides critical support.

We at Niir Project Consultancy Services (NPCS) provide professional consulting for the preparation of Market Survey cum Detailed Techno-Economic Feasibility Reports (DPRs) for setting up new industries or businesses.

Our reports include:

- Detailed manufacturing process

- Market research and demand analysis

- Process flow diagrams

- Product mix and capacity planning

- Machinery and raw material details

- Full project financials and profitability analysis

Our aim is to support entrepreneurs in evaluating the feasibility, profitability, and scalability of industrial projects.

NPCS acts as a guide to new industrial startups — helping them reduce risk, build clarity, and design profitable, bankable manufacturing ventures.

External References:

MNRE – Ministry of New and Renewable Energy

5. Success Stories of Indian Tycoons in Metals & Engineering

5.1 Sajjan Jindal (JSW Group)

A leader who scaled India’s steel capacity and transformed the metal supply chain through modernization and strategic acquisitions. His journey teaches MSMEs the value of technology and consistent quality.

5.2 Baba Kalyani (Bharat Forge)

Built one of the world’s largest forging companies. His success showcases India’s capability to manufacture high-precision components for power, automotive, and aerospace sectors.

5.3 Ratan Tata (Tata Group)

Known for strengthening India’s engineering backbone. From steel expansion to complex automotive fabrication, Tata’s legacy inspires innovation with purpose.

5.4 Anand Mahindra (Mahindra Group)

Scaled automotive, metal, and machinery sectors. His focus on local sourcing and domestic manufacturing uplifted the entire MSME ecosystem.

6. Conclusion

India’s industrial capacity expansion in 2024–25 is creating one of the most fertile environments for MSMEs in:

- Metals

- Fabrication

- Forgings

- Aluminium components

- CNC machining

- Engineering assemblies

The demand pipeline from power, engineering, railways, automobiles, machine tools, and infrastructure ensures high-volume orders for years to come.

For entrepreneurs who want to start manufacturing with long-term stability and strong profitability, now is the right time to step into metal-based MSME sectors.

7. FAQs

Q1. Which metal manufacturing business is best for MSMEs?

Steel fabrication, aluminium components, and forged parts are among the highest-demand categories.

Q2. What is the average investment required?

Small fabrication units can start with modest investment, while forging and casting require more capital.

Q3. Which sector will drive metal demand the most?

Power, railways, EVs, oil & gas, and infrastructure projects will drive the most demand.

Q4. Do these products have export potential?

Yes. CNC parts, fabricated structures, castings, and forgings have strong export demand in emerging markets.

Q5. How can NPCS help MSMEs get started?

NPCS provides feasibility reports, process guidance, machinery planning, financial projections, and technical insights to launch a profitable manufacturing unit.

Which business to start? How to choose a business idea?