Electric motors are crucial tools used to transform electricity into energy in a wide range of sectors. Due to the interaction between the motor's field of force and electrical phenomena within the motor winding, these motors produce motility forces. Despite how simple an electrical motor's function may seem, a lot of work goes into planning and defining these motors for various uses.

Visit this Page for More Information: Start a Business in Electronic Industry

However, buying a new electric motor is more expensive than getting it repaired. Often electric wires in the motor get burnt and repairing them requires a cost. However, it is still considered a cost-effective option. Rewinding or repairing electric motors includes unwinding old rotor and stator and replacing as well as winding the new ones. Often consumers go with the rewind motors to save money. Henceforth, this business is always beneficial for start-ups because it also helps in saving the environment and raw materials in making new motors.

NPCS is always available to help entrepreneurs get into the right business that is profitable and cost-effective in managing. Here is the list of all information that you may need before starting a rewinding business of burnt electric motors.

Related Business Plan: Electrical, Electronic Industries and Power Projects

Indian Market

With a CAGR of 6.32% from 2019 to 2024, the global burnt electric motors sales market, which was valued at USD 99.95 billion in 2018, is expected to generate market returns of USD 144.37 billion.

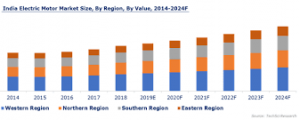

The country's rapidly expanding end-user industries and construction activities are the main drivers of the electric motor market in India. The main markets for electric motors are Gujarat, Maharashtra, and Madhya Pradesh, and they are essential for driving market income. During the projected period, a rise in government efforts like the Green Energy Corridor in Gujarat, Madhya Pradesh, and Maharashtra, is anticipated to contribute significantly towards old and new electric motors.

Read Similar Articles: ELECTRONIC PROJECT

Due to the presence of a significant number of participants, including large manufacturing corporations and medium-sized businesses, the Indian market for electric motors is fragmented. One of the main emphasis areas of the major manufacturers functioning in the Indian electric motor market is innovation and technical progress, such as energy-efficient motors with significant power-saving capabilities. The use of electric motors is anticipated to rise soon in several important application areas across the country, including transportation, industry, HVAC equipment, and residential appliances.

This will increase the demand for second-hand rewound electric motors as well as more industries will be looking for motors, they will try to look for a method to save money by purchasing rewound burnt electric motors.

By launching programmes like Make in India, the Smart City Mission, the AMRUT, affordable housing, and others, the Indian government is significantly contributing to the growth of the electric motor market. The industry outlook has been favourably impacted by the industrial tendency to improve the current electrical infrastructure. Governments in India are continually discussing new opportunities for cooperation to enhance the energy supply for end-user industries.

Watch Video: Electrical and Electronics Products Manufacturing Industries

Registration and Licence Required

For licence you will have to first provide:

· The list of motors that you will rewind, based on which further documents will be needed. (Single phase, three phases, low and high speed, etc.)

· State clearly and give supporting evidence if your company is under the Joint venture, Partnership, or Local representation.

· Trade Licence Certificate

· GST and VAT certificate

· NOC from the electricity supply.

· NOC from State Pollution Board

· MSME Udyog Aadhaar Certification

· ISO Standard Certificate

· BIS Certificate

· Maintenance of Health and Safety Standards of Employees.

Related Feasibility Study Reports: Electrical, Electronic Industries and Power Projects

Raw Material

1. Copper is the most common material utilised to make motor windings. This is mainly because of its excellent electrical conductivity and affordable price.

2. Aluminium is another common material for motor winding design. When lightweight materials are required, aluminium is a superior option due to its density, which is (nearly one-third that of copper).

3. Silver wrapping wires are more electrically conductive than their copper and aluminium counterparts. However, silver wires are significantly more expensive than comparable copper or aluminium wires when they are fresh off the production line.

4. In recent years, copper and aluminium winding wires are replaced with carbon nanotube fibres and yarns, which are now gaining favour in the electric motor sector. Compared to copper cables, these fibres are stronger and more flexible. Additionally, they are lighter than a comparable copper wire by nearly nine times.

Finances

The financials are a crucial component of any business arrangement. By entering your anticipated monthly and annual income, the business plan builder tool makes it simple to create your money charts.

Be careful to predict the numbers in line with your goals, if you don't know the numbers because the firm is a rewinding firm. If you're looking for finance, it's also advised to have a clear breakdown of your funding requirements. This free business planning guide can help you with just that.

Read our Books Here: Books