Rice

Production and Utilization

I. ORIGIN OF RICE

Rice (Oryza sativa L.) is one of the leading food crops of the world, and is produced in all continents. Rice was an important food even before the dawn of written history. One center of origin of cultivated rice is thought to have been in Southeast Asia, that is, in eastern India, Indo-China, and southern China. Another probably was in Africa.

The origin of cultivated rice has been studied by many investigators, and the results of these studies summarized. Most think that the original ancestral species no longer exist and that present varieties have evolved from known species. Most rice varieties currently in production are in the species O. sativa. However, some varieties grown in Africa are in the species O. glaberrima Steud.

The true number of species of the genus Oryza is not known. A large number have been described, but most authorities agree that there are 30 or fewer valid species.

II. COMPARISON OF RICE WITH OTHER CEREAL GRAINS

All of the principal cereal crops are used for food. Rice, wheat, and rye are used primarily as human food. Maize, sorghum, and millet are important foods in some countries but are generally considered to be feed crops. Barley and oats have important uses for human food and beverages but most of the production is used for feed.

The crop area and production of rice in the world are second only to wheat. The world rice crop area is only about 58% as much as that for wheat. However, the average yield of rice is much higher than for wheat, so that the total world production of rice is only about 6% less than for wheat. Over 95% of the world production of rice is used for human food.

Rice is generally considered to be a tropical crop. It is, however, an important crop in subtropical and temperate zones. The yields are higher in temperate areas than in the tropics.

In many Asian countries, the average individual gets half or more of his total caloric intake from rice.

III. COMPOSITION OF RICE AND CEREALS

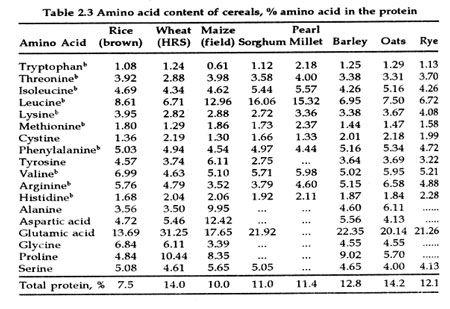

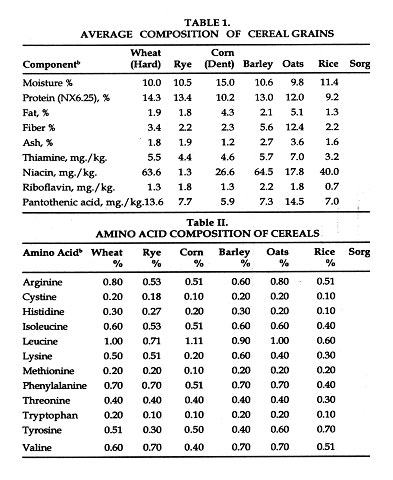

The composition of brown rice; whole-grain wheat, maize sorghum, millet, and rye; lightly pearled barley; and dry oatmeal is shown in Table 2.1. Rice is comparatively high in caloric value, N-free extract, and niacin, and is comparatively low in protein although rice protein has a fairly good balance of the essential amino acids (Table 2.3). The fat content of brown rice is somewhat higher than in

Table 2.1. Average composition of cereal grains.

pearled barley, about the same as in whole-grain wheat, and lower than for other cereals. The fiber content is lower than for other cereals, except for pearled barley. The ash content is slightly higher than for pearled barley, about the same as for corn, and lower than for the other cereals. Brown rice is comparatively low in thiamine and riboflavin.

The composition of rice is influenced by variety and environment. In a study of eight varieties it was found that for the endosperm, ash content ranged from 0.45 to 0.50%; nitrogen, from 1.21 to 1.36%; lipids, from 0.41 to 0.61 %; and starch, from 89.6 to 90.7%, based on the varietal average of material grown at three locations for 3 years. In this same study, the average values at each location for ash ranged from 0.47 to 0.50%; nitrogen, from 1.20 to 1.41%; lipids, from 0.48 to 0.59%; and starch, from 89.3 to 91.0%.

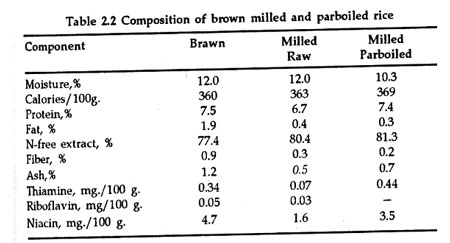

Table 2.2 Composition of brown milled and parboiled rice

The composition of brown, milled raw, and milled parboiled rice is shown in Table 2.2. The principal difference between brown rice and milled raw rice is that the protein; fiber, thiamine, and niacin are higher in brown rice. Parboiled milled rice is similar to brown rice in protein, thiamine, and niacin content.

The amino acid composition of the protein in cereals is shown in Table 2.3. Among cereals, rice has a comparatively high content of essential amino acids and fairly low content of glutamic acid and some other nonessential amino acids. The nutritional level of rice is comparatively high among cereals and other grain and root crops. It was found that rice and rice by-products improved diets based on potatoes, sweet potatoes, corn meal, pinto beans, and cottonseed meal. The favorable amino acid balance of rice is shown by the fact that rice can be supplemented to bring the lysine content to an optimum level at lower cost than for wheat, corn, millet, or sorghum.

IV. BREEDING RICE VARIETIES WITH SPECIFIC PHYSICOCHEMICAL CHARACTERISTICS

Breeding efforts in recent years have been directed toward developing varieties with specific kernel chara-cteristics. Breeding programs have as a major objective the development of varieties that meet specific needs of processors and consumers. The techniques needed to test breeding lines for these characteristics.

Requirements of consumers and processors have been firmly established, so that all new varieties are checked carefully for conformity to the size, shape, and physico-chemical characteristics of the types they represent.

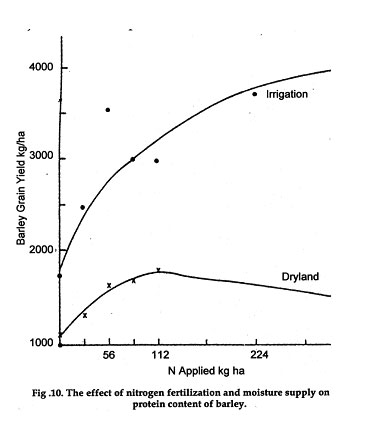

Consideration also is given to developing varieties with improved quality and quantity of grain protein content. There is a wide range in protein content among rice varieties. There also is evidence that protein differences are inherited. The progeny of crosses between varieties that differ in protein content have not been tested for yield, but preliminary observations indicate that it should be possible to develop varieties with higher protein without sacrificing their yielding ability.

Studies of amino acid content show varietal differences. In a comparison of 19 amino acids in 4 varieties, statistically significant differences were shown for 10 of the amino acids. For example, in one comparison the amount of lysine in one variety was only about 78% as high as another variety that was tested. No experimental results are available, however, on the heritability of differences in amino acid level.

V. INDUSTRIAL USES FOR RICE AND RICE BY-PRODUCTS

Rice is a fairly high-cost commodity, which limits its use in industrial products. However, rice-milling by-products have many uses.

Since hulls or husks make up about 20% of the rough rice as it is received at the mill, considerable effort has been made to find uses for them. At one time most of the hulls were used as fuel in the steam plants which provided power for rice mills, but this is no longer a common practice. At the present time hulls are used primarily in feeds, as an adjunct to prevent caking in fertilizers, for mixing with small-seeded forage plants for reseeding ranges, for animal and poultry bedding, and as loose insulating material in walls of buildings and cold-storage facilities. Finely ground hulls also are suitable for use in phenolic resins and in phenol-formaldehyde plywood glues.

Rice hulls are seldom used for production of methyl alcohol, acetic acid, and other products because cheaper sources are available. They are not suitable for making paper or rayon pulps because of their short fibers and relatively low alpha-cellulose content. Rice hulls are a good raw material for the manufacture of furfural but are not widely used for this purpose.

The total by-products of milling are sometimes utilized as "rice mill feed," which usually contains about 61% hulls, 35% bran, and 4% polish.

Rice bran is generally used in animal feeds, and its efficiency as a feed supplement has been widely tested. In one experiment it was found that rice bran can replace up to half the corn in a swine diet before the carcasses were classified as soft pork.

Rice polish, like rice bran, is rich in nutrients. Rice polish is used primarily for stock feed, but some is used in baby foods and health foods.

CARYOPSIS AND COMPOSITION OF RICE

I. INTRODUCTION

Rice grain is relatively less studied than the other major cereal grains: corn, barley, and wheat. In this chapter, emphasis is given to recent publications, since these cite earlier studies.

The rice grain (rough rice) consists of an edible portion, the rice caryopsis, and its covering structures, the hull or husk. The rice hull constitutes from 18 to 28% of the rough-rice weight.

II. GROSS STRUCTURE OF THE RICE CARYOPSIS AND ITS MILLING FRACTIONS

A. Gross Structure

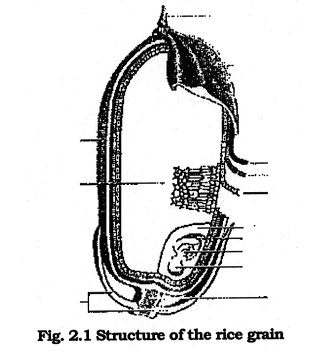

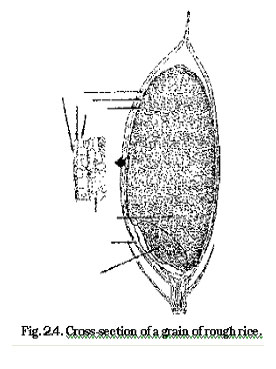

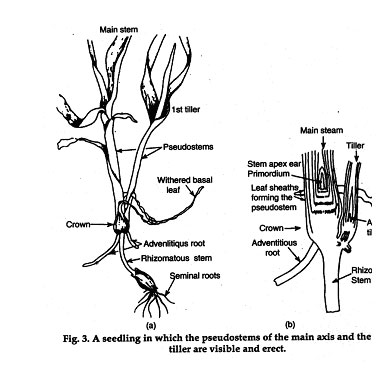

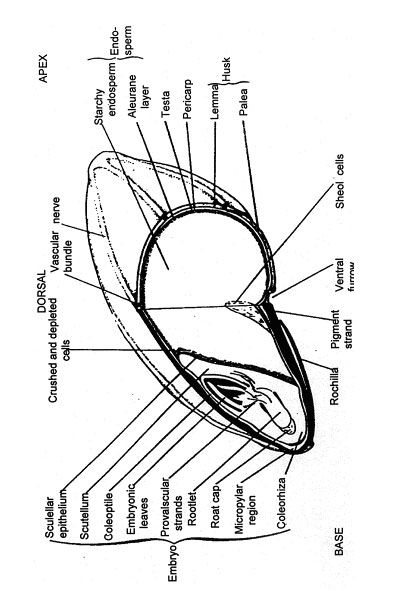

The rice fruit is a caryopsis in which the single seed is fused with the wall of the ripened ovary (pericarp), forming a seed-like grain Fig. 2.1. The caryopsis is called brown rice because of its brownish pericarp. Red rice has a red pericarp or tegmen, or both. The tip of the caryopsis is somewhat oblique, corresponding to the size of the husk lemma, which is larger than the palea. The surface of the caryopsis has ridges corresponding to those of the lemma and palea.

The rice caryopsis varies widely among cultivars in shape and size, length and width. The rice is classified by length into sizes of extra long, more than 7 mm; long, 6.0 to 7.0 mm.; medium or middling, 5.0 to 5.9 mm.; and short, less than 5 mm. (30). The corresponding shape classifications for brown rice based on a length-to-width ratio are: slender, more than 3; medium, 2.4 to 3.0; bold, 2.0 to 2.39; and round, less than 2. Japonica cultivars generally are bold or coarse and short-grain, whereas indica cultivars are usually long- or medium-grain.

The weight distribution of the various parts of brown rice is: pericarp, 1 to 2%; aleurone plus testa, 4 to 6%; germ, 2 to 3%; and endosperm, 89 to 94%. In the germ fraction of brown rice, the weight distribution is epiblast, 0.26%; coleorhiza, 0.18%; plumule, 0.34%; radicle, 0.18%; and scutellum, 1.18 to 1.4% (56). A related study reported pericarp, testa, and aleurone, 6.5%; scutellum, 2.0 and 2.1%; embryo, 0.8 and 1.1%; and endosperm, 90.4 and 90.6%.

B. Pericarp and Tegmen

The caryopsis is enveloped by a fibrous pericarp varying in thickness. The pericarp consists of six layers, five of which are transversely elongated. The pericarp is further classified into outer epicarp, consisting of transversely elongated cells with deeply wavy end walls; hypoderm or mesocarp, also of transversely elongated cells but with straight walls; cross cells of transversely elongated vermiform cells which, except for their transverse arrangement, are quite like the cells of the next layer; and typical tube cells.

Of these layers, the epicarp, with the deeply sinuous end walls and arrangement of cells side by side in rows, is highly characterized in surface view. These cells may be distinct in some varieties but not in others. The cell-walls of the pericarp are 2m thick and absorb stains for protein, hemicellulose, and cellulose.

Next to the pericarp are two layers of cells representing the remains of the inner integuments, the tegmen or seed coat. These layers are denoted as the sepermodern and the perisperm. In surface view the two layers have delicate walls and the cells are side by side in rows, but the elongation is transverse. The perisperm cells are characterized by their beaded walls. The tegmen contains a fatty material.

C. Aleurone Layer

Both the endosperm and the embryo are enclosed by the aleurone, which lies beneath the tegmen. The aleurone may have from one to seven cell layers and is thicker on the dorsal than along the lateral and ventral surfaces. Cultivars differ in the thickness of their aleurone layers. Coarser or bold short grain cultivars tend to have more cell layers than slender long-grain cultivars.

The aleurone layer is composed of quadrangular or rectangular parenchyma cells with thin (2m) wall. These cells are filled with small, protein-rich aleurone grains enclosed in a sheath of fat-staining material. Within the aleurone layer at the dorsal side two or more short layers of polygonal parenchyma cells may occur, also containing aleurone grains. The cell-walls of the aleurone layer react positively to stains for. protein, hemicellulose, and cellulose. Upland cultivars have more aleurone cell layers on the dorsal and ventral sides than lowland cultivars. Warm temperatures during ripening also increase the number of aleurone cell layers, but on the dorsal side only.

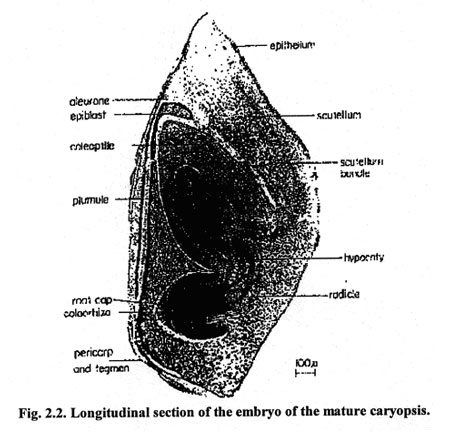

D. Embryo

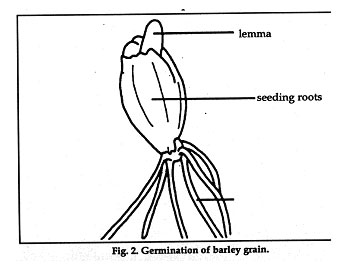

The embryo or germ is extremely small and is located on the ventral side of the caryopsis. In a longitudinal section of the grain, the outline of the embryo appears more or less lenticular Fig. 2.2. It contains the embryonic leaves (plumule) and the embryonic primary root (radicle), which are joined by a very short stem (hypocotyl). The plumule is enclosed by a cylinder-like protective covering, the coleoptile, and the radicle is ensheathed by a mass of soft tissue, the coleorhiza. The embryonic axis is bound on the inner side by the scutellum (cotyledon), which lies next to the endosperm. The embryo is enclosed on the outer side by the aleurone layer. The coleoptile is surrounded by the scutellum and the epiblast, the vascular trace which is fused with the lateral parts of the scutellum.

In a longitudinal section, the plumule and radicle are composed of thin-walled parenchyma cells with square, polygonal, or elongated outline. These are surrounded by epithelial cells, which are also somewhat radially enlongated. The parenchyma cells of the plumule and radicle, together with their epithelial cells, are filled with minute protein granules and fat globules. The outermost layer of the scutellum, toward the endosperm, consists of radially elongated thin-walled parenchyma cells arranged in palisade form and called epithelium. The epithelial cells of the scutellum extend to the base, to the stem, and to the coleorhiza, and are filled with protein granules and oil globules. The scutellum serves as an absorbing and conducting organ for nutrients carried from the endosperm to the embryo during germination. The epiblast, like the scutellum, is composed of thin-walled, rectangular or polygonal cells containing protein and oil particles, and is surrounded by an epithelium.

E. Starchy Endosperm

The starchy endosperm consists of thin-walled pare-nchyma cells, usually radially elongated and heavily loaded with compound starch granules and some protein bodies. The cells toward the flattened or lateral sides are either polygonal or slightly elongated (length to width ratio 0.7 to 1.4); those extended from the ventral to the dorsal side are greatly elongated (ratio 0.2 to 1.0). Generally, the radiating dimensions of these cells are shorter in long-grain cultivars than in medium- or short-grain cultivars. A central, core of small cells has isodiametric shapes ranging in size from about 45 X 50 to 80 X 105m. The length-to-width ratios of these cells in cross-section are approximately 1.0 to 1.2. These dimensions correspond to a cell area of 2,250 to 8,400 m2.

Cultivars may have 12 to 22 cells in the dorsal radius, 10 to 18 cells in the ventral radius, 10 to 17 cells in the lateral radius, and 103 to 256 cells in the longitudinal diameter. The total number of endosperm cells, however, has no proportional relation in general to the length or number of cell layers in the longitudinal diameter, except for cultivars having a very long endosperm. The number of cells is highly correlated to the size (product of longitudinal, dorsiventral, and lateral diameters) of the starchy endosperm but not to its shape (ratio of longitudinal and lateral diameters).

Endosperm cell-walls react positively to stains for protein, hemicellulose, and cellulose. The occurrence of middle lamella and two primary wall layers is suggested in some preparations. The mean thickness of endosperm cell-walls is about 0.25 m.

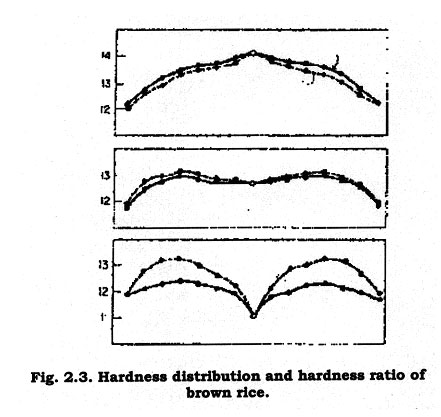

Cultivars differ in hardness distribution in the endosperm. Hardness distribution is represented by hardness values in kg. per mm.2 along the dorsiventral line and the lateral line crossing at the central point on the cross-section of the kernel. Hardness ratio is the ratio of hardness at the middle point of the lateral lines (halfway between the center and the periphery) to that at the central point. Indica cultivars tend to have a hardness ratio of less than l.0 Fig. 2.3. The central core is hardest,

Fig. 2.3. Hardness distribution and hardness ratio of brown rice.

and hardness decreases toward the periphery along lateral and dorsiventral lines. Cells in the central core are isodiametric and arranged radially. Japonica cuitivars tend to have a hardness ratio more than 1.0. In these grains, hardness is greatest at the middle region and becomes less toward the central core and the peripheral region. In addition, the dorsiventral region is softer than the lateral region. In samples with a hardness-ratio of 1.20, the cells of the central core are uneven, markedly flattened, and disorderly arranged. A negative correlation is reported between hardness ratio and length-to-breadth ratio and also in the number of cells on the longitudinal line. The samples with a hardness ratio of more than 1.18 have a loose arrangement of cell contents at the center of the grain. Soft-grain cultivars have higher moisture contents than hard-grain cultivars. The moisture content of their grains also changes faster with a change in relative humidity.

High-protein samples tend to have a more translucent but more tan-colored grain than normal-protein samples of the same cultivar.

Rice starch granules are polygonal and compound. The granule has the structure of a pentagonal dodecahedron and ranges in size from 2 to 10 m. The polyhedral form may be due to compression of the starch granules during grain development. Waxy and nonwaxy starch have similar granule size and shape. The mean total surface area is 7,674 cm.2 per g.

Starch granules are small (2 to 4 m) in the peripheral cells of the starchy endosperm; they are fewest in the lateral and ventral peripheral cells, forming tiny clusters well separated by the surrounding dense protein material. Starch granules of the major, central portion of the kernel are larger (5 to 9 m) and occur in closely packed compound groups, several groups in each cell. Extremely small granules are found in cells near the embryo; they are usually considered devoid of starch. However, the embryo has been reported to contain minute starch granules, the largest ones being in the scutellum.

Few histological studies have been made on the rice starch granule because it is very small compared with that of corn and wheat. An electron micrograph of a hydrochloric acid-corroded rice starch granule shows the layered structure characteristic of an acid-corroded granule.

Up to 95% of endosperm protein has been observed to be in the form of discrete particles called protein bodies. These range in size from 1 to 4 m. Protein bodies are most concentrated in peripheral-lateral and peripheral-dorsal cells (whereas starch granules are fewest and least concentrated in peripheral-dorsal cells) and are found more along the periphery than in the center of each cell. Fat seems to occur in combination with protein bodies. Differences among cuitivars in their distribution in the starchy endosperm have been reported. The protein bodies are about 1m in size at peripheral cells and 2 to 3m in size in the inner cells.

Electron micrographs of isolated protein bodies indicate a layered structure such as is present in the starch granule. These alternating layers of electron-dense and electron-thin proteinaceous materials have not been completely characterized. The protein bodies have a limiting membrane and a fine granulation inside. Some of the protein bodies have a uniformly electron-dense structure which might be an unresolved form of the stratified bodies or may represent another type of protein body.

No phytate-containing bodies (globoids) have been identified in rice endosperm. Hematoxylin-staining bodies, which increase in number during grain development, were termed phosphate bodies because of their positive reaction to molybdate reagent. These are most probably protein bodies.

Opaque or chalky regions appear in the starchy endosperm of nonwaxy cultivars. When the chalky region extends to the center of the endosperm and the edge of the ventral side, this is called a white core. An opaque region occurring in the middle of the ventral side (embryo side) is called white belly or abdominal white. A long white streak on the dorsal side is called the white back.

The opacity was shown to be due to the loose packing of starch granules and protein bodies in this region. In crumbly rice the whole endosperm is practically opaque. Simple and compound granules are loosely arranged throughout the endosperm cross-section. Hematoxylin stains only a minor portion of the space between the starch granules. Hence a major portion of this area in crumbly rice is void space.

Because of the similar chemical analysis of the opaque and translucent portions of the white-belly grain the opaque portions may be structural rather than chemical in nature and probably result from collapse of the protoplasmic gel during endosperm dehydration. These opaque portions are generally softer than the translucent regions and contribute to grain breakage during milling.

Waxy rice cultivars have an opaque endosperm. Histochemical studies show that the starch granules are compound and closely arranged. Presumably the nature of endosperm opacity in the waxy endosperm is not due to the loose arrangement of starch granules. Opacity may be due to the presence in the waxy starch granules of micropores absent in nonwaxy-rice starch granules. This observation is consistent with the lower absolute density of granules of waxy starch (1.480 to 1.496) compared to nonwaxy starch (1.489 to 1.51 1) (36,1 12).

F. Milling Fractions

Abrasive milling removes the outer layers, producing milled or polished rice, and the by-products bran and polish. Bran contains more of the pericarp, tegmen, aleurone layers, and embryo than the polish, which contains relatively more starchy endosperm; and bran has a darker tan color than polish. Usually 10% by weight of brown rice is removed during milling. Bran may vary from 8.8 to 11.5% of the weight of brown rice; polish, from 1 .2 to 2.2%; and milled rice, from 86.0 to 90.0%

Bran and polish consist of fragments derived from the pericarp and tegmen together with a greater portion of the aleurone layer, part of the endosperm, and the embryo. They may be adulterated with hull fragments. Histochemical tests show that they are rich in protein, fat, starch, and free sugars. It was found that a mean bran-polish yield (eight varieties in three locations) of 9.6% from brown rice, of which 1% was endosperm and 8.6% was bran layers plus embryo.

Milled rice is slightly smaller in size than brown rice. Its outer surface is smooth, nonglistening, and waxy white. Each of the flat surfaces has two inconspicuous parallel ridges. The contents of some of the surface endosperm cells are exposed as a result of the removal of the cell-walls. The specific gravity of milled rice ranges between 1.43 and 1.47 at 30°C. and 12% moisture.

When soaked and cooked, milled rice forms transverse cracks as it absorbs water has been described changes in the grain structure on cooking. During cooking some swelling occurs and the pressure of expanding starch causes breaks in the surface of the grain. The extent and pattern of disruption depend on whether the rice is brown or milled, as well as on cultivar. In brown rice a longitudinal fissure commonly occurs along the ventral side. Other forms of kernel disruption in brown rice include splitting of the bran at irregular points around the surface, detachment of the bran, and tendency for the starchy endosperm to slough. Aleurone grains are always birefringent under polarized light in cooked rice, but never in raw rice.

In milled rice, disruption is more complete than in brown rice after a given cooking time. Longitudinal fissures always occur along the dorsal line and usually along the ventral line. The fissures can be shallow. But if they extend from the dorsal side to the core, from the ventral side to the core, or from the dorsal to the ventral side, they split or halve the grain. A simple longitudinal fissuring with a tendency to split is characteristic of long-grain cultivars, whereas splitting accompanied by crosswise segmentation or sloughing occurs in medium- and short-grain cultivars. Starch expansion and tissue splitting are exemplified in the dorsal and ventral cells where sectoring walls are far apart and protein sparse.

Longitudinal fissures in the endosperm involve the rupture of sectoring cell-walls by the expanding starch in affected cells. Halving of the grain is sometimes started by a pre-formed internal rift. Cell separation along a middle lamella is not known to occur.

Some cultivars such as Basmati 370, D25-4, and Iranian varieties elongate greatly on cooking of presoaked grain. The physicochemical nature of this unique property is not well understood. Parboiling also causes some changes in the structure of the endosperm resulting from gelatini-zation of the starch granules, disruption of protein bodies, and a harder grain texture.

G. Changes in Structure during Grain Development

After fertilization, the rice caryopsis develops much faster in the longitudinal than in the transverse axis. The caryopsis attains full length 4 days after flowering, maximum width with the 14-day grain, and maximum thickness with the 21-day sample. Grain weight increases and reaches optimum value in the 28-day sample. Tropical rices are usually harvested 30 days after flowering; in cooler climates, rices may ripen for up to 60 days. This temperature effect on the rate of grain development may explain the divergent results on morphological changes reported by various workers. The consistency of the caryopsis goes through progressive stages termed milky, dough, yellow, and mature.

The morphology of the caryopsis changes rapidly during grain development. The pericarp cells are small when the caryopsis is young but they enlarge as the grain develops later. The innermost epidermal layer, as well as the isodiametric thin-walled cells, becomes compressed and elongated. Cells above these elongated cells toward the outer epidermis fill up with chloroplasts at the dough stage. The innermost cells and those above them become tubular, probably due to compression and rapid elongation, attaining a length about 20 times their diameter. In earlier stages, two or even three layers of such tubular cells are present. But as the caryopsis matures, only the innermost cell layer persists. At maturity all the pericarp cells become greatly stretched, degenerated, and collapsed; nothing remains except their compressed walls.

The outer and inner integuments of the tegmen consist initially of two layers of cells each. The outer integument degenerates and is absent in the 5-day grain. The inner integument elongates and persists during grain develop-ment. At maturity these persistent cells of the inner integument degenerate and collapse. Varieties may differ in the character and behavior of the inner integument, as reflected in the divergent results obtained by different investigators.

The aleurone layer begins to differentiate in the dorsal area 3 days after flowering. In the 4-day grain the aleurone layer cells are nucleated. In the 7-day grain they are already fully developed. The aleurone cells are filled completely with aleurone grains and the nucleus is not always detected. Some simple starch granules may be observed in the aleurone cells of immature grain but they are absent in the mature grain. The aleurone layer is morphologicalJy complete 2 weeks after flowering.

The embryo consists of from 2 to 13 cells during the first 24 hr, after pollination. Differentiation of the coleoptile, coleorhiza, and scutellum begins by the third day. The plumule and the enclosing coleoptile are present in the 5-day grain. The vascular system of the scutellum becomes evident in the 6-day grain. Differentiation of the embryo is complete at least 13 and not more than 20 days after flowering. About 7 days after flowering, the embryo gains the capacity to germinate as a young plant.

The first division of the triple-fusion nucleus occurs 3 to 3.5 hr. after pollination, and nuclear divisions follow at a rate faster than the differentiating embryo. The endosperm has 50 to 80 nuclei by 24 hr. after pollination These form a layer at the periphery of the embryosac. Walls subsequently appear and partition the nuclei into cells. By the fourth day, the embryosac is packed with endosperm cells. Cell division is essentially complete by the tenth day and the approximate aggregate number of endosperm cells is 180,000. The dorsal side develops earlier than the ventral side of the endosperm.

Compound starch granules are first noted in the still-nucleated endosperm cells of the 4-day grain. The compound granule originates from a single amyloplast (24) rather than from several amyloplasts. Starch-granule size increases first and fastest at the center of the endosperm. The compound granules reach maximum size (39 m diameter) by 15 days after flowering. Starch granules in the exterior cell layers increase in size more slowly and are always smaller than those in the interior cells. The starch in the outermost cell layer adjacent to the aleurone layer is the most delayed; the final size of the compound granule is as small as 10m. The size of the granule increases most rapidly during the period 10 and 18 days after flowing. Individual starch granules may increase in mean granule size from 3.3 to 6.3m during grain development. The cell nucleus is difficult to detect in the endosperm cells of the mature caryopsis.

Spaces between the starch granules react positively to stains for protein, but very few protein particles can be distinguished, particularly in the center of the endosperm. Hematoxylin or bromphenol blue stains the distinct protein bodies in the 7-day grain. Hence, starch synthesis must precede protein-body synthesis in the developing rice grain. Protein accumulates from the outer to the inner layer of the endosperm, but starch accumulates in the opposite direction. Very little change in the size of protein bodies can be seen during grain development under a light microscope. Electron micrographs of ripening grain at the milky stage have revealed protein bodies 1 to 3 m in size. In the endo-sperm of the mature grain (of another cultivar), isolated protein bodies range from 1.5 to 4 m. Even at the milky stage, the protein bodies in the cells adjacent to the aleurone layer are smaller (1 m) than those found in the inner cells (2 to 3 m).

Environmental conditions can affect the rate of starch and protein deposition in the developing grain. Based on the progress of endosperm translucency, the completion of ripening is earlier in the central, apical, and ventral portions than in the peripheral, basal, and dorsal portions, respectively. A high temperature during ripening accelerates grain growth and maturation but results in a lower final grain weight of japonica rice. A high temperature (30°C.) increases the ventral radius but shortens the dorsal radius, probably as a result of a vigorous early growth and a slow later growth. Hence the ratio of dorsal-to-ventral radius is a reflection of the ripening process as well as a varietal feature. Grains from plants grown at 30°C. are also softer in the peripheral parts of dorsal and basal regions, suggesting retarded starch accumulation during the later stages of ripening. An opaque portion results from this insufficient filling of endosperm cells. The occurrence of white core is decreased by low night temperature and increased by high night temperature. These grains are somewhat bigger, especially in breadth, than normal kernels, and they also have bigger ventral radii.

Grain development is essentially complete within 3 to 4 weeks after flowering. Endosperm cracks or fissures in rough rice, some researchers claim, result from contact of the dehydrating caryopsis to liquid moisture, such as dew. Cracking results from the sudden contraction of the grain during rapid drying or the sudden expansion of the grain during grain wetting. Waxy cultivars differ in moisture content during drying when endosperm opacity is first observed.

STRUCTURE AND COMPOSITION

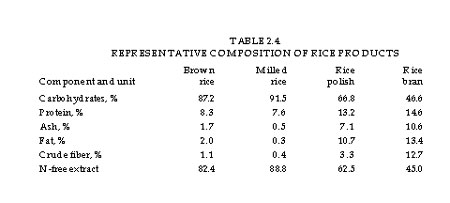

The Composition of typical samples of rice and rice products is shown in Table 2.4. The changes that occur as the grain is milled reflect the uneven distribution of its components relative to the distance from the surface of the kernel. As layers are successively removed, the proportion of protein, fats, and vitamins in the remaining kernel decreases, while the proportion of carbohydrates decreases. Both brown rice and milled rice are common articles of human food, rice polish and rice bran are predominantly used as animal feeds.

Structure of the Rice Kernel

As harvested, rough rice consists of the outer covering tissues comprising the hull, or husk, and the inner kernel, i.e., the caryopsis, or brown rice. The caryopsis is enveloped by the caryopsis coat consisting of the pericarp, seed coat, and nucellar layers. The fibrous pericarp consists of compressed cells and is about ten microns thick. Just inside it is the seed coat, a layer of cells having a thick cuticle and representing what remains of the inner integument. Proceding inwardly, the next layer, only about 2.5 microns thick, consists of the remains of the nucellus; it has a thick cuticle adjacent to the seed coat cuticle. Inside the nucellus layer is the aleurone, which completely encloses the endosperm and the embryo. It is composed of 1 to 7 layers of rectangular parenchyma cells and varies in thickness in different parts of the caryopsis. The structure of a typical rice kernel is shown in the drawing reproduced here as Fig. 2.4. Bran Institute).

Fig. 2.4. Cross-section of a grain of rough rice.

The aleurone cells that surround the endosperm are filled with protein-rich aleurone grains with a single membrane containing globoids or phytate bodies in a protein-carbohydrate matrix, and lipid droplets or spherosomes around a nucleus that is centrally located. Aleurone cells that surround the embryo are modified, lacking aleurone grains, and having fewer spherosomes than other aleurone cells. They also contain filament bundles.

The embryo or germ is relatively small and is located on the ventral side of the caryopsis. Within the germ are embryonic leaves and an embryÂonic primary root joined together by a very short stem. The embryo is bound to the endosperm by the scutellum (cotyledon). Immature cells of scutellum and mesocotyl are found between differentiated parenchyma cells.

The endosperm, which in the mature caryopsis is much larger than all the other tissues combined, consists of thin-walled, radially-elongated parenchyma cells, which are packed with compound starch granules and protein bodies. Protein bodies, which are covered by single membranes, are more abundant in the outer cell layers where the compound starch granules are small. The compound starch granules are in double-membraned amyloplasts. The husk constitutes perhaps 18 to 28% of rough rice, while the remaining 72 to 82% is brown rice. The weight distribution of the brown rice grain components is pericarp 1 to 2%, nucellus and seed coat 4 to 6%, embryo 2 to 3%, and endosperm 89 to 94%. About 6 to 10% of brown rice is removed in abrasive milling, the by-products being bran and polish.

Important Components

Proteins.- The nutritional quality of rice protein is high relative to that of most other cereal proteins. This is due to rice's relatively high content of lysina, which is the first limiting amino acid. Most of the so-called storage proteins in rice kernels are found in discrete protein-rich bodies (aleurins) in the endosperm, similar to the situation in many other seeds. This protein is largely insoluble in water. Most of it- 80% or more in milled rice- is the type called glutelin, soluble only in dilute acids or alkalies. The second most abundant type of protein is the salt-soluble globulin. Both globulins and glutelins are composed of an unknown number of molecular species which are generally isoelectric around pH 7.

The amount of protein and the amino acid composition of the protein of rice will vary with growing conditions and variety. It has been found that the same variety of rice grown at different locations will vary considerably in amino acid composition. As the percentage of nitrogen increases in the grain, due to growing conditions for example, there is a tendency for the percentage of lysine in the protein to decrease. Different rice varieties grown at the same location will also contain proteins varying in amino acid composition. Furthermore, the distribution of the different amino acids is not uniform within the grain. Milling not only causes a decrease in the total protein of the kernel, but also a change in the amino acid pattern of the remaining protein. Generally, the decrease of lysine on milling is disproportionately large, while there is a relative increase of isoleucine, leucine and valine.

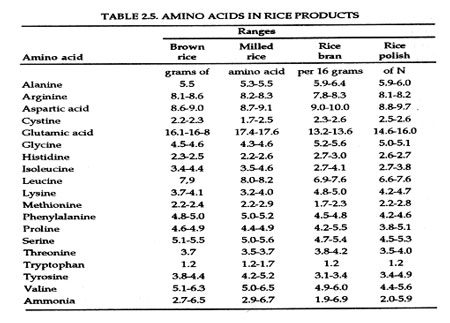

Table 2.5 gives values for ranges in the amino acid composition of brown rice, milled rice, rice bran, and rice polish, as found by one investigator (adapted from Juliano 1980).

Starch.-Milled rice will contain from about 84 to over 90% starch (dry basis). This component is present in the form of angular granules measuring about 2 to 7 microns in their largest dimension. Many of these particles are roughly pentagonal in outline. In size and shape, they are somewhat like the granules of oat starch, but differ in that few if any rounded particles occur. The hilum is centric and indistinct, and birefringence is weak.

In the seed, starch exists in compound granules containing up to about 150 of the smaller particles. These clusters are firmly bound together by a water-insoluble protein matrix which can be dispersed, and the granules released, by various alkaline steeping methods.

The viscosity behavior is similar to that of corn starch. Nonwaxy starch from indica rice contains 21 to 33% amylose, while that from japonica rice will contain a lower amount (17 to 19%) of the linear fraction.

There is a wide variation in iodine affinity and viscometric molecular weight depending on the variety from which the amylose is taken.

Rice starch preparations contain small amounts of lipid. Fats determined by acid hydrolysis amount to about 0.7 to 0.8%. A large part of this material consists of fatty acids which cannot be removed by petroleum ether but dissolve readily in methanol or 80% dioxane.

Waxy (glutinous) rice has been grown in Asia for many centuries. In some countries, the major portion of the crop consists of these varieties. The principal differences between waxy rice and normal rice depend upon the starch,-that from waxy rice consisting of almost 100% amylopectin and thus staining red with iodine solution, while non-waxy starch contains a substantial amount of amylose, and stains blue with iodine. Typically, waxy rice will" contain 2% or less of amylose. Both the flour and the purified starch from waxy rice has been found to have advantages for certain food and indus-trial uses. Gravies, sauces, and puddings based on this starch are very resistant to syneresis during freezing and thawing.

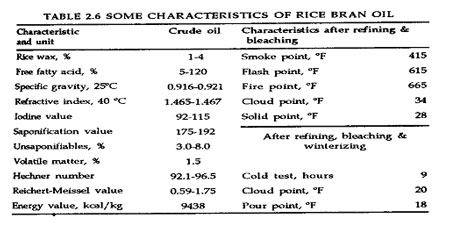

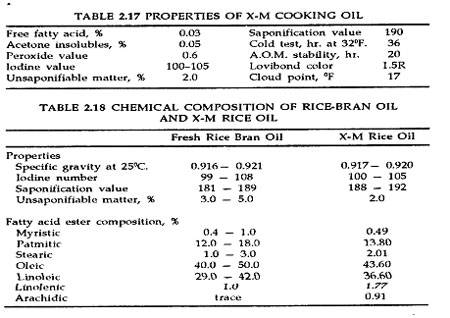

Lipids.-There is very little lipid material in milled rice, perhaps 0.3 to 0.4% by acid hydrolysis could be considered average. Rice bran contains a much higher percentage of lipids, perhaps 21%. Nearly all the studies of rice lipids have concentrated on rice bran oil, and there is a subs-tantial trade in the fatty materials extracted from rice bran and refined.

The glycerides of rice bran oil contain mostly fatty acids having even numbers of carbon atoms from 14 to 20 as well as the odd-numbered fatty acids of chain length 11, 13, and 15. The odd-numbered chains were present in the small amounts of 0.2, 0.6, and 0.9%, respectively, in one sample. Gas-liquid chromotography indicates that bran lipids have significantly higher mean contents of linoleic and linolenic acids, but-lower contents of myristic, palmitic, palmitoleic, and stearic acids, than the lipids of milled rice. The iodine values of bran lipids were reported to be significantly higher than for milled rice lipids, and the lipids of indica varieties had lower iodine values than did this component in japonica rice.

Vitamins.-So far as vitamins are concerned, rice is an important source of only thiamin and niacin. The following data are mg per 100 g, first figure for raw, second for parboiled rice. Thiamin was present at levels of 0.13 and 0.15, niacin at levels of 1.54 and 3.2, pyridoxine at a level of 0.14 for raw, and riboflavin at levels of 0.04 and 0.044. "When compared on an energy basis with the RDA for adult women and when rice is a large part of the diet (2000 Kcal), brown rice would give more than sufficient niacin, thiamin, and phosphorus... Protein needs would be nearly enough- 91%. . .but calcium and riboflavin needs would be low, both about 23% [zinc about 60%]. Milled rice, however, would be deficient in all nutrients with only protein, niacin, and phosphorus supplying more than 50% of the RDA." A more complete survey of reported values of vitamins in rice and rice components is given in Table 2.7. This table is with only the medians of the ranges being taken from the original data.

*Values calculated as mg per kg, 14% moisture basis, except * micrograms per kg.

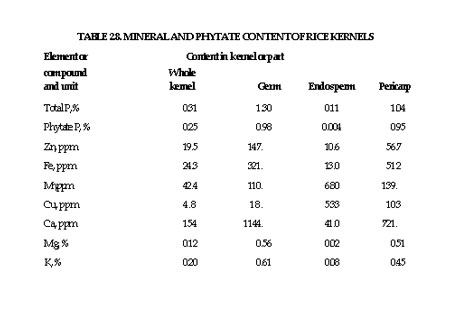

Minerals.-Milled rice is not an important source of minerals by any reasonable standard. The content of ash in a large series of samples ranged from 0.26 to 1.95%, dry basis, with a mean of about 0.65%. There is a considerably higher concentration of minerals in the bran, but the availability of at least some of these is adversely affected by the high concentration of phytin in the bran. Table 2.8 summarizes the mineral and phytate content of rice kernels.

Calcium, iron, potassium, sodium, silicon, magnesium, sulfur phosphorus, and minor amounts of other elements have been found in rice-ash. Potassium and phosphorus are the most abundant mineral elements in rice. Represen-tative figures would be 88 mg and 140 per 100 g dry weight respectively. Appreciable amounts of silicon are found in the mature rice plant, and slight amounts in milled rice; the function of this element in the plant and its value, if any, in human nutrition is unknown.

Sodium, magnesium, and calcium were found at mean concentrations of 8.1, 28, and 25 mg, respectively, in the whole kernels of six varieties of milled rice.

Of the trace minerals, iron is present in brown rice and white rice at 1.8 and 0.9 mg per 100 g, dry weight basis, respectively, and zinc is present at 1.6 and 1.4 mg per 100 g, as is basis, respectively.

Other Constituents.-Sugars, hemicellulose, nucleic acids, pigments, phytin, and numerous other substances have been found in small amounts in rice. Phytin, the principle phosphorus compound in rice is said to constitute more than 8% of the bran in some samples.

There is a small, but important, amount of sugar in rice. Brown rice will contain about 0.8 to 1.4% total sugars. Reducing sugars are typically near 0.1%. Parboiled rice can be expected to contain around 0.7 to 1.1% total sugars, and about 0.16% reducing sugars. Milled rice will typically contain much lower amounts of total sugars, about 0.4%, and perhaps 0.06% reducing sugars.

The amount of fiber found in rice varies greatly, depending on the method of analysis, the variety of rice and its growth conditions, the processing which has been applied to the rice, and other factors. Among the reported values for fiber in brown, milled, and parboiled rices are 0.9, 0.3, and 0.2%, respectively.

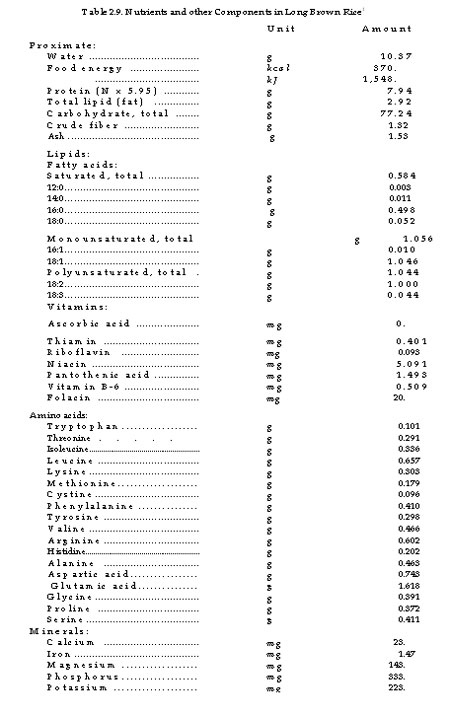

A concise summary of nutrients and other components to be found in a typical sample of long grain brown rice is included in Table 2.9.

1Where no values are stated for a component, or component has been omitted from the listing, there are inadequate data available.

CRITERIA OF RICE QUALITY

I. INTRODUCTION

Rice quality, like that of numerous other food products usually evaluated according to its suitability for a specific end-use for a particular consumer. The quality of rice is closely related to the quality of its milled whole kernels, since essentially all of the domestic rice crop is milled to a high degree. Virtually all rice, in one or more of its many prepared forms, is used as food for human consumption. Some of the most important uses and processing applications of rice include boiled or steamed rice (milled raw rice, milled parboiled rice, brown rice, and quick-cooking rice) for consumer use, prepared in the home, institution, or restaurant; dry breakfast and baby-food cereals; brewers' rice, used as a carbohydrate source in the manufacturing of beer; canned rice, such as in soups, puddings, and mixes; quick-cooking and other convenience and specialty food products; rice flour, as a thickener in sauces, gravies, and puddings; rice starch, for industrial and other processes; and preparations for certain types of fermented foods. Because of its many diverse applications, rice that is satisfactory for one use may not be suitable for other uses. Quality testing, therefore, is primarily a matter of determining whether the rice is suitable for a particular use and whether it meets specific requirements of cleanliness and purity.

Some standards for rice quality are observed in all countries, although in some the requirements are simply that the grain be clean and dry. In a few countries, legislative measures have been taken to prescribe well-defined grades but, despite numerous attempts at establishing uniform standards, there is still no generally accepted basis for trading rice throughout much of the rice-growing world. The most international trade is conducted on the basis of quality as determined generally by visual examination. In most of the local markets of the world there are no fixed scales of allowances for impurities and other defects. A general increase in trade between countries has emphasized the need for establishing universal grades and standards, but little progress has been made.

Consumer acceptance and preference, with respect to eating, cooking, and processing qualities, are important in judging rice, since they vary from country to country and from region to region consumers prefer rice grain that cooks dry and fluffy, with kernels that retain their conformation and remain separate after cooking. Others prefer rice that cooks moist and chewy, with the grains tending to cling together. Since different cultural groups prefer various cooked textures, there is a demand for all types in domestic and foreign trade. Processors of rice also require different textural qualities for use in various kinds of prepared rice and rice-containing convenience-food products. In some processes the dry and fluffy-cooking types are preferred, while in other products, the moist and chewy-cooking types are required. In other countries, the preference range is from waxy or glutinous to a high degree of fluffiness.

Milling yields are based on the amount of whole milled kernels (usually the milled product of greatest value) and all sizes of broken kernels obtainable from a unit of rough rice. Many factors influence milling yield; and the rice processor, usually the miller, must also judge the quality of rice for milling on the basis of variety, moisture content, the presence of red rice, peckiness and other kernel damage,- foreign seeds and other material, chalky kernels, and mustiness or other undesirable odors.

Wide inherent plant differences existing in rice quality are due in part to natural evolution. In more recent years, specific differences have appeared as a result of planned breeding. Marked differences in rice quality also exist owing to environmental and cultural practices during growth. In some instances, differences due to these factors are greater than inherent factors.

Factors influencing rice quality which are independent of inherent, cultural, and environmental differences include those associated with handling, storage, and the incidence of foreign material. For example, rice that has been stored for long periods, or stored under unfavorable conditions for shorter periods, may result in lower yields of processed products and contain varying degrees of objectionable odors and flavors which would decrease its suitability for human consumption. However, a short period of maturation after harvest, under proper storage conditions, is considered desirable by most users to allow important changes in enzy-matic activity to occur.

Thus, rice quality is considered to have two general meanings: 1) milling, cooking, and processing qualities, which refer to suitability of the grain for a particular end-use; and 2) physical quality, which means cleanliness, soundness, and freedom from foreign material. Usually physical quality and milling, cooking, and processing qualities are interrelated in that certain market grades of rice are more suitable than others for consumer products.

The nutritional quality of rice is, of course, of para-mount importance and concerns all aspects of rice quality. However, it is not the purpose of this chapter to present it here.

The scope of this chapter is: 1) to define the more important criteria used in evaluating rice milling, cooking, and processing qualities; 2) to explain how the criteria are effectively used in determining and predicting quality; 3) to describe some of the procedures and instruments used in such determinations; and 4) to present the criteria used in determining the grade of a unit of rice.

II. OBJECTIVE VERSUS SUBJECTIVE MEASUREMENTS OF CRITERIA

An ever-increasing trade, domestically and between markets of the world, emphasizes the need for uniformly accurate procedures for judging rice quality. Unless the procedures are objective, the criteria of quality that can be accurately and uniformly measured and interpreted are difficult to describe. Although many objective methods are available for evaluating rice quality, some important criteria must still be determined subjectively. For several factors, such as odor, flavor, taste, and texture (mouth appeal), no practical objective method or instrument exists. Other factors, such as color, can be measured objectively, but the instruments required are expensive or do not have the ability to adjust for other factors, such as damaged kernels, which influence color. The human eye has the capability of making this adjustment; however, because of the vast differences in sensitivity of individual eyes and human errors in judgment, reproducibility of results is very poor. The authors of this chapter have attempted to cite objective methods, or instruments for making objective measurements, whenever these are practical or appropriate. Progress is being made in developing new tests and instruments, but much more research is needed. Therefore, rice buyers, processors, inspectors, and researchers currently must rely on subjective measurements of several quality factors.

III. VARIETIES

Rice varieties (Oryza saliva L.) are divided by grain size and shape into three types, known as short-, medium-, and long-grain rice. Historically, and now through planned breeding, each grain type is associated with specific milling, cooking, and processing characteristics. Raw milled rice of typical long-grain varieties usually cook dry and fluffy when boiled or steamed, and are generally preferred for use in prepared products, such as parboiled rice, quick-cooking rice, canned rice., canned soups, dry soup mixes, frozen dishes, and other convenience-type rice-containing foods. Typical short- and medium-grain types, on the other hand, cook moist and chewy, and are preferred for manufacturing into such products as dry breakfast cereals or baby foods, and for brewing uses. Therefore, since domestic and world trade associates long-, medium-, and short-grain varieties with specific milling, cooking, and processing characteristics, it is essential for new varieties of each grain type to have the same (or improved) qualities as the varieties they replace.

There are a number of rice varieties of each grain type in commercial production, and new ones are continually in the process of being developed and released. Previously, in rice-breeding programs, most emphasis was placed on grain yield, grain type and appearance, milling yield, plant type, nitrogen responsiveness, and resistance to diseases and insects. Now, particular attention is being paid to the cooking and processing qualities of rice for specific uses.

With but few exceptions, the grains of all rice varieties in commercial production are described as translucent, non-scented, nonwaxy (common) types which contain varying ratios of amylose and amylopectin starch, and are considered by the trade as being bland in taste. One exception is a limited production of waxy (glutinous) rice. This rice, also called "sweet rice", is characterized by an opaque 'endosperm containing virtually all amylopectin-type starch. Waxy rice is produced primarily for specialty products and for certain ethnic-group uses. Another exception is the scented (aromatic) rice produced on small acreages as a specialty product. This rice gives off a popcorn-like aroma during cooking, and has a flavorful and appetizing taste similar to the much-sought-after "Basmati" class of varieties in India. Its grain is also described as translucent and contains both amylose- and amylopectin-type starch.

IV. GRAIN SIZE, SHAPE, WEIGHT, AND UNIFORMITY

The physical dimensions of rice kernels are of vital interest to those engaged in the many facets of the rice industry. These dimensions are important in marketing and grading, in developing new rice varieties, in cleaning and grading equipment, in drying operations, and in processing.

Rice is marketed under three market types, designated as long-grain, medium-grain, and short-grain. Varieties of each grain type must conform within rather narrow limits to the size and shape specifications established for that type. Thus, grain size and shape are among the first criteria of rice quality that breeders consider in developing new varieties for release in commercial production. If the variety does not conform to recognized standards for grain size, shape, weight, and uniformity, it is simply not considered for release. In early developmental stages, close visual examination of the grain is made to ascertain that its configuration conforms to that of other commercially acceptable varieties of the same grain type. Inherent grain defects, such as irreguilarly shaped grains, sharp pointed extremities, oversized germs, and deep creases which cause bran streaks in milled rice, must also be eliminated in early developmental work, as these defects reduce the milling yields of rice and detract from the general appearance of the processed product.

While grain type can be visually classified, more exact measurements are needed for classification and for critical comparison of varieties. Rice grains may be objectively classified into grain-type categories based upon three physical quantities: length, shape, and weight. Length is simply a measure of the rough-, brown-, or milled-rice kernel in its greatest dimension. The shape is determined by a ratio of two of the three dimensions - length, width, and thickness. Probably the most meaningful of these is the length:width ratio, since it is used in sizing rice with slotted sieves or so-called precision graders. Finally, the grain weight (size) is determined by taking the mean of the weight of a 1,000-kernel representative sample. Uniformity of grain size and shape is calculated by determining the coefficient of variation for each dimension of a representative sample.

Some attempt has been made to subdivide the types into finer gradations, such as long-slender and medium-slender. However, these distinctions may not be justified, since there is considerable overlap between long and long-slender and between medium and medium-slender types.

The weight of rice kernels can vary considerably with moisture content, type of soil where grown, fertilizer treatment, and weather conditions. Consequently, a better or complementary measurement may be that of density. A device known as an air comparison pycnometer, which permits rapid density measurements of granular materials, is now commercially available.

V. COLOR AND TRANSLUCENCE

The color is used as a criterion of quality for all forms of rice. The evaluation, however, is generally performed on whole-kernel rice after it has been well milled. Colors of raw milled rice range from white to dark gray or rosy. Rosy color occurs when rice is milled with a large quantity of red rice. The bran from the red rice stains the endosperm of the cultivated variety. Parboiled rice is usually .graded from "parboiled light" to "parboiled dark", depending upon the degree of coloration resulting from the parboiling treatment. The trend in commercial processing is toward "parboiled light", which is accomplished through various parboiling techniques and bleaching processes.

Color of raw milled rice is often referred to as general appearance. The latter term is probably more descriptive, since it takes into account not only the hue, lightness, and saturation, but also various defects which contribute to the tristimulus factors of color. For example, smut may contribute toward a distinct gray tint, whereas heat damage may contribute toward a particular hue. General appearance, as a quality factor, can be determined only by a visual examination, since it is composed of many different factors which the human eye can integrate into one hypothetical, but nevertheless useful, value.

Color may also be an indication for other quality criteria. For example, the International Rice Research Institute showed that high-protein rice was less white (more tan-colored) when cooked than rice with normal protein content. In the quality-evaluation studies color ("L" value for lightness) "was negatively correlated with surface lipids-in all grain lengths-and positively correlated with water uptake and sediment." However, the study also recognizes that surface lipid content and color are partly dependent upon the degree of milling, which may also affect the water absorption of rice.

Several attempts have been made to use optical instruments for measuring the color and degree of milling of rice. It is shown that optical-transmission measurements are generally unsatisfactory for color measurements. Reflectance measurements, however, are quite reliable for measuring color. A color and color-difference meter equipped with a large-angle viewing head, such as the Hunterlab Model D25, is probably one of the most suitable commercially available instruments. The tristimulus color factor known as "lightness" (Hunter L) correlated highest (r=0.946) with visual color as determined by official rice inspectors visual deter-minations. Other simple reflectance meters, are now commercially available. The use of one or more of these instruments would probably satisfy the needs of an objective method of measuring the color of rice.

Another quality factor closely related to color is that of translucence. Nonwaxy (common) varieties of rice have a vitreous, translucent endosperm of varying degrees of apparent hardness. This trait is highly desired by the rice industry, and rice breeders pay particular attention to developing new varieties having bright, clear, highly translucent milled kernels free of inherent chalky spots. In the vitreous types, chalky grains also occur when rice is harvested too early and some kernels are not mature, and when the rice is grown under environmental and cultural conditions conducive to chalk formation. Translucency in rice is usually subjectively determined by close visual examination of the well-milled kernel. In contrast to the vitreous translucent types, another kind of rice known as glutinous, sweet, or waxy rice is characterized by a completely opaque endosperm.

VI. TEST WEIGHT

Closely related to the criterion of kernel weight is another factor called the test weight per unit volume. It is directly related to the bulk-density of the grain. Test weight is useful as an index to milling outturn, in measuring the relative amount of dockage or foreign material in a given lot of rice, in measuring the amount of shriveled or immature kernels, and in estimating the weight contained in a storage bin of given volume. In countries using the metric system, the test weight is expressed in terms of kilograms per hectoliter. Multiplication factors for converting test weight from any one of the commonly used systems to any other are given below.

I

| From | To | Multiply by Factor |

| b./Winchester bu. |

Ib./Imperial bu. |

1.032 |

| Ib./Imperial bu. |

Ib./Winchester. bu. |

0.969 |

| Ib./Winchester bu. |

Kg./hectoliter. |

1.287 |

| Kg./hectoliter. |

Ib./Winchester.bu. |

0.777 |

| Ib./Imperial bu. |

Kg./hectoliter |

1.247 |

| Kg./hectoliter |

Ib./Imperial bu. |

0.802 |

VII. MOISTURE CONTENT

Moisture content has a marked influence on several facets of rice quality. Its effect is of primary importance on the keeping properties of rice during storage, because under practical storage conditions moisture level is usually the factor most responsible for controlling the rate of deterioration of the grain. Only a few days are required for wet rice to deteriorate badly, whereas dry rice can be kept for relatively long periods when properly stored. Moisture contents commonly accepted for "safe" storage of rough rice are 13% for less than 6 months, and 12% for long-term storage.

Milling quality is greatly influenced by moisture content of the rice at harvest time, during drying and storage, and while milling to prevent excessive breakage. To command premiums, rice must be of high milling quality, and for this high quality it must be harvested at the correct stage of maturity, and properly dried, stored, and milled under moisture conditions optimum for minimum breakage.

It show that how moisture content of grain can be of direct economic importance based on the amount of water contained in a carload of wheat of 14% moisture versus 8% moisture content. This relation could apply to rice as well as other grain; but because of the precautions taken in producing, harvesting, and artificially drying domestic rice, fluctuations in moisture content are not usually as great as for some other grains.

Other quality factors, associated with rice milling, cooking, and processing characteristics, may be adversely affected by excessive moisture. During storage these characters usually change more rapidly in high- than in low-moisture rice. Also, uniformity of grain moisture content (individual kernels), as well as limitations on moisture level, is a primary consideration for rice to be used in dry breakfast cereals, parboiling, and other processed rice and rice-containing foods.

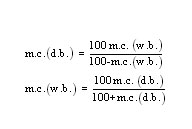

Several methods are available for determining the moisture content of rice. The basic method used is 130ºC. 1 hr. air oven method. Another basic method used frequently is the vacuum-oven method for cereals. The principal disadvantage of these conventional methods is the relatively long time required to run the test. Where rapid results are necessary- such as in driers, mills, and for grading purposes-the electric moisture meters are widely used and, under controlled conditions, are sufficiently accurate for most control work. For the most satisfactory results, these instruments must be calibrated with one or more of the conventional methods

VIII. IMPURITIES AND DAMAGED RICE

The quantity and character of impurities and damaged kernels in rice obviously affect the value of a lot. In addition to reducing the quantity of usable rice, lowering milling yields, and affecting the value of rice for food, certain impurities can also damage the processing equipment. For example, stones can severely damage rubber-roll shellers.

A. Dockage

Dockage is defined as all matter other than rice which can be removed readily from the rough rice by the use of appropriate sieves and cleaning devices. This includes underdeveloped and shriveled kernels as well as small pieces of rough rice which are removed in proper separation of the dockage and which cannot be recovered by proper rescreening or recleaning. Other impurities which may be difficult to remove because they have approximately the same size, shape, and density as rice are classified as objectionable materials. Certain weed seeds, and metal and glass fragments fall into this category.

Generally, brown and milled rice are sufficiently clean to make the dockage test unwarranted.

B. Damaged Kernels

Damaged kernels are defined as kernels and pieces of kernels of rice which are distinctly discolored or damaged by water, insects, heat, or any other means. When parboiled-rice kernels are found in nonparboiled rice, they are classified as damaged rice. Whole kernels of parboiled rice found in nonparboiled rice, which are as dark as, or darker in color than, the interpretive line samples for heat-damaged kernels are classified as heat-damaged rice. This distinction is made because heat-damaged rice is considered to be a more serious defect than some other forms of damage.

Damage to rice can occur in the field prior to harves-ting, during drying operations, or during subsequent storage and handling. Wet weather, after the rice has matured, can cause various types of staining, and promote the growth of fungi. Excessive heating from either artificial drying or high-moisture conditions in storage can result in the development of red to brown stains known as heat-damaged kernels. Certain types of storage fungi can also produce this type of discoloration. Damage may also result from insect infestations, which can seriously reduce the quality of rice for human consumption. Finally, mechanical damage can result in lowering the yield of both total and whole-kernel milled rice, because of breakage of the endosperm or weakening of the kernel by fissures.

The only reliable method presently available for determining the amount of damaged kernels in rice is visual inspection. The rice inspector must be trained to recognize various types of damage that may occur in rice and he must be able to judge in each instance whether the damage is sufficient to be considered under the applicable standards. This often involves hand picking, separation, and counting. Electronic seed counters are now available to assist in the counting operation, but the entire process remains slow and tedious.

Various color sorters have been manufactured to separate particles of a distinctively different hue from particles of another hue. However, these devices are not satisfactory for grading for two reasons: 1) since all commercial sorters use reflected light, they fail to detect particles only slightly different in hue or particles that are opaque, and 2) all commercial color sorters are production-type machines which sacrifice accuracy for high volume. However, research and grading laboratories must now rely on visual examination to detect and evaluate damaged kernels in rice.

Some of the commercial electronic color sorters are in use in rice mills, primarily for separating peck (discolored) kernels from normal kernels in parboiled rice. Parboilers of rice usually consider any distinctly discolored kernel, regardless of source of discoloration, as pecky rice. Peck in parboiled rice is a severe problem, since the parboiling process tends to intensify color development in the damaged kernels and most of these kernels must be removed before use. Some parboilers set their own requirements as to the amount of peck which can be tolerated in rice purchased for parboiling. Usually this tolerance is very low (1.5% and less) because of the difficulty and expense incurred in removing pecky kernels from the parboiled product.

C. Chalky Grains

Chalky grains, as mentioned previously, occur under unfavorable environmental and cultural conditions and when rice is harvested too early and includes immature kernels. In some varieties the panicles do not mature uniformly, so that some kernels are immature while others are overripe; in certain varieties there is a genetic tendency for chalkiness in all kernels. Chalky rice not only detracts from general appearance, but is usually very weak and, therefore, breaks up easily during milling, with a subsequent reduction in the yield of milled rice. An exception to this occurs when rice -is parboiled, since the gelatinization process tends to strengthen the kernels. However, excessive chalkiness, even in rice to be parboiled, may not be desirable for modern parboiling processes because of the possibility of product nonuniformity as a result of overprocessing some kernels while underprocessing others. Other manufactured rice products, such as quick -cooking rice and dry breakfast cereals, may be similarly affected by excessive chalkiness. The processors usually place limitations on the amount of chalk permissible in rice purchased for manufacturing these products.

The Grading Service classifies chalky kernels as kernels which are one-half or more chalky. The type of chalk (location of chalky spots on the endosperm), as well as the amount of chalk, is important to some processors of rice, as certain types of chalk affect the quality of their particular processed product more than other types. Depending on the location of chalk on the kernel, the chalky spots may be referred to as "white belly", "white core", and "white back". Determination of the amount and type of chalk in rice is currently made by visual examination.

D. Red Rice

Red rice (Oryza saliva L.) is a serious weed pest in many rice-growing areas. It resembles cultivated varieties but tillers more profusely and shatters easily after maturity. The grains show a marked dormancy following ripening and have the ability to retain their viability in the soil for several years.

The red seed coat (pericarp), usually in the form of a firmly adhering bran, detracts from the appearance and market value of the commercial product. The bran of red rice adheres to the endosperm so firmly that it is difficult to remove in milling without causing excessive breakage of the cultivated variety.

As with damaged and chalky kernels, red rice must currently be determined by visual inspection. Color sorters are efficient in separating red rice (with a substantial amount of bran adhering) from white rice, but are rather inefficient in separating kernels of red rice having only light streaks of the bran remaining.

E. Seeds or Kernels

Seeds or kernels, either whole or broken, of any plant other than rice are classified as seeds. The rice industry usually considers as objectionable those kinds of seeds difficult to remove by screening, sieving, or aspiration because of their similarity to rice in size, shape, and density. Examples of objectionable seeds are from the senna family, Sorghum almum Parodi and Aeschynomene virginica (L.) B.S.P. Seeds of this type must be removed by hand separation.

F. Odours

Odours in rice other than those normally associated with clean, sound, rough, brown, milled, and parboiled rice of naturally scented and nonscented varieties are considered objectionable and usually drastically lower the value of the rice. Included in the same category with musty or sour odours are moldy ground odours, insect odours, and rancid and sharp acrid odours. Commercially objectionable foreign odours for grading purposes include those of fertilizers, hides, oil products, skunk, smoke, and decaying animal and vegetable matter. Odours of fumigants, except under circumstances specified are also considered as objectionable foreign odours. Determinations of odours are made subjectively by trained inspectors on the rice as a whole, usually at the time of sampling.

IX. MILLING QUALITY

The criteria of rice quality described above and the subjective and objective methods discussed in determining them are of value primarily because they are indicative, to some extent, of the milling quality of rice and of the suitability of rice for specific cooking and processing uses as human food. However, other more definitive criteria are required to evaluate rice milling, cooking, and processing qualities, and these are described in subsequent sections of this chapter.

A. Milling Yield

Milling yield is one of the most important criteria of rice quality. The objective in milling rice is to remove the bran layers and germ with a minimum of breakage of the whole kernels, with the preservation of most of each kernel in its approximate original shape. It therefore becomes very important from a marketing standpoint to determine the milling yield of rice accurately.

In determining the milling yield of rough rice, foreign material (dockage) is first separated. Then the rice is shelled to remove the hulls, then milled to remove most of the bran layers and germs, and finally sized to determine the yield of whole and broken kernels. Two values of milling yield are commonly used in grading: whole-kernel rice yield and total milling yield. The whole-kernel yield is the quantity of whole kernels of milled rice (usually well-milled) that can be obtained from a given quantity of uncleaned rice. Total milling yield is the quantity of whole and broken kernels of milled rice that can be obtained from a given quantity of uncleaned rough rice.

As commercial milling machinery is gradually improved, a problem arises in using any one device to determine accurately the milling yield of rice. Most commercial rice-milling facilities, therefore, rely upon methods and laboratory mills adapted to fit their individual needs. However, for official grading, a standardized procedure is necessary. A machine which would give the ultimate maximum milling yield would probably best serve the needs of the rice industry and trade.

A large number of factors can affect both total and whole-kernel milling yields. Some of these-such as foreign-material content, chalky- and immature-kernel content and damaged-kernel content-are obvious. Other factors which can seriously affect the milling yield are variety, grain type, growing conditions, harvesting method (including combine efficiency), control of drying operations, and-of particular importance-effects due to adsorption and desorption. For some time it has been known that rice can be easily damaged by conditions occurring during rapid drying or in rewetting of the kernels through moisture adsorption. It is shown that rapid changes in environmental conditions can cause rice to crack or fissure milling yields are affected by environmental conditions which exist in a rice mill. Therefore, the environmental conditions in a rice-grading laboratory probably should be controlled. Furthermore, the condition of the rice sample should perhaps be controlled with respect to moisture content and temperature prior to milling. Neither of these procedures is commonly practiced in grading laboratories at the present time, except that samples of rice to be tested are usually allowed to equilibrate for a few hours with laboratory conditions prior to milling. Most of the rice-inspection laboratories also allow hot milled rice to temper or cool slowly in semi-closed containers prior to separating whole kernels from broken kernels.

The final step in determining an estimated milling yield is the separation of whole-kernel milled rice from broken kernels in the sample: A high quantity of brokens is indicative of poor milling quality, whereas a high percentage of whole kernels is indicative of high quality. All rice markets discriminate greatly against broken rice.

Various types of sieves, indent cylinders, and graders have been developed for separating the various sizes of brokens.

B. Degree of Milling

Degree of milling is a measure of the extent to which the bran layers and germ have been removed from the rice endosperm. A majority of the consumers prefer well-milled rice with little or no bran adhering to the endosperm. Ironically in countries where rice is the principal food, the preference is generally for well-milled rice, which is decreased in nutrient value since the proteins, fats, vitamins, and minerals are concentrated in the germ and outer layer of the starchy endosperm. Furthermore, in rice that is overmilled, there is a reduction in both the total and whole-kernel milling yields, with a subsequent loss in market value.

In general, there are four degrees of milling: well-milled, reasonably well-milled, lightly-milled, and under-milled. These descriptions are nebulous in that there is no precise definition for them.

Determinations of the degree of milling are made largely by visual inspection both in commercial milling operations and in grading laboratories. A technician can be trained to become quite efficient in a particular system, but from a world-market viewpoint an objective method is needed.

A number of objective methods have been proposed. Some of these consist of dye-staining techniques designed to emphasize the residual bran for easier visual observation.

Probably one of the most reliable objective methods presently available is a chemical procedure. It was found that the amount of fat extracted from whole milled rice was linearly related to the amount of bran removed up to about 6% of the original rice by weight. While this method is generally reliable, it requires considerable chemical skill and a suitable, fat-extraction apparatus, and is rather time-consuming. Therefore, this method has received only limited use in rice-milling facilities and grading laboratories. It has received wider use as a research method because of its accuracy.