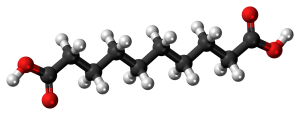

Sebacic acid is a derivative of castor oil. In the industrial setting, sebacic acid and its homologues such as azelaic acid can be used as a monomer for nylon 610, plasticizers, lubricants, hydraulic fluids, cosmetics, candles, etc. Because of the by-products formed, the yield of sebacic acid is necessarily low, and in practice, yields of 50–55% (based on the castor oil) are considered to be good.

Related Projects:- Chemicals (Organic, Inorganic, Industrial) Projects

Sebacic acid may also be produced by an electro oxidation process developed by Asahi Chemical Industry in Japan (Yamataka et al., 1979), and also piloted by BASF in Germany. It produces high purity sebacic acid from readily available adipic acid. The process consists of three steps. Adipic acid is partially esterified to the monomethyl adipate. Electrolysis of the potassium salt of monomethyl adipate in a mixture of methanol and water gives dimethyl subacute. The last step is the hydrolysis of dimethyl subacute to sebacic acid.

Sebacic Acid from Castor Oil:

Sebacic acid is manufactured by heating castor oil to high temperatures (about 250oC) with alkali. This treatment results in saponification of the castor oil to ricin oleic acid that is then cleaved to give capryl alcohol (2-octanol) and sebacic acid. The process is based on the caustic oxidation of castor oil. The type of reaction used affects the purity of the sebacic acid; the modern conversion technology results in a higher purity (There is an older domestic conversion which uses a mixture of molten caustic soda and caustic potash). The modern method, which also claims higher yields, uses castor oil and molten caustic. The type of reaction used affects the purity of the sebacic acid, and the modern conversion technology is reported to yield sebacic acid with a higher purity.

Market Analysis across the World:

· The global sebacic acid market size was valued at USD 245.6 million in 2017. It is projected to expand further at a CAGR of 3.7% over the forecast period. Growing demand for biodegradable polymers due to their eco-friendly nature is expected to drive the global market. The demand for sebacic acid is also supported by favorable government regulations across the globe.

Related Books: Chemical Technology (Organic, Inorganic, Industrial), Fine Chemicals

· It is mainly derived from castor oil and is classified as a second-generation derivative. It accounts for a market share of about 27% in the gen II castor oil derivatives market. It is majorly used in the manufacturing of biodegradable plastics, and nylon 6.10, which have major applications in textiles, automotive, and packaging industries.

Related Videos: Chemicals (Organic, Inorganic, Industrial)

· The U.S. market for the chemical is majorly driven by its use as a precursor to polymers and lubricants and growing demand in cosmetic products. Increasing population coupled with growing awareness about personal health and skin care products is augmenting the demand for good quality cosmetics. This, in turn, is boosting the market growth. Moreover, wide usage in several end-use industries, such as lubricants, paints, and adhesives, and polymers, is contributing to the product demand.

· Emerging economies, such as China, India, Japan, and Brazil, are investing heavily in chemical production to fulfill the growing demand. This chemical is classified as non-toxic and non-hazardous substance by the ECHA and REACH and hence also provides easy, as well as affordable, trade between different regions. Growing urban population, majorly in China and India, has led to a rise in demand for cosmetic products. Governments in these regions have undertaken several initiatives to develop green chemicals that provide a faster yield of castor seeds.

Conclusion:

One of the project report prepared by NPCS is on Sebacic Acid from Castor Oil. The project report by NPCS covers all the major aspects of a business such as analyzing the market, confirming availability of various necessities such as plant & machinery, raw materials to forecasting the financial requirements. Many engineers, project consultant & industrial consultancy firms in India and worldwide has taken benefit from the project report by NPCS to analyze the business aspects.