Start your own Surgical Cotton Business

Surgical cotton or Absorbent cotton is mostly used in medical departments such as nursing homes, hospitals, clinics and also at homes. This cotton is not similar to the normal cotton rolls found in the market, it is better absorbent of high fluid and it offers better performance among the masses. The raw materials of this cotton go through many processes so that the hydrophilic character is rendered. Also in this process, it becomes free from all the outside impurities which make it suitable to be used in hygiene applications and surgeries.

Related Projects:- Surgical, Medical Plastics, Medical Disposables, Disposable Medical Products used in Hospitals

Uses of This Cotton

- Mostly it is useful in surgical dressings and in many medical purposes.

- Apart from being used on medical purposes, it has also a major use in the making of sanitary napkins or pads.

- Good quality of this kinda cotton is also used by beauticians to remove dirt and makeup from skin.

- This is used for padding quilts and other clothing stuff. Also, it has some household applications too.

Characteristics of Surgical Cotton

- The nature of this cotton is hydrophilic.

- It is all kinds of external impurities free.

- It may be sterile or non-sterile in some cases.

- It uses bleached

Related Books: - Disposable Products (Medical, Surgical, Thermocol, Plastic, Paper, Domestic And General Products)

Standards of Surgical Cotton Virgin cotton is used as a raw material. It absorbs huge fluid in less than 5-10 seconds. It can hold fluid almost 24 times of its own weight. It includes 0.5% ether soluble substances. Contains 0.4% (maximum) sulfated ash. Contains no mercury elements. Has no odor. Surgical cot

Manufacturing Process of Surgical Cotton

Opening and Cleaning Firstly raw cotton materials or bales are opened and loosened. Also in this process, all the foreign particles are removed. Bleaching Then the washed and clean cotton is bleached to remove all the effects of chemical treatments. Chemical Removal The bleached cotton is washed again to remove all the chemicals to make it completely chemical-free. Drying Then the wet cotton is dried using the industrial dryer or sun rays. Lapping After that, the dried cotton is sent to the blower room to make laps of it. Carding The laps are fed inside the carding machine. Rolling Then the resulting cotton is compressed to be rolled into desired size cotton rolls with some packaging paper. Weighing and Cutting Then finally the cotton rolls are weighed and cut accordingly. And now it is finally ready to seal and delivered.

Related Videos: - Industrial, Medical and Specialty Gases Manufacturing Project Ideas

Market Potential

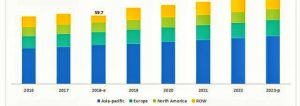

The estimated demand for surgical cotton is growing at a rate of 10% per year access the world. There is a huge exported potential for surgical cotton in countries such as India, the US, EU, and Japan. According to the experts, within the next 5 years, approx 3-4 million bales will be required to fulfil only the domestic demands. Also, more would be needed for the export market.

The demand for surgical cotton is very much related to the population and expansion of public health services. So with the development of medical facilities in the world, the surgical cotton industry is also growing rapidly.

Related Project:- Surgical Cotton

Lastly, Here is everything you need to know about the Surgical Cotton industry. For more information, you can find all the related data from the internet.

NK_20

Tags:- #DetailedProjectReport #businessconsultant #BusinessPlan #feasibilityReport #NPCS #StartupProject #howtostartbusiness #ProjectReprot #ConstructionMarket #surgicalcotton #mendicatedcotton #CottonManufacturing #CottonProduction #CottonBusinessPlan #CottonBusiness #CottonMarket