Introduction: Maize Wet Milling Plant in India

India’s agro-processing sector is on a structural transformation. The traditional emphasis on trading in primary agricultural commodities is gradually giving way to the value-added industrial manufacturing. This change is being fuelled by increasing domestic consumption, solid policy support for food processing and pharmaceuticals, and a strategic need to decrease reliance on imports. Within this changing ecosystem, maize has become one of the most commercial important raw materials for downstream industrial processing.

Integrated maize wet milling units – facilities to convert maize into starch and advanced derivatives such as liquid glucose, dextrose monohydrate and sorbitol – are a scalable and capital-efficient manufacturing opportunity for startups and MSMEs. With a massive domestic raw material availability, and growing industrial demand, maize wet milling has long-term potential for sustainable growth.

India's Maize Production Opportunity & Processing Gap

India is one of the world’s largest producers of maize with its annual production standing at over 36 million metric tonnes. The crop is grown in a wide range of agro-climatic zones to ensure that production is available year-round and that prices are stable compared to many other agricultural commodities.

In spite of this strong production base, industrial processing of it by wet milling is not well developed. At present, an estimated 20-25% of India’s maize production is managed into industrial derivatives. Nearly 55 – 60% is used for poultry and animal feed industry and 10 – 15% for direct consumption in food. This imbalance has led to a continuing shortage of refined maize derivatives, in particular those that are pharmaceutical and food grade.

As a result, several downstream industries still rely on imports in spite of plentiful maize at home. This structural gap between agricultural production and industrial processing represents an attractive opportunity for new manufacturing investments.(Maize Wet Milling Plant in India)

Industrial Demand for Maize Based Derivatives

Maize wet milling yields a variety of products with high added value that are important inputs to several fast-growing industries.(Maize Wet Milling Plant in India)

Native and Modified Starch of Maize

Maize starch is widely used in textile warp sizing, paper and packaging adhesives, corrugated board and pharmaceutical tablet formulation. In pharmaceuticals, starch is used as a binder, disintegrant and filler and is therefore a key excipient.(Maize Wet Milling Plant in India)

Liquid Glucose

Liquid glucose is widely consumed in confectionery, filling of bakeries, beverages, ice creams and frozen desserts. Its ability to prevent crystallization, improve texture and extend shelf life makes it indispensable for food manufacturers.(Maize Wet Milling Plant in India)

Dextrose Monohydrate

Dextrose monohydrate plays an important role in:

- Intravenous fluid/ injectable manufacturing

- Fermentation Based Production Of Antibiotics, Enzymes, Organic Acids

- Nutraceuticals and clinical nutritional products

Sorbitol

Sorbitol (produced by catalytic hydrogenation of glucose syrup) is a high demand polyol and is widely used in:

- Toothpaste and mouth care formulations

- Cosmetics and personal care products

- Vitamin syrups Nutraceutical preparations

The steady growth of consumption of processed food, pharmaceutical manufacturing, and personal care products in India is the main cause of steady demand for these derivatives.(Maize Wet Milling Plant in India)

Import Dependency & Import Substitution Opportunity

Despite an increase in domestic consumption, large quantities of sorbitol and specialty starches are still imported in India. The main reason is that there is limited capacity available domestically that can meet pharmaceutical grade purity, consistency and regulatory requirements.(Maize Wet Milling Plant in India)

This import dependence raises procurement costs and leaves the manufacturers vulnerable to supply chain disruptions worldwide, foreign exchange volatility and long lead times. Pharmaceutical clusters of Gujarat, Telangana, Maharashtra, Himachal Pradesh are extremely affected, because uninterrupted access to excipients is critical for uninterrupted production.(Maize Wet Milling Plant in India)

For the startups and MSMEs, this is a classic import substitution opportunity. Setting up decentralized maize wet milling units near the large consumption hubs has several benefits:

- Reduce logistics and transportation costs

- Faster delivery cycles (for industrial clients)

- Improved Supply Chain Reliability

- Better customer relationships via regional presence

Market Structure and Industry Gaps

India’s organized maize processing industry consists of a few large, established players with the capacity to supply bulk volumes to national and international customers. However, their production facilities are concentrated in small geographic areas. This concentration is responsible for regional supply gaps, especially of pharmaceutical and food-grade derivatives that require flexible batch size and consistent quality.(Maize Wet Milling Plant in India)

MSME-scale integrated wet milling units can be successful in addressing these gaps by focusing on:

- Region and cluster based demand

- Customized specifications for industrial clients

- Faster response times, as opposed to large centralized plants

This localised manufacturing approach allows smaller players to compete well in the face of large incumbents.(Maize Wet Milling Plant in India)

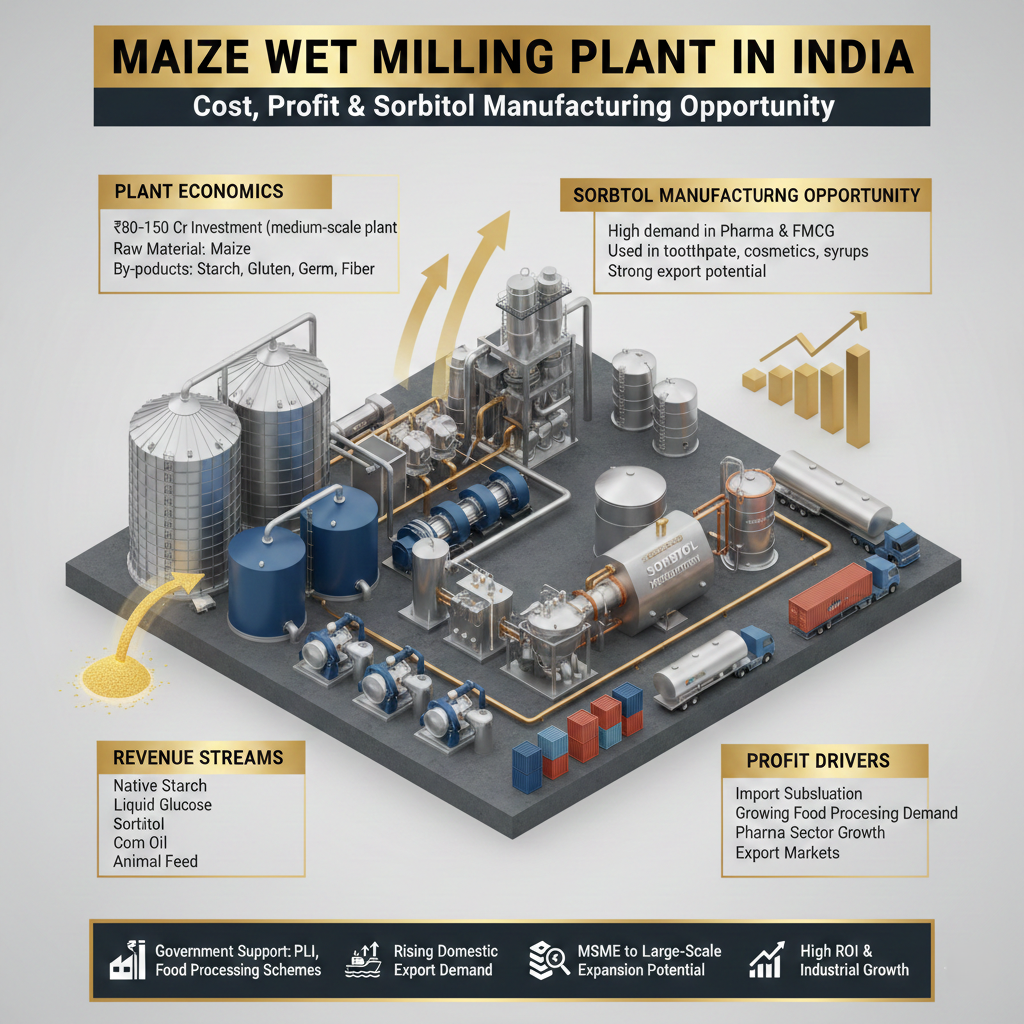

Techno-Economic Analysis of an Integrated Wet Milling Unit

An integrated maize wet milling plant is operated in well-established and proven processing stages:

- Steeping: Cleaned kernels of maize are steeped in water with controlled levels of sulfuric dioxide to soften the grain and make it easier to separate the kernels.

- Grinding and Separation: The softened-grain milling procedure splits the main kernel components, including starch, gluten, germ, and fiber.

- Starch Refining: The process includes the washing and refining of the starch slurry to meet the requisite degrees of purity.

- Conversion Processes:

- Enzymatic liquefaction and saccharification to give glucose syrup

- Crystallization of glucose to form dextrose monohydrate

- Catalytic hydrogenation is the conversion of glucose syrup into sorbitol

In addition to the primary products, valuable by-products such as maize germ oil, gluten meal and fibre feed have a significantly positive effect on the overall plant economics. These by-products are in demand from the edible oil, animal feed and poultry sectors.(Maize Wet Milling Plant in India)

Support and Incentives from Government Policy

The Ministry of Food Processing Industries operates multiple schemes which the Government of India uses to promote agro-processing investments. Major programs include the following:

- Pradhan Mantri Kisan Sampada Yojana (PMKSY)

- Micro Food Processing Enterprises (PM-FME) Scheme

- Argo Processing Cluster Infrastructure Scheme

The programs offer financial assistance to support the acquisition of plant and machinery and the construction of infrastructure and the establishment of complete processing facilities. For startups, such incentives have a tremendous capital alleviation and enhance project viability.(Maize Wet Milling Plant in India)

Market Outlook and Startup Investment Opportunity

India’s maize derivatives market is likely to show continuous growth, supported by:

- Rising consumption of processed food

- Growth of domestic pharmaceutical manufacturing

- Growth of personal care products and oral care products|

- Increasing demands from fermentation-based industries

Integrated maize wet milling units are associated with a number of strategic advantages for startups:

- Abundant Availability of Domestic Raw Material

- Diversified product portfolio that balances the revenue risk

- Strong policy and financial support by the government

- Clear potential of import substitution, especially in sorbitol

With proper site selection, technology adoption, and adherence to quality and regulatory requirements, these units can become scalable, long-term manufacturing businesses.(Maize Wet Milling Plant in India)

Conclusion

Integrated maize wet milling units are an interesting manufacturing opportunity in the changing Indian agro-industrial scenario. By filling the structural gap between maize production and industrial processing, startups and MSMEs are able to develop sustainable businesses in line with national priorities of import substitution, value addition, and industrial growth. The execution must be done in such a way that will bring maize wet milling to a level of a seeding plant.-scalability for ongoing future manufacturing in India.(Maize Wet Milling Plant in India)

Frequently Asked Questions (FAQs)

Is integrated maize wet milling plant is profitable in India?

Yes. Multiple revenue streams, high value derivatives and saleable by-products make integrated wet milling units very financially attractive.

Why is sorbitol manufacturing so attractive?

Domestic capacity is still limited and imports are continued. Local production has the advantage of cost and security of supply for downstream industries.

What scale is appropriate for MSME Entrepreneurs?

Medium-scale integrated plants represent an ideal trade-off between capital investment and market demand.

Are there government subsidies available?

Yes. Eligible projects can avail capital and infrastructure under different MoFPI schemes.

Can startups compete with the big maize processors?

Yes. Regional emphasis, swift delivery, customization and customer proximity is what enables MSMEs to compete effectively.(Maize Wet Milling Plant in India)