CASHEW FENI

INTRODUCTION

Cashew Feni unlike Indian Made Foreign Liquor (IMFL) viz., Brandy, Whisky, Rum, Gin etc, is not made by blending of spirits but is distilled exclusively from the pure fermented juice of cashew apples, without addition of any extraneous matter.

It is estimated that about 25 lakhs tonnes of cashew apple fruits are available in the country. Most of the fruits, at present not utilised by the industry in any of the cashew growing tracts in India except Goa where it is used in the preparation of alcoholic beverages 'FENI.' In order to utilise the large quantity of cashew apple being produced by the growers, it is felt that units manufacturing 'Cashew Feni' and 'Cashew Arrack' can be encouraged.

Market Potential

Cashew apple is a rich source of sugar, vitamins and minerals. It is observed that the Vitamin-C content in Cashew apple is five times more than that in citrus fruits. The cashew feni has proved to be a foreign exchange earner in Goa. In view of the above, it is envisaged that there is a good scope for setting up export-oriented liquor making units in cashew and coconut growing areas. This will not only help the farmers to utilise the waste material but also generate more employment opportunities in rural areas. There is a need to encourage the enterpreneurs and look for healthy market for the product.

Present Manufacturers

1. M/s. Dharamvir Exports

A-112, Defence Colony

New Delhi - 110024

Tel: + 91-11-24335242, 51550787

Fax: + 91-11-24332488, 51550787

Email: dvexpo@del3.vsnl.net.in

expo@indikagold.com

Website: http://www.indikagold.com

2. M/s. Indigo Multitrade Pvt. Ltd.

416 & 408, Bhaveshwar Complex

Vidya Vihar (West)

Mumbai - 400086

Tel: + 91-22-25092470, 25092471, 25092472

Fax: + 91-22-25090595

Email: indigotrade@satyam.net.in

indigotrade@gems.vsnl.net.in

Website: http://www.indigomultitrade.com

3. M/s. Miltop Exports

672, GIDC II, Dared

Jamnagar - 361004

Tel: + 91-288-2730228, 2730497, 2730810

Mobile No.: 9824083954

Fax: + 91-288-2730498

Email: mail@miltopexports.com

Website: http://www.miltopexports.com

4. M/s. Pioma Industries

"Rasna House," 8th Floor Panchwati,

Ahmedabad - 380006

Tel: + 91-79-26427774, 26403338, 26566272, 26430789

Fax: + 91-79-26402574

Email: exports@rasnainternational.com

Website: http://www.rasnainternational.com

Implementation Schedule

The major activities in the implementation schedule may be tabulated as below:

| Sl.No. | Activity | Period (Months) |

| 1. |

Selection of site/working shed |

1 |

| 2. |

Preparation of feasibility report |

1 |

| 3. |

Registration with commissioner of industries/ DIC |

2 |

| 4. |

Arrangement of finance (term loan and working capital) |

2-3 |

| 5. |

Procurement of machinery and equipment |

2 |

| 6. |

Installation/Erection of machinery/Test equipment/Commissioning |

3 |

| 7. |

Procurement of raw materials |

1 |

| 8. |

Recruitment of technical personnel etc. |

1 |

| 9. |

Trial production |

2 |

Notes

- Many of the above activities shall be initiated concurrently.

- Procurement of raw material commences from the 7th month onwards.

- In case the imported plant and machinery are required the implementation period of project increases by atleast 2-3 months as procurement of machinery from foreign is a time taking process.

TECHNICAL ASPECTS

Process of Manufacture

Cashew apple after washing is fed into juice extractor. The extracted juice is kept for 2 to 3 days to get it fermented. Fermentation is verified on the basis of formation of a film floating over the juice. From 50 litres of fermented juice, 35 litres of arrack is distilled which contains 40% alcohol. The Feni is obtained by distilling arrack, mixed with fermented juice in ratio of 1 : 2 which is a powerful form of cashew liquor. A mixture of 30 litres of arrack and 60 litres of juice produces 15 litres of Feni which contains 75% of alcohol. To get a litre of arrack, 12 kg to 15 kg cashew apple and for a litre of Feni, 30 to 35 kg cashew apple are required.

Quality Control & Standards

Since the unit proposes to produce alcoholic drinks, licences from both Central and State Governments have to be obtained. The unit may also produce products as per the following I.S.I specifications:

- Brandies - IS : 4450 : 1978

- Country Spirit (Distilled) - IS: 5287 : 1978

- Methods of sampling for alcoholic drinks - IS: 3753 : 1967

- Methods of test for alcoholic drinks - IS : 3752 : 1967

LEATHER TRAVELLING BAG

Introduction

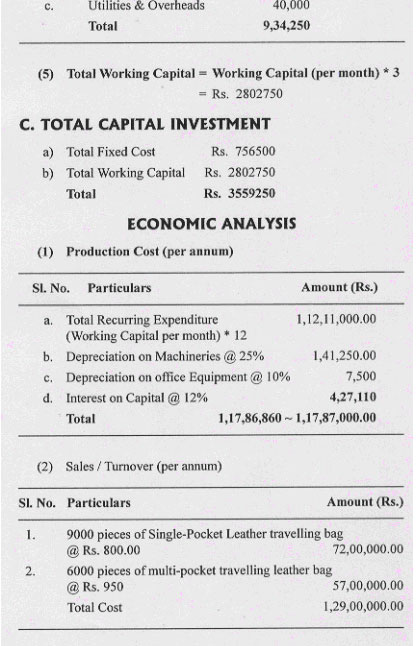

Travelling bag is one of the convenient goods used for carrying the belongings such as clothes, daily-use articles and other essentials during travel. Some other types of products are also used for carrying important documents and office use equipments by the executives and high profile personnel. Although this product is manufactured from various types of materials such as textile, jute, coated fabrics, yet leather travelling bag is having wider acceptance due to its superior strength, aesthetic look and up-man-ship among middle and high-income group people. A wide range of travelling bags are in use for various purposes. The cost of the leather bags depends upon the type of leather, space and/or style of it. This project aims at manufacturing two types of bags i.e.:

- Bags of single large pocket with one or two zips usually made from heavy cow or buffalo leather, and

- Bags of multi pockets with interlining and re-enforcement, flat type, fitted with magnetic press buttons, commonly made from cow nappa leather.

Market Potential

The demand of the leather travelling bag is increasing day-by-day in tune with the growth of industrialization, economic standards of people, tourism and fashion consciousness. The important customers of such products are medium and high-income group people belonging to service, business and executive classes. The proposed poduct with the price of about Rs. 800 to Rs. 1000 is felt quite acceptable with reasonable quality. Further, export worthiness of this product is quite substantial with qualitative and latest design. A small manufacturer can have tie-up with any exporter merchant in the country for executing the order as per the specified design. There is ample scope for leather travelling bag units with easy and considerably cheaper availability of indigenous raw material and skilled manpower.

Present Manufacturers

1. M/s. Superhouse Leathers Ltd.

150 Feet Road, Jajmau

Kanpur - 208 010

P.O. Box 99,

Kanpur, U.P. - 208 010

Tel.: +91-512-2460496, 2461391, 2463373

Fax: +91-512-2460814, 2462124

E-mail: safetyshoe@superhousegroup.com

Website: http://www.superhousegroup.com

2. M/s. Triple Helix Industries,

20-E, Sipcot Industrial Complex,

Sipcot, Ronipet,

N. Arcot - 632 403,

Tel.: + 91-4172-244769, 247491,

Mobile No. 98423 44769, 98941 46889

Fax: No. +91-4172, 247491

E-mail: helix@md5.vsnl.net.in

Website: http://www.triplehelixindustries.com

3. M/s. Nebula Impacts

Building, Rajlaxmi Appt. 39,

C. Khudiram Bose Sarani,

Kolkata - 700 037,

Tel.: +91-33-25280182

Fax: +91-33-24853275

E-mail: nebulaimpacts@vsnl.com

nebulaimpacts@yahoo.com

4. M/s. Raheja Leather Exports,

31/33, Lalwani House,

2nd Floor, Room No. 4,

Mirza Street,

Mumbai - 400 003

Tel.: +91-22-23430663

Mobile No. 98201 30691

Fax: +91-22-23413174

E-mail: rahejaleather@hotmail.com

Website: http://www.rahejaleather.com

5. M/s. P.S. Daima & Sons

RZ-156, Sayed Nangloi,

New Delhi - 110 087

Tel.: +91-11-25252660, 25254281, 25266744

Fax: +91-11-25254282, 25254285

E-mail: psdaima@del3.vsnl.net.in

daimaps@eth.net

Website: http://www.psdaimaandsons.com

Implementation Schedule

The major activities in the implementation schedule may be tabulated as below:

| Sl.No. | Activity | Period (Months) |

| 1. |

Selection of site/working shed |

1 |

| 2. |

Preparation of feasibility report |

1 |

| 3. |

Registration with commissioner of industries/ DIC |

2 |

| 4. |

Arrangement of finance (term loan and working capital) |

2-3 |

| 5. |

Procurement of machinery and equipment |

2 |

| 6. |

Installation/ Erection of machinery/ Test equipment/Commissioning |

3 |

| 7. |

Procurement of raw materials |

1 |

| 8. |

Recruitment of technical personnel etc. |

1 |

| 9. |

Trial production |

2 |

Notes

- Many of the above activities shall be initiated concurrently.

- Procurement of raw material commences from the 7th month onwards.

- In case the imported plant and machinery are required the implementation period of project increases by atleast 2-3 months as procurement of machinery from foreign is a time taking process.

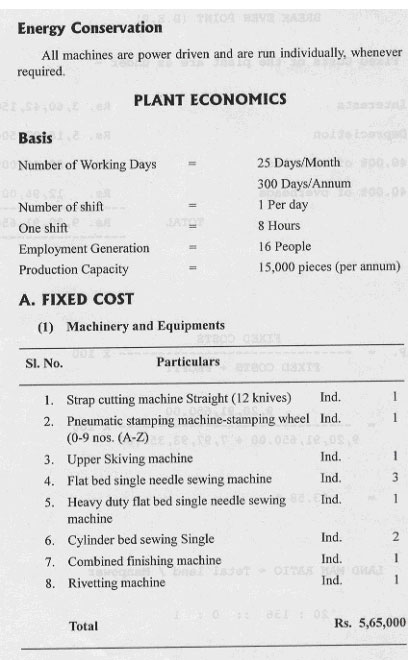

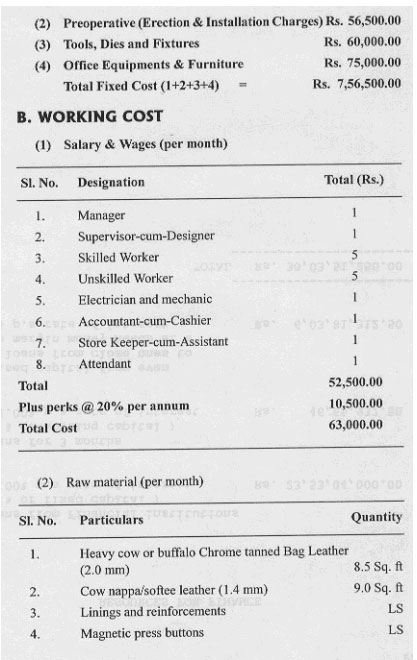

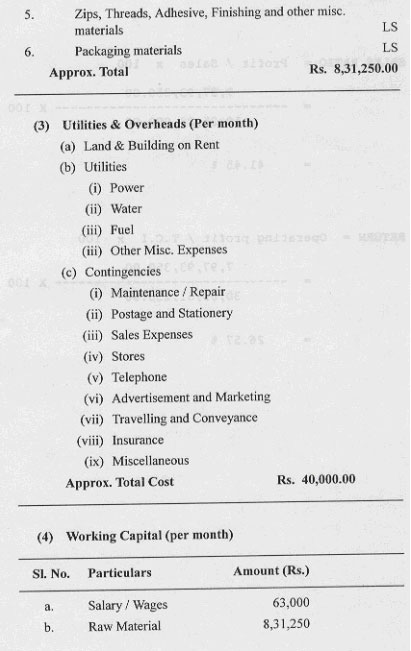

TECHNICAL ASPECTS

Process of Manufacture

The leather travelling bags proposed to be manufactured in this project are mainly of two types. One is of single large pocket with a space of 3 to 6 ft. fitted with one or two fasteners and a long strap handle and other one is of multi-pockets (3 to 5) fitted with different types of fasteners like zips, velcro or press buttons. While heavy cow or buffalo bag leather with the thickness of 2.0 to 2.5 mm without lining is preferred for making the former, the softy type of leather like cow nappa leather with the inter-lining and reinforcement is usually used for the later.

First of all the components are cut from suitable materials. The basic raw material is the finished leather, which is not uniform, irregular in shape and size, variation with grain structure and presence of defects on the surface. On the other hand, the components are generally regular or rectangular shape and the adjacent components should have similar shade and structure. Therefore, necessary care should be taken in cutting the components. The cut components are then skived to the edges for ease of folding and/or stitching. The edges are then beaded and the zips and other fasteners attached as per the specification. The outer surface (leather), the inner surface (lining) and the re-enforcement materials if required so, are attached first with the adhesive and then by stitching. The linings and thread-ends are trimmed and sealed. The surface is cleaned and polished and made ready for packing.

Quality Control and Standards

The quality of this product has to be maintained as per buyer's specification. However, the main criteria for quality control are selection of suitable materials, (especially the leather with required thickness, shade, strength and softness) cutting components from suitable portions of leather, uniform folding, fastener attachment, regular stitching with suitable thread with specified stitch length and finishing.

Motive Power 10 Hp.

Pollution Control

The proposed unit does not produce any effluent. However, the scraps of leather and other materials are to be collected and disposed-off at appropriate place or are burnt at an isolated place.

Energy Conservation

All machines are power driven and are run individually, whenever required.