GARLIC OIL AND POWDER

INTRODUCTION

GARLIC OIL

Garlic oil is nothing but an essential oil of the plant family liliaceae. The bulbs or cloves of the common garlic (allium stivum liliaceae) have been used since antiquity, particularly, in mediterranean countries, as a popular prophylactic and curative against all kinds of intestinal ailments.

It is well known fact that whole (undamaged) bulbs of garlic possess a relatively weak odour. However when cut up or crushed, the bulbs emit their well known powerful and obnoxious odour, due to an essential oil consisting chiefly of disulfides.

Garlic oil contains following constituents: -

- Allyl-propyl disulphide C6H12S2.

- Diallyl disulphide C6H10S2.

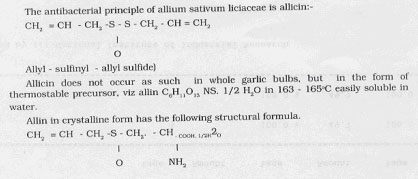

And two other sulphur containing compounds. Steam distilling fresh garlic bulbs obtained from 0.1 to 0.2% of volatile oil. Distillation of the whole plant gave from 0.06 to 0.10 percent of oil. the actual mechanism of the reaction, by which the antibacterial principle of garlic, and the disulfides in the volatile oil, originate, was finally elucidated only a few years ago.

GARLIC POWDER

Garlic Powder means garlic in powder form, powder form means moistureless or dehydrated form. In other words, Dehydrated Garlic is in grinded form.

Dehydration is defined industrially as drying by artificially produced heat under carefully controlled conditions of temperature, humidity and air flow. The term applied to all dried product regardless to the method of drying.

The garlic powder is manufactured by many large scale and small scale food processing units in India. The technical details and other details are available in our country and a sizable amount of dehydrated garlic is exported to other countries. The dehydrated garlic powder is used in flavoring of many food products and in Ayurvedic medicines.

USES AND APPLICATIONS

GARLIC OIL

Garlic oil finds its uses in the following areas:-

- Garlic is recommended for internal use as a tonic and stimulant to the stomach.

- It is also used as a vermiuge.

- It finds its extensive use in spice foods.

- Its major use in medicines i.e. it is prescribed to patients with high blood ressure.

- It is also used in soaps, canned goods and table sauces.

- It is also used in consumer products like soaps. Cosmetics perfumes etc.,

GARLIC POWDER

- Tomato soups are flavoured with the addition of garlic powder.

- Canned soups and meat products use garlic powder for flavoring purposes.

- In sausages, hamourger and salami, the dehydrated garlic powder is added to give the typical flavour of garlic.

- Certain salad dressings also use garlic powder.

- Garlic powder is also used in Ayurvedic medicines for improper digestion, throat troubles and for coughs and bad colds.

PROPERTIES

It has pungent odour.

It is colorless clear liquid.

Different garlic oils obtained from different garlic have different specific gravity and optical rotation e.g.

| 1. |

Specific gravity at 15o |

-- |

1.046 - 1.057 |

| |

Optical rotation |

-- |

10o |

| 2. |

Specific gravity at 15o/15o |

-- |

1.5578-1.5745. |

| |

Refractive index at 20o |

-- |

1.5745. |

BIS SPECIFICATIONS

| Garlic |

IS: |

3240-1965 |

| Dehydrated Garlic |

IS: |

5452-1969. |

MARKET POSITION AND SCOPE

Garlic oil and Powder from raw garlic has an excellent scope for development. This product has a high level of scope, though it's technology is not very old. It's potential still stand to be explored.

At present, this product is in short supply, so there is high demand in the market for garlic oil. Thus, the gap between demand and supply still exists.

Garlic oil is very widely used in spice food and in pharmacuetical industry to produce different medicines. Though, its use was even explored by the primitive people also, particularly in mediterranean countries, as a popular prophylofic and curative against all kins of intestinal ailments, chronic infection of the stomach and dysentry , typhoid fever, cholera etc. Garlic possesses a considerably high curative power; thus a number of attempts had been made to isolate its antibacterial principle. Few years back, the component allicin was identified, which paved the way to process garlic and other garlic oil having a very high scope in the market.

The demand for this product is increasing with a rate 15%, thus, this industry possesses a bright future and allows the new enterpreneures to enter in the field of production of garlic oil by establishing new industries.

All the required raw materials and machineries are indigeneously available in our country. So there is no need to import them, hence saving the foreign exchange of the Government.

PRESENT MANUFACTURERS

M/s KMA Overseas Pvt.ltd.,

5 A/7, Ansari Road,

Daryaganj,

New Delhi-2.

M/s. Adarsh Suppliers Co.

2/26, Roop Nagar,

Delhi 110 007.

M/s. A.P. Products & Agencies,

Sadak Jung Devadi,

22-5-411-13, Punjeshah,

Hyderabad - 2.

M/s. Bombay Grain Crushing & Spice Mills,

72, Kalyan Street, Dana Bunder,

Mumbai 9.

M/s. Eve's Foods,

5, Kandaswamy Road,

R.A. Puram,

Chennai 28 (TN).

M/s. Rajkumar Lal chand Bhola,

Garam Masala, Dhamtari,

Dist. Raipur (MP).

LIST OF PLANT & MACHINERY

- Washer (mil steel) 1 No.

- Crusher Rotary Disc Type 1 No.

- Distillation Column with All Auxilliaries,i.e. Condenser, Renoiler etc.

- Storage Tank for Garlic Oil (Stainless Steel)

- Boiler (coal Fired)

- Miscellaneous equipemnts like knives, plates etc.

- Roll Breaking Machine (Stainless Steel)

- Vibrating Screen (Stainless Steel)

- Flaking Rolls (Stainless Steel)

- Flow Drier with Belt Conveyor

- Hammer Mill

- Intermediate Collection Tank

LIST OF RAW MATERIALS

- Garlic with leaves etc. obtained from fields 2,21,500 Kg.

- Packing Material for Oil & Powder

- Lables etc.

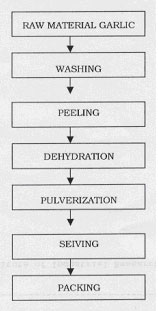

MANUFACTURING PROCESS OF GARLIC POWDER

The manufacturing process of garlic powder requires following operations.

- Washing.

- Peeling.

- Dehydration.

- Pulverization.

- Packing.

WASHING

The fresh garlic as obtained from the vegetable market includes many contaminants like soil, leoues of other vegetables etc. It is very essential to wash the garlic purchased from the market before proceeding to any other process. The washing operation is performed by water spraying or in rotary washers.

PEELING

The outer leaves of garlic after washing are removed by peeling operation. Water sprayers used in first step assist peeling besides loosening the dirt. Peeling may be affected by steaming, radiant heat, or by heating over gas flames & tumbling in washer flame. the last technique is used for peeling of onion & garlics. In small-scale units, hand operated peeling machine are used for removing the outer layers of garlic. The peeling process is again followed by the washing by spraying water.

DEHYDRATION

Prior to dehydration, another operation is sometimes performed with certain limitations. This process is known as sulphitation. A small amount of sodium sulphate solution is spread on the sliced garlic prior to steaming. Sulphitation greatly prolongs the storage life of vegetables. garlics & onions, but treatment reduces their pungency. Sulphitation also protect the garlic and other vegetables against scorching damage during dehydration.

The modern process of dehydration consists of the removal of moisture from garlic by the application of heat usually in the presence of controlled flow of air. If the air used in drying garlic is allowed to escape into the atmosphere after it passage through the dehydrator, a great deal to heat is lost. The garlic may become overdried if the spent air is recirculated in larger quantities. this condition is avoided to a large extent of the relative humidity of the air is increased sufficiently, which can be done to a large degree by return of some of the spent air. Because of these facts, it is customary in modern dehydrators to provide for recirculation of a portion of air used in drying.

PULVERIZATION

The size reduction of dehydrated garlic will give garlic powder. The product may be ground to give a powder of 80 mesh or coarser size. The grinding operation is performed in a pulverizing machine. After grinding the product, the product is screened to give a dehydrated garlic powder of homogeneous composition & now it is ready for packing.

PACKING

The packing is convenient in Polythene bags of size 20 cm. width.

FLOW SHEET DIAGRAM FOR GARLIC POWDER

PROCESS OF MANUFACTURE FOR GARLIC OIL

The outline of the process is as follows:

First of all undersired materials e.g. soil, leaves, grass etc. are cut off and washed thoroughly with water. After washing garlic bulbs, they are crushed to convert allin to allicin.

Allicin is rather unstable it can be isolated by steamdistillation only at reduced pressure. Allicine possesses an odour characteristic of garlic but is not obnoxious. On steamdistillation at atmospheric pressure allicin is decomposed to diallyl disulfide and other disulfides, which explains why the volatile garlic oil obtained by steam distillation of the bulbs or of the whole plant consist chiefly of the disulfides.

In the fermentation cleanage of allin, the parent substance present in the uncrushed material, allows is therefore only anintermediary product, being finally converted into the obnoxious disulfides so characteristic of the volatile oil.

PROCESS FLOW SHEET FOR GARLIC OIL

IMPORTING COUNTRIES OF GARLIC POWDER

- JAPAN.

- U.K.

- U.S.A.

- CANADA.

- FRANCE.

- G.F.R.

PLANT ECONOMICS

0

| 1. |

RATED PLANT CAPACITY |

= |

1138.34 KGS/day |

| 2. |

TOTAL LAND AREA REQUIRED 1000 sq.mt |

Rs. |

7,00,000.00 |

| 3. |

BUILDING |

Rs. |

13,50,000.00 |

| 4. |

PLANT & MACHINERY |

Rs. |

21,25,000.00 |

| 5. |

OTHER FIXED ASSETS |

Rs. |

4,65,000.00 |

| 6. |

FIXED CAPITAL |

Rs. |

46,40,000.00 |

| 7. |

RAW MATERIAL/MONTH |

Rs. |

18,72,000.00 |

| 8. |

WORKING CAPITAL FOR 3 MONTHS |

Rs. |

66,21,300.00 |

| 9. |

COST OF PROJECT |

Rs. |

62,95,325.00 |

| 10. |

TOTAL CAPITAL INVESTMENT |

Rs. |

1,12,61,300.0 |

| 11. |

RATE OF RETURN |

= |

26.44 % |

| 12. |

B.E.P. |

= |

57.90 % |

For comprehensive and exhaustive details on GARLIC OIL AND POWDER ask for Market Survey Cum Detailed Techno Economic Feasibility Report.

NATIONAL INSTITUTE OF INDUSTRIAL RESEARCH

106-E, P.B. No. 2162, Kamla Nagar (Nr. Delhi University), Delhi-110007

E-Mail: niir@vsnl.com