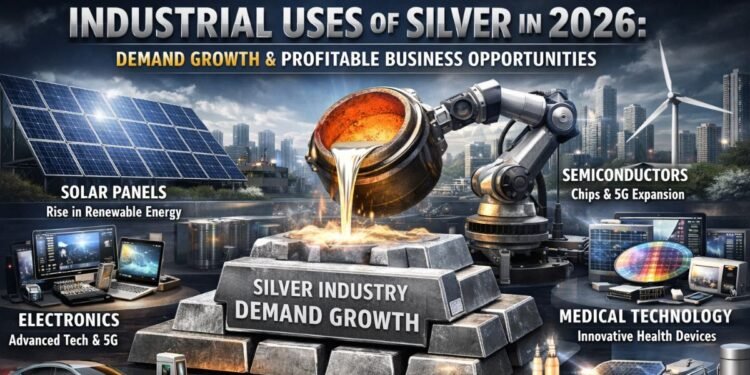

Industrial Uses of Silver now exists beyond its traditional uses for jewelry and investment purposes. The metal now serves as a key industrial resource which gained global economic significance by the year 2026. The modern world infrastructure uses silver throughout its essential systems which support renewable energy, electric vehicles, electronics, railways, and healthcare.

The industrial silver market operates with steady demand because it depends on permanent market expansion while the speculative commodities market functions through speculative trading activities. As countries expand electrification, clean energy, smart infrastructure and digital manufacturing, the natural increase in silver consumption happens. For entrepreneurs and MSMEs this provides long-term, stable and scalable business opportunities.

Table of Contents

ToggleRead More: Handbook on Rare Earth Metals and Alloys (Properties, Extraction, Preparation and Applications)

Why Silver Is an Important Industrial Metal

The special physical and chemical properties of silver metal create vital industrial uses for the metal. The metal provides us with:

- The highest electrical conductivity of any metal

- Excellent thermal conductivity

- Strong resistance to corrosion

- Natural antimicrobial properties

Silver functions as an essential material for critical performance requirements because of its exceptional properties. The use of silver replacement materials in high-current or high-precision systems leads to lower performance and shorter system lifetime. This makes the industrial demand either relatively stable and not easily substitutable.(Industrial Uses of Silver)

Infrastructure Expansion Feeding Silver Demand

Government-led infrastructure programs are major contributors to the consumption of industrial silver. Modernization of transport systems, growth of renewable energy, installation of smart grids need silver based components for the electricity.

Organizations like the Government of India and Indian Railways are investing in electrified transport networks, signalling systems and high capacity power distribution. These projects need electrical contacts, relays, and control systems to be made durable, where silver plays a central role.

To entrepreneurs, infrastructure-driven industries provide:

- Long-term visibility of a project

- Repeat orders from OEMs

- Stable demand cycles

- Reduced reliance on the vagaries of the retail market

Silver in Electrical contacts and Switchgear

One of the largest industrial uses of silver is in electrical contacts. Silver alloys are found in relays, circuit breakers and switchgear and even in high current connectors.

These components are necessary in:

- Railway signalling systems

- Industrial automation panels

- Power distribution equipment

- EV charging stations

Silver is thus preferred because it has low energy loss, it is resistant to arcing during switching and it performs reliably over millions of cycles.(Industrial Uses of Silver)

Business opportunity:

MSMEs can be used to produce precision silver contact tips and assemblies for OEM suppliers. This segment is more concerned with quality control and technical accuracy rather than huge capital investment and can be applied to specialized manufacturing units.

Solar Panels and Renewable Energy - Silver

Silver paste is an important material in photovoltaic (PV) cells. It develops conductive gridlines to gather the electricity that is produced from sunlight.

While manufacturers are working to reduce the amount of silver used per solar cell, the amount of silver used is continuing to increase because of:

- Rapidly growing global solar capacity

- Governments are raising renewable energy targets

- Rooftop and utility-scale installations are taking off

Startup opportunities in this segment include:

- Conductive silver paste formulation.

- Silver ink manufacturing

- Recycling silver from end-of-life solar panels

The clean energy transition process creates export opportunities for this region which contains valuable export resources.(Industrial Uses of Silver)

Silver in Electronics and Printed Circuit Boards

Electronic companies represent a major market which uses silver in their manufacturing processes. It is used in printed circuit boards (PCBs), conductive coatings, semiconductor packaging and high performance connectors.

As electronics manufacturing grows because of automation, smart electronics and digital infrastructure, so does the demand for silver.

Silver as electronics:

- Increasing the conductivity of small circuits

- Improving the reliability of the signal

- Supporting high-speed data systems

Entrepreneurial scope is present in:

- Silver plating services

- Conductive ink production

- Silver extraction from electronic waste

Urban mining and recycling are companies that are especially promising because electronic scrap contains recoverable precious metals, including silver.(Industrial Uses of Silver)

Silver in Healthcare and Medical Devices

Silver functions as an antibacterial agent which medical professionals use in healthcare applications. The material serves multiple purposes within surgical instruments and wound dressings and catheters and diagnostic gear and antimicrobial coatings.

The healthcare industry expansion and medical device manufacturers production capacity growth drive rising demand for medical-grade silver components. The segment generates superior financial outcomes because it requires businesses to fulfil both quality standards and regulatory compliance obligations.

Entrepreneurs venturing into this area must pay attention to certification, precision processing and constant quality control.(Industrial Uses of Silver)

Silver for EV's and Charging Infrastructure

Electric vehicles contain more silver than conventional vehicles due to the heavy electrical systems. Silver is present in battery management system, high current connectors, power electronics and charging hardware.

The worldwide electric vehicle market now drives silver demand because of its rapid growth which creates a significant increase in silver needs according to market predictions.

Potential areas of business include:

- Manufacturing EV electrical connectors

- Supplying charging station components made with silver

- Producing High current power control modules

This is a long-term growth industry in line with clean mobility objectives.(Industrial Uses of Silver)

Why Industrial Silver Demand Will Continue To Increase

The choices of growth drivers behind silver are structural and long-term. They include electrification of transport, renewable energy expansion, electronics manufacturing growth, EV ecosystem development and healthcare modernization.

Some of the reasons why demand will remain strong:

- infrastructure investment is growing globally

- Renewable energy targets are growing

- Penetration of Electronics in all sectors

- Whereas silver has poor substitute performance

This makes industrial silver a strategic material as opposed to a speculative commodity.(Industrial Uses of Silver)

Best Business Opportunities for MSMEs in Silver

Entrepreneurs looking to get into this sector should look at value addition and not raw metal trading. Some high potential areas include:

- Manufacturing of Silver electrical contact

- Recycling and refining of silver from e-waste

- Conductive services, silver ink and paste production

- Silver plating services coating services

These segments are a combination of stable demand and the potential for scalability in growth.(Industrial Uses of Silver)

Conclusion

Silver evolved from its historical status as a precious metal to become a crucial material which underpins all electric-powered systems. The metal maintains industrial need because it serves multiple functions in renewable energy systems and electric vehicles and electronic devices and healthcare and infrastructure.

Small and micro-businesses should focus more on processing, precision manufacturing, recycling, and technology-based applications. As global electrification and clean energy investment accelerate, industrial silver businesses are positioned for long-term, manufacturing-led growth.(Industrial Uses of Silver)

Frequently Asked Questions (FAQ)

Q1. Is the demand for industrial silver stable?

Yes. Demand is associated with infrastructure, renewable energy, electronics and healthcare – all of which have long-term growth.

Q2. Can startups get into manufacturing silver without mining?

Yes. Most of the lucrative opportunities are in processing, recycling and component manufacturing.

Q3. What is the largest industry that uses silver today?

Solar photovoltaic manufacture and electric components are among the biggest consumers.

Q4. Is it a good business to recycle silver?

Yes. Recovering silver from electronic scrap as well as industrial waste provides generous margins and promotes sustainability.

Q5. Is silver-based manufacturing appropriate for MSMEs?

Yes. Precision electrical contacts, Silver plating, Conductive Inks, and Recycling units are great for MSME scale investment.