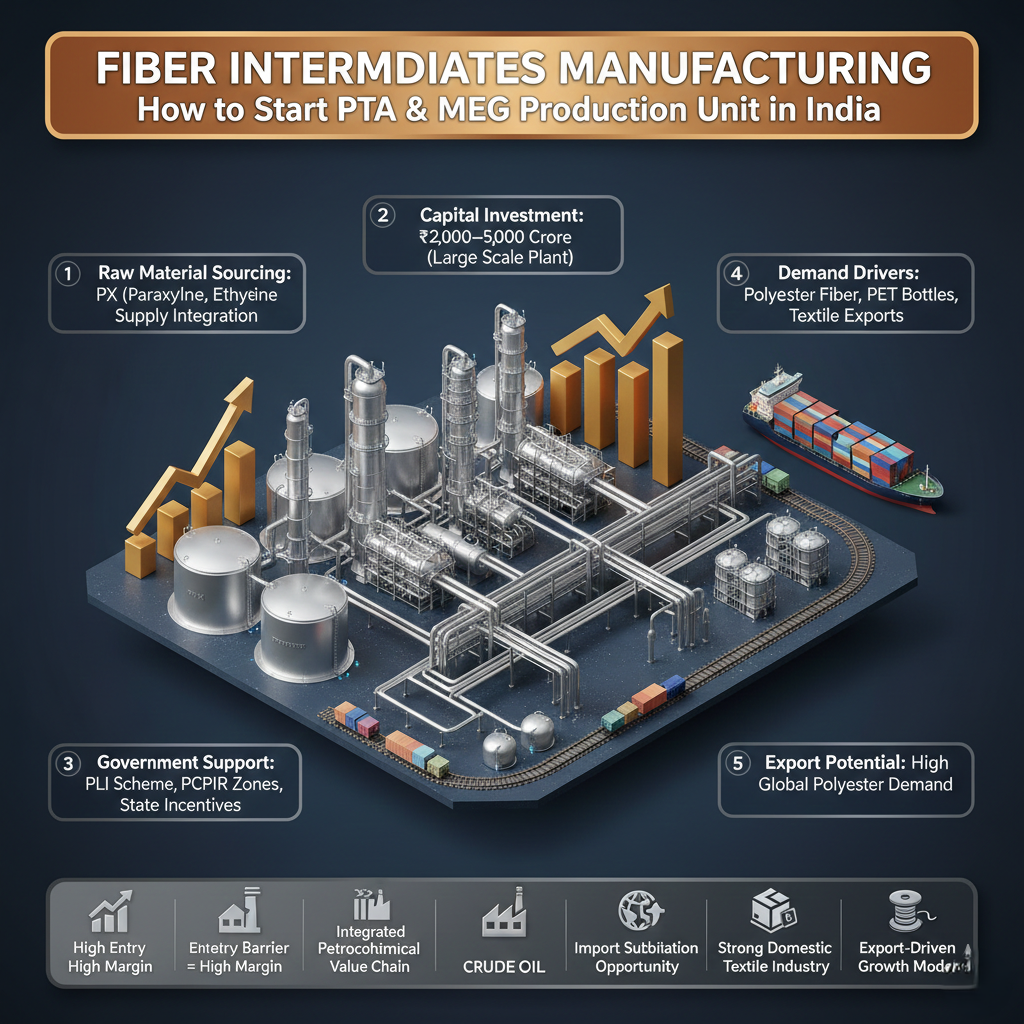

The petrochemical industry in India has also experienced a very strong growth due to the increased domestic demands, increased exports and government programs that Favor growth of industries. The Fiber Intermediates Manufacturing , especially Purified Terephthalic Acid (PTA), and Mono Ethylene Glycol (MEG) are some of its other segments, but have become a promising niche in which the industry has high potentials and investment opportunities. The Annual Report 202526 by the Ministry of Chemicals Fertilizers has reported a figure of around 12.2 percent of the total production of petrochemicals in India by fiber intermediates, indicating a long-term and increasing production trend.(Fiber Intermediates Manufacturing)

Fiber Intermediates: Understanding.

Fiber intermediates are crucial petrochemical items that serve as raw materials in the establishment of polymers that are utilized in the creation of polyester. These two major intermediates are:

- Purified Terephthalic Acid (PTA): This is one of the major building blocks of polyester fibres and PET resin.

- Mono Ethylene Glycol (MEG): It is a reaction with PTA to form polyethylene terephthalate (PET), which is converted to polyester fibres, filament yarn, PET resin, and technical textiles.

PTA and MEG are key in the manufacturing of a polymer, polyester which is the most dominating segment of the Indian synthetic textile market because it is durable, versatile and cost effective.(Fiber Intermediates Manufacturing)

Large Suppliers of Fiber Intermediates.

Large integrated companies have already taken control of the Indian fibre intermediates industry and are running large upstream production plants:

- Reliance Industries Ltd.

- Indorama Ventures

- Indian Oil Corporation

Although these players deal with large-scale production of PTA and MEG, downstream production sections of polymer blending, copolymer preparation, and additive formulation can be scaled down to provide an opportunity to MSMEs and new entrants.(Fiber Intermediates Manufacturing)

Read More: Startup Selector

PCPIR Clusters Strategic Advantage.

The Petroleum, Chemical and Petrochemical Investment Regions (PCPIRs) in India are developing the best infrastructure to facilitate the manufacturing of chemicals. Key clusters include:

- Dahej PCPIR, Gujarat

- Pradeep PCPIR, Odisha

- Visakhapatnam Kakinada PCPIR, Andhra Pradesh.

These clusters offer:

- Ordinary effluent treatment facilities.

- Shared utilities Steam, power, and cooling, water.

- Port connectivity on import-export.

- Environmental compliance support.

Locating manufacturing facilities in the clusters helps decrease the cost of logistics and guarantees the stable supply of textile and packaging industries which have tight production programs.(Fiber Intermediates Manufacturing)

Downstream Fiber Intermediates Opportunities in MSME.

Rather than investing in the capital-intensive production upstream, entrepreneurs may concentrate on modular and scalable downstream processes, such as:

- Polyester Feedstock Blending Plants: Blending of both PTA and MEG to produce tailor-made feedstock blends to the textile mills.

- PET Copolymer Preparation Units: This is the production of specialty PET resin to be used in the packaging, filament yarn, and industrial processes.

- Industrial Yarn-Grade Additive Formulation: Improving fibre properties to become durable, UV resistant and thermal resistant.

- Fiber-Grade Stabilizer Production: Enhancing polymer behaviour to enhance high-performance technical fabrication.

The manufacturing process is generally a blend that is controlled, and catalytic and stability modified, as well as quality standardized to the BIS norms. Access to common facilities in chemical properties eases operations and decreases set-up sophistication.(Fiber Intermediates Manufacturing)

Read More: PET Preform

Financial and Investment Prognosis.

The chemical industry in India has received a lot of foreign direct investment (FDI) in the last ten years, which can be regarded as a confidence of investors. Fiber intermediates offer:

- Constant industrial demand during the year.

- Good connection with export-oriented textiles.

- Increasing domestic use of polyester.

- Indian refiners are able to provide raw materials.

Government programs like the Technical Textiles Mission and production based incentive schemes are likely to increase the capacity to produce more polyester hence a steady demand in the PTA and MEG derivatives.

Export Potential: Indian manufacturers can provide modified intermediates and specialty blends to the international polyester producers that are ready to source reliable and diversified products with improved infrastructure (ports).

Important Facts to be considered when establishing Fiber Intermediates Plant.

The investors must consider: when planning a downstream fiber intermediates unit.(Fiber Intermediates Manufacturing)

- Raw Material Procurement: Obtain PTA and MEG either domestically through the refineries or through imports.

- Location Choice: PCPIR clusters give cost and logistic benefits.

- Regulatory Compliance: Compliance with the environmental, safety and BIS quality standards.

- Machinery & Equipment: Invest in modular blending and stabilization as well as copolymer processing units.

- Market Access: forge B2B relationships with textile manufacturers, packaging companies and industrial yarn manufacturers.(Fiber Intermediates Manufacturing)

Benefits of Investment in Fiber Intermediates.

- High Demand: In linked with increased textile, packaging, and technical fabric industries.

- Scalable Investment Downstream units can be expanded gradually with reduced capital investment.

- Specialty blends: Specialty blends may also be exported to international producers of polyester.

- Industrial Synergy: Installed in PCPIR clusters to be more easily integrated with the supply of raw materials and utility.

- Stable Returns: Polyester intermediates are demanded by the industry throughout the year and thus guarantee stable revenues.(Fiber Intermediates Manufacturing)

Future Growth Outlook

The Indian polyester market is expected to experience growth within the next decade which will be promoted by:

- Increasing local demand of garments and industrial textiles.

- Diversification of technical fabrics and performance fabrics.

- More use of PET in packaging of FMCG and pharmaceutical.

- Policies on government favourability towards manufacturing and export of chemicals.

This structural development provides a long-run demand queue of PTA and MEG, and thus fiber intermediates production is a well-timed investment.(Fiber Intermediates Manufacturing)

Conclusion

The production process of fiber intermediates establishes a link between India’s petrochemical industry and its textile industry, which together serve as major forces driving industrial growth. The segment provides long-term investment prospects through its 12.2% market share, which results from its high operational efficiency and increasing polyester demand.(Fiber Intermediates Manufacturing)

Entrepreneurs who operate business ventures in PTA and MEG processing facilities that exist within PCPIR clusters can use the following advantages:

- Strong infrastructure support

- Consistent industrial demand

- Modular and scalable expansion opportunities

- Access to export markets

The fibre intermediates processing sector offers attractive business opportunities to investors and MSMEs who aim to create manufacturing facilities in India because the petrochemical sector is undergoing strategic development through this process.(Fiber Intermediates Manufacturing)

Frequently Asked Questions (FAQ)

- What are fibre intermediates?

Fiber intermediates are petrochemical products like PTA and MEG, which serve as raw materials for polyester fibres, PET resin, and technical textiles. - Why is this sector growing in India?

Growth in polyester textiles, technical fabrics, and PET packaging is driving strong demand for PTA and MEG. - Can MSMEs enter this business?

Yes, particularly in downstream blending, copolymer preparation, and specialty additive formulation. - Where is the best location to set up a plant?

PCPIR regions such as Dahej, Pradeep, and Visakhapatnam–Kakinada offer infrastructure, port connectivity, and regulatory support. - Does the sector have export potential?

Yes. Modified polymer blends and specialty fibre-grade intermediates can be supplied to international polyester producers seeking reliable and diversified sourcing.(Fiber Intermediates Manufacturing)