It is an important undertaking to set up a food processing manufacturing facility for food processing. This requires careful planning, strategic implementation, and a thorough understanding of the complexities in this industry. Every step is important for success, from securing the best location and equipment to navigating through regulatory hurdles and setting up efficient processes.

This article is a comprehensive guide to setting up a food processing manufacturing unit. It covers key processes and essential considerations to help entrepreneurs thrive in this dynamic industry.

Market Analysis and Opportunity Assessment

A thorough market study is necessary before establishing your food processing manufacturing unit to validate your business concept and identify potential opportunities. Understanding the market dynamics and niches is essential to establishing a strong foundation.

Finding a niche market

Pinpoint a profitable niche by:

- Analyzing Consumer trends: Determine the growing demand for certain food types such as organic, plant based or convenience foods.

- Assessing market gaps: Determine unmet requirements in your local or region’s market, for example, ethnic foods or specialized diet items.

- Evaluation of Competition: Understand the strengths and weaknesses of competitors, which will reveal differentiation opportunities.

- Determining product viability: Determine the profitability and feasibility of specific products using demand, cost, and pricing.

Assessment of Market Demand

Get a better understanding of the market by:

- Focus groups and surveys: Get feedback from customers on their preferences, unmet need, and willingness-to-pay.

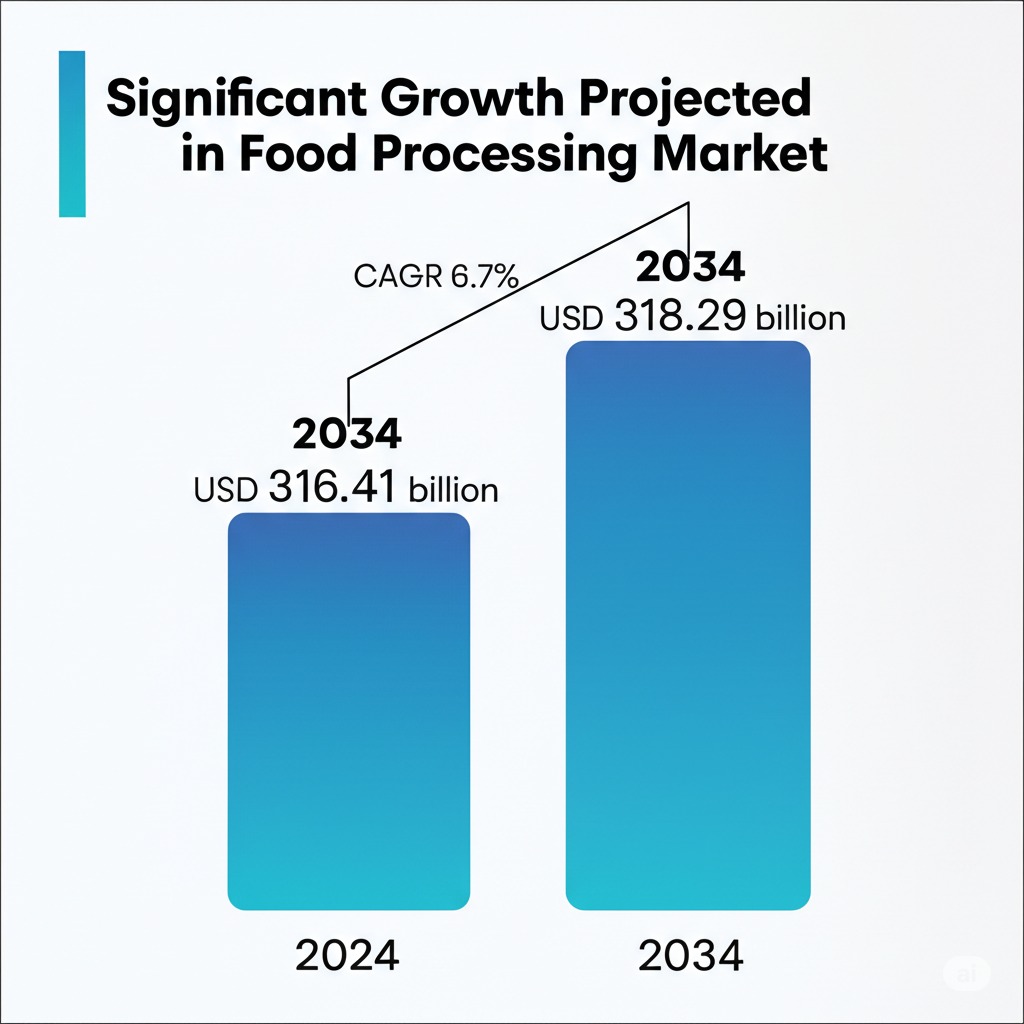

- Analysing Market Data: Use industry reports and statistics as a guide to determine the market size, potential growth, and trends.

- Evaluation of Distribution Channels – Identify the most effective distribution channels, such as supermarkets, restaurants or online retailers. Also, consider logistics and associated costs.

Related: How to Start a Profitable Food Processing Business

How to Develop a Comprehensive Business Plan

A well-structured plan of business is essential for a successful food processing manufacturing unit. This plan is a road map for your business. It outlines your goals, your strategies and your financial projections. It will guide you in your decisions and help you to secure funding from lenders or investors.

The Key Components in a Business Plan

- Executive Summary: Describe your business mission and goals in a few sentences. This should be an overview that is concise and captures the essence your business.

- Give detailed information on your company, including ownership, structure and history. This section should also include your company’s values and vision.

- Market Analysis: Include your findings, such as the target market, competitors, and market trends, from market research. This section should show a comprehensive understanding of the landscape.

- Product and Service: Highlight the unique features and advantages of your food products. Include information about your product, packaging, and ingredients.

- Plan your manufacturing process, including equipment needs and quality assurance measures. This section should show how you plan to efficiently and safely manufacture your product.

- Marketing and Sales strategy: Describe your plans to promote and sell your products. Include pricing, distribution and advertising. This plan should include all the steps necessary to reach your market.

The Right Location

The location of your food processing manufacturing unit is crucial for cost-effectiveness and regulatory compliance. Location can have a significant impact on your supply chain, your labor costs and your access to markets.

Important considerations for location selection

It is important to be close to the raw materials in order for transportation costs to be minimized and supply constant. Locating near farms or agricultural centres can be an advantage if you are processing fresh produce. Transport is also important. Access to major transport routes such as highways and railways will facilitate the efficient distribution of finished products. Your distribution costs will decrease the closer you are to important transportation hubs.

The availability of utilities is an important consideration. Verify that essential utilities such as water and electricity are available at reasonable prices. Water and energy are often required for food processing, so make sure that these resources are available. It is important to carefully consider zoning regulations.

Designing the Manufacturing Facility

Designing your facility for food processing manufacturing should ensure that it is efficient, safe, and compliant with all regulatory requirements. A well-designed manufacturing facility will improve efficiency and minimize contamination risks.

For more detailed information, view our Handbooks on Food Processing, Food Industry, Agriculture, Agro Processing

Key Design Principles

A smooth workflow is essential. Lay out the facility to reduce the amount of material and personnel moving around, streamlining the production process and reducing bottlenecks. Take into account the flow of materials, from receipt to processing to packing to storage to shipping. Food safety is dependent on hygienic design. Include hygienic principles in your design to help prevent contamination and make cleaning easier, like smooth surfaces, rounded edges, and proper drainage.

Many food products require temperature control. Install temperature control systems in order to maintain optimal conditions when storing, packaging, or processing food products. These systems may include heating, cooling, and refrigeration. Ventilation, air quality and other factors are often ignored. Air filtration and ventilation are essential to maintain a healthy and clean environment.

Lighting is important to improve visibility, safety and product quality. Proper lighting is also a way to improve employee morale. The design should include waste management. Design a waste-management system that is compliant with environmental regulations. This includes proper storage, separation, and disposal.

Employee facilities are also essential. To promote employee productivity and well-being, provide comfortable and hygienic facilities for employees, including restrooms, locker rooms, and break rooms.

Purchase of Equipment and Machinery

The right machinery and equipment is essential for high-quality and efficient food processing. Your equipment choice will have a direct impact on your production capacity, quality of product, and operating cost.

Key Equipment Categories

- Raw Material Handling Equipment includes conveyors, storage tanks, and elevators for receiving, storing and transferring raw material. They should be designed in a way that minimizes damage and contamination.

- Processing Equipment: This includes mixers and blenders as well as cookers, ovens or fryers. Equipment selection will be determined by the products that you are manufacturing.

- Packaging Equipment: This includes filling machines and sealing machines as well as labeling machines and cartoners to package food in different formats. Packaging automation can improve efficiency.

- Quality Control Equipment includes testing equipment, inspection system, and sensors to monitor product safety and quality. This equipment is crucial for ensuring that regulations are followed.

- Cleaning and Sanitation equipment: This includes cleaning systems, sanitizing units, and sterilization devices for maintaining a clean environment. Sanitation is essential for preventing foodborne illness.

Selecting Equipment

The key factors to consider are capacity and throughput. Select equipment that has enough capacity to meet production targets and also accommodate future growth. To avoid bottlenecks, it’s best to slightly overestimate your requirements. It is important to minimize operating costs by maximizing efficiency and energy consumption. Choose energy-efficient equipment in order to reduce your impact on the environment and your utility bills.

Consider reliability and maintenance. Choose equipment that has a track record for reliability and ease of maintenance to minimize downtime and repair cost. Verify the availability of parts and service providers in your area. Standards must be met. Ascertain that all equipment meets relevant safety and hygiene regulations, such as FDA and USDA standards.

Consider the reputation of your vendor and their support. Select vendors who have a proven track record for providing reliable equipment with excellent customer service. Verify their service agreements and warranty policies.

Related: Launch Your Profitable Food Processing Business

Establishing Efficient Production Processes

Achieving efficient production processes is essential to maximizing output, minimizing costs, and ensuring consistent product quality. Streamlining processes can improve your bottom line.

Key Process Optimization Strategies

Standardize processes by creating standard operating procedures (SOPs). This will ensure consistency and repeatability. All employees should have easy access to SOPs that are well-documented. Lean manufacturing principles can be used to reduce cycle time, eliminate waste and increase overall efficiency. This could involve techniques like value stream mapping or 5S methodology.

Automate repetitive work to improve accuracy and throughput, reduce labor costs, and decrease labor costs. Automation ranges from simple conveyor systems up to sophisticated robotic assembly lines. Implement an inventory management system that minimizes storage costs, eliminates spoilage and ensures timely availability of material. Just-in-time management of inventory or ABC analysis may be involved.

Monitor performance metrics. Monitor key performance indicators (KPIs), like production volume, yield and defect rates to identify improvement areas. Data analysis can be used to guide decision-making.

Implementing Quality Control Measures and Food Safety Measures

In the food processing manfacturing sector, quality control and food safety is paramount to protect consumers and maintain brand reputation. For building trust and customer satisfaction, a robust quality control system will be essential.

Key Quality Control Measures

The first line of defense is raw material inspection. Check incoming materials for freshness, quality, and conformance to specifications. Reject materials that do not meet your standards. Regular testing of the process should be done. To monitor quality and identify issues, test product samples at various stages of production. You can catch issues early and stop them from getting worse.

Finished product inspection is essential. Before releasing a product to the market, inspect it for its appearance, texture, taste and packaging integrity. It is the last check you can do before a product reaches its consumers. Often, calibration and maintenance is overlooked. Calibrate and maintain your equipment regularly to ensure accuracy and reliability.

Documentation and traceability is also crucial. Keep detailed records for all quality control actions, which will allow you to trace products from the raw materials through to the finished product. It is important to be able to respond quickly in the event of a recall or any other issues relating food safety.

Food Safety Management Systems

Implement a Hazard Analysis and Critical Control Points system (HACCP), to identify and manage potential hazards during the entire manufacturing process. HACCP is an approach that uses a systematic process to identify, evaluate, and control food safety risks. To ensure safe food processing, hygienic conditions and proper handling of materials you should adhere to Good Manufacturing Practices guidelines. GMPs include a variety of topics from personal hygiene and equipment sanitation to hygienic conditions.

To prevent contamination and to maintain a clean and safe environment, implement comprehensive sanitation and hygiene programmes. Included in this should be regular cleaning and disinfecting of equipment and facility. Implement effective pest management programs to protect food from contamination and prevent infestations. It may be necessary to work with a pest control professional.

Set up procedures to manage allergens. This includes proper labeling, separation of materials and cleaning of equipment. It is important to control allergens in order to protect consumers with food allergies.

Navigating Regulatory Compliance

Food processing manufacturing is heavily regulated in order to protect consumers and ensure safe food. It is important to understand and follow these regulations in order to avoid fines and legal issues.

Key Regulatory Agencies

- Food and Drug Administration: FDA regulates the labeling and safety of food products within the United States.

- The United States Department of Agriculture regulates safety and labeling of meat products, poultry and eggs in the United States.

- European Food Safety Authority: Provides scientific advice on food safety and risk assessments in the European Union.

- Local and State Health departments: enforce food safety regulations and inspect food processing manufacturing facilities.

Key Regulatory Requirements

- Food Safety Modernization Act: This law requires food processing manufacturing plants to implement preventive measures to minimize food safety risks.

- Nutrition Labeling Education Act (NLEA). This law requires that food products be labeled with nutritional information to inform consumers about the product’s nutritional value.

- Fair Packaging and Labeling Act: This law requires accurate and informative labels on food products in order to avoid deceptive practices.

- Good Manufacturing Practices: Establishes standards on hygienic practices, equipment maintenance and food handling.

- Hazard Analysis and Critical Control Points: This requires food processing manufacturing plants to identify and control possible hazards.

NIIR Project Consultancy Services

It can be difficult to set up a manufacturing facility for food processing, but the right guidance will help you achieve success. NIIR Project Consultancy Services offers valuable assistance via its Market Survey cum Detailed Techno-Economic Feasibility Reports. These reports offer comprehensive insight into market potential, optimal production processes, raw materials requirements, plant design and detailed financial analysis. NPCS helps entrepreneurs assess their ventures thoroughly to ensure they are prepared for the challenges in the food industry and can capitalize on opportunities.

Find Best Idea for Yourself With our Startup Selector Tool

The conclusion of the article is:

It is not easy to set up a food processing manufacturing facility . Entrepreneurs can improve their chances of success by conducting a thorough market study, developing a comprehensive marketing plan, choosing the right location, designing a facility that is efficient facility, purchasing appropriate equipment, setting up effective processes, implementing effective quality control measures and navigating regulatory compliance. With resources such as NPCS, aspiring manufacturers of food can make their visions a reality and contribute to an ever-changing landscape in the food processing industry.