Humans have utilised glass for thousands of years. It was discovered in 3500 BC-era archaeological sites. Glass manufacture has changed dramatically since that time. Soda ash is one of the essential components used in the production of glass. Yet, the ecology may suffer as a result of soda ash production. Hence, it is essential to produce glass using soda ash in a sustainable manner in order to safeguard both the environment and the industry's future.

Describe Soda Ash.

Sodium carbonate, or soda ash, is a powdery white substance. It serves as a raw ingredient for several industries, including the production of glass. It is created using the Solvay method from trona ore or sodium-rich brines. In the Solvay process, sodium chloride, ammonia, and carbon dioxide are combined to create sodium bicarbonate. When the sodium bicarbonate is heated, soda ash and water are created.

Start a Business in Glass Manufacturing Industry, Click Here

The chemical industry receives a lot of support from the soda ash sector. The soda ash market was estimated to be worth $22 billion globally in 2020. From 2021 to 2028, it is anticipated to expand at a compound annual growth rate (CAGR) of 2.6%.

Making Glass using Soda Ash

A crucial component in the production of glass is soda ash. Silica, the main ingredient in glass, is used to lower its melting point. The melting point of silica is lowered from 1700°C to roughly 1200°C when soda ash is added. In order for the manufacturing process to be energy-efficient, this lower temperature is required.

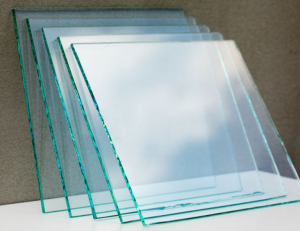

Depending on the type of glass being manufactured, glass producers employ several forms of soda ash. For instance, container glass—used for bottles and jars—needs a different kind of soda ash than flat glass, which is used for windows and mirrors.

There are certain environmental issues with using soda ash to make glass. Significant volumes of greenhouse gases, mainly carbon dioxide, are produced during the manufacturing of soda ash. The most popular technology for making soda ash, the Solvay process, also generates a lot of waste, including ammonia and calcium chloride.

Sustainable Soda Ash Production

The development of sustainable manufacturing techniques has been motivated by the environmental impact of creating soda ash. One strategy is to power the manufacturing process with renewable energy sources. Solvay, a manufacturer of soda ash, has pledged to acquire 30% of its energy from renewable sources by 2030.

Using different raw resources is an alternative strategy. One such substance is sodium bicarbonate, which can be used to make glass instead of soda ash. Compared to soda ash, sodium bicarbonate is made using a more environmentally friendly method. Moreover, it can be made from renewable resources, including carbon dioxide that is absorbed during industrial processes.

Read our Books Here: The Complete Book on Glass and Ceramics Technology (2nd Revised Edition)

Creating Glass in a Sustainable Way

In addition to producing soda ash sustainably, glass producers are also making efforts to lessen their negative effects on the environment. Using recycled glass during the manufacturing process is one strategy. Using recycled glass lessens the demand for new raw materials, resulting in decreased energy use and greenhouse gas emissions.

Enhancing the production process's energy efficiency is a different strategy. Insulation and more energy-efficient furnaces can help glass makers use less energy. To lower the quantity of fuel required to create glass, they can also apply process enhancements like oxygen enrichment.

Also, glass producers are looking into innovative methods to lessen their environmental impact. A procedure for producing glass utilising a direct air capture system, for instance, is being developed by Corning, a renowned glass maker. This technology lessens the demand for soda ash by capturing carbon dioxide from the air and using it as a raw material in the manufacturing process.

The Value of Sustainable Glass Production

For the sake of the industry's future and the environment, glass manufacture must be done sustainably. Glass is a strong, adaptable material that may be utilised for a variety of tasks, including packaging and building. Yet, the production of glass can have a considerable negative influence on the environment. Energy is used up quickly throughout the production process, and greenhouse gas emissions are produced as a result. Moreover, the manufacture of soda ash, a crucial component in the creation of glass, raises environmental issues.

The glass business not only has an effect on the environment, but it also has problems with resources. Raw resources like silica aren't always readily available. Although recycling glass might lessen this problem, it is not a perfect solution. To safeguard the industry's future, it is crucial to create sustainable manufacturing methods for glass.

Sustainable manufacturing techniques have positive effects on the economy as well as the environment. Businesses that use sustainable manufacturing techniques can save operating expenses, boost productivity, and enhance their brand reputation. Also, customers are becoming more ecologically aware and are more willing to support businesses that place a high priority on sustainability.

Related Feasibility Study Reports: Glass Manufacturing - Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue

Conclusion

To sustainably produce glass using soda ash is crucial for the glass industry's future as well as the environment. The manufacture of soda ash and the making of glass can have a smaller negative impact on the environment by using renewable energy sources, alternative raw materials, and improved manufacturing techniques. The environmental effect of the sector can be further diminished by recycling glass, increasing energy efficiency, and investigating innovative technologies. Sustainable manufacturing techniques assist businesses economically as well as the environment. The glass sector can guarantee its long-term profitability and contribute to a more sustainable future for the globe by prioritizing sustainability.

Yet, there are still obstacles to be addressed in order to manufacture glass using soda ash sustainably. The expense of implementing sustainable manufacturing techniques is one of the major obstacles. For instance, utilising renewable energy sources can necessitate sizable infrastructure investments in the form of solar or wind power. Similarly, utilising different raw materials can necessitate spending money on new technologies or R&D.

The absence of standards for sustainable manufacturing techniques is another difficulty. Sustainable manufacturing is not universally defined, and many businesses may take different approaches to sustainability. Because of this, it may be challenging for customers to compare the environmental effects of various goods and businesses.

Industry, governments, and consumers must work together to find solutions to these problems. Governments can impose restrictions and incentives to promote environmentally friendly industrial processes, such as tax credits for businesses that employ renewable energy sources or rules requiring environmental impact reports from businesses. Customers can also help by supporting sustainable businesses by buying their goods from them and by calling for increased supply chain transparency.

It is essential to produce glass using soda ash in a sustainable manner if the glass industry is to survive. To lessen its influence on the environment and preserve its long-term existence, the sector must prioritise sustainability. While there are obstacles to be overcome, industry, governments, and consumers working together may advance the transition to a more sustainable future.

Circular economy concepts are one possible way to reduce the negative environmental effects of soda ash production and glass making. By extending the life of materials, the circular economy seeks to reduce waste and increase the value of resources. In the case of glass, this can entail using recycled glass as a raw material and creating products that are simpler to recycle when their useful lives are through.

For instance, one of the biggest glass container producers in the world, Owens-Illinois (OI), has incorporated the ideas of the circular economy into their business practises. By 2025, they intend to use 60% recycled glass in their goods. Additionally, they collaborate with nearby recycling facilities to guarantee that their products are properly recycled and design their glass bottles to be simple to recycle.

Watch other Informative Videos: Ceramics and Glass Technology

Innovation in materials science can also aid in lowering the environmental effect of the production of glass, in addition to the circular economy principles. For instance, scientists are investigating the use of bio-based substances like cellulose or lignin as an alternative to conventional glass raw materials. These materials can be made from renewable resources and are less harmful to the environment than conventional ones.

The technology used in glass manufacture is another area of advancement. New glass production techniques that utilise less energy and emit fewer greenhouse gases are being investigated by researchers. For instance, "flash sintering," a technique created by researchers at the University of Cambridge, uses an electric field to swiftly fuse glass particles together and lowers the energy needed for the manufacturing process.

The production of glass using soda ash responsibly is a difficult task that calls for a diverse strategy. Governments and consumers must support sustainable manufacturing methods, and the industry must emphasize sustainability. Principles of the circular economy, advancements in materials science, and innovative production techniques can all help to lessen the environmental impact of the manufacture of glass. Together, the glass sector can build a more sustainable future while supplying the adaptable material that is necessary for many facets of contemporary life.

Visit the page Select and Choose the Right Business Startup for You for sorting out the questions arising in your mind before starting any business and know which start-up you can plan.

We, at NPCS, endeavor to make business selection a simple and convenient step for any entrepreneur/startup. Our expert team, by capitalizing on its dexterity and decade's long experience in the field, has created a list of profitable ventures for entrepreneurs who wish to diversify or venture. The list so mentioned is updated regularly to give you a regular dose of new emerging opportunities.

Click here to send your queries/Contact Us

Reasons for Buying NIIR Report:

● Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

● Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

● Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

● Our Report provides indispensable buyers' data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

● Our report provides forecasts of key parameters which help to anticipate the industry performance.

● We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

See More Links:

· Start a Business in Asia

· Start a Business in Potential Countries for Doing Business

· Best Industry for Doing Business

· Business Ideas with Low, Medium & High Investment

· Looking for Most Demandable Business Ideas for Startups

· Startup Consulting Services

· Start a Business in Africa

· Start a Business in India

· Start a Business in Middle East

· Related Videos

· Related Books

· Related Projects

· Related Market Research Reports

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬

NIIR PROJECT CONSULTANCY SERVICES, DELHI

An ISO 9001:2015 Company

ENTREPRENEUR INDIA

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: npcs.ei@gmail.com

info@entrepreneurindia.co

Tel: +91-11-23843955, 23845654, 23845886

Mobile: +91-9097075054, 8800733955

Website: https://www.entrepreneurindia.co

https://www.niir.org

OF_20Art23