The demand for innovative printing practices has been on a high in recent times. Printing ink is a mixture of colouring matter dispersed or dissolved in a vehicle or carrier, to form a fluid or paste which is used for printing on a substrate and then dried. Depending on the process and end use, inks are classified into letterpress, lithographic, flexographic, rotogravure, and others.

Ink is a complex medium composed of solvents, pigments, dyes, resins, lubricants, solubilizers, surfactants, particulate matter, fluorescers, and other materials. The components of inks serve many purposes; the ink’s carrier, colorants, and other additives are used to control flow and thickness of the ink and its appearance when dry.

Today's inks are divided into two classes: printing inks and writing inks. Printing inks are further broken down into two subclasses: ink for conventional printing, in which a mechanical plate comes in contact with or transfers an image to the paper or object being printed on; and ink for digital nonimpact printing, which includes ink-jet and electrophotographic technologies.

Printing ink industry is seen augmenting its turnover on the back of a strong growth in its user industries such as newspaper, flexible packaging and publishing. The Indian print industry will be worth around $27 billion by 2012. All products and services that cater to banking, telecom, education, pharmaceuticals and consumer goods segments in the Indian market have grown. Today, India is increasingly viewed as a print outsource destination which means that the exports in the publishing business have also grown.

The Main Segments of the Indian Printing Inks Industry includesNewspaper Inks, Sheet fed offset, Flexographic & Gravure Inks, Can Coatings & Inks, Screen Printing Inks, Speciality Inks, Inkjet Inks, Marking & Coding Inks, UV Coatings inks, etc.The Market leaders in the ink industry includes:Seigwerk, Huber, DIC, Organic Coatings, Fujifilm, Sakata, Flint, etc.

The printing ink industry in India is dominated by multinational companies. Besides DIC, Flint and Sakata of Japan specialize in the manufacture of inks.

Among the domestic players, Hindustan Inks has large capacities in India and now in the US as well.

Currently, the printing ink market in India is worth Rs.16 billion and is growing at the rate of 15-18 percent yearly. There are around 25 – 35 ink makers in the medium size category and an estimated 200 ink makers in the small scale segment. In terms of tonnage of ink manufactured in India, it is estimated to be 110 million tonnes. The ink demand in the Newspaper Industry grew rapidly over the past 3 – 4 years by nearly 20%. In spite of the global meltdown, the newspaper industry has grown nearly 25% in readership. The Packaging Industry which is another main consumer of printing ink, has witnessed a growth of approximately 12.5% and the corrugated packing industry grew by over 8%.The flexible packaging growth is in excess of 15% with the expansion of the food and retail industry.Another area of high growth driver is expected in the Can Coating segment which is presently at 3 – 4% growth but is expected to show an increase when more food products like meats and seafood are increasingly packaged and the beverage industry expands with increase in consumption of Sodas, Soft Drinks, Tea,Coffee and Beer. Other segment of Ink consumption in screen printing is also showing steady growth trends. The Electronic Industry has special demands for inks for PCBs, Membranes and Touch Panels, etc.The Inkjet ink requirement in the country is expanding rapidly. Though the majority of inks for this industry are presently imported, there is a large scope for new players. There is a great opportunity and demand for Indian inks makers as well as International Brands in Indian markets.

Reasons for buying our reports:

This report helps you to identify a profitable project for investing or diversifying into by throwing light to crucial areas like industry size, market potential of the product and reasons for investing in the product

This report provides vital information on the product like its characteristics and segmentation

This report helps you market and place the product correctly by identifying the target customer group of the product

This report helps you understand the viability of the project by disclosing details like machinery required, project costs and snapshot of other project financials

The report provides a glimpse of government regulations applicable on the industry

The report provides forecasts of key parameters which helps to anticipate the industry performance and make sound business decisions.

Our Approach:

Our research reports broadly cover Indian markets, present analysis, outlook and forecast for a period of five years.

The market forecasts are developed on the basis of secondary research and are cross-validated through interactions with the industry players

We use reliable sources of information and databases. And information from such sources is processed by us and included in the report

Please choose a project below related to this category.

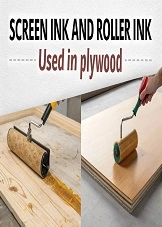

The plywood industry is one of the fastest-growing sectors in the global construction and furniture markets, with the India Plywood Market valued at I...

|

Capacity : Screen Ink: 1,000 Kgs Per Day Roller Ink: 1,000 Kgs Per Day |

Plant and Machinery cost: 57 |

|

Working Capital : 0 |

Rate of Return (ROR): 27 |

|

Break Even Point (BEP): 61 |

TCI :

|

|

Cost of Project : 240 |

Digital printing refers to methods of printing from a digital-based image directly to a variety of media. It usually refers to professional printing w...

|

Capacity : - |

Plant and Machinery cost: - |

|

Working Capital : - |

Rate of Return (ROR): 1.00 |

|

Break Even Point (BEP): 0.00 |

TCI : - |

|

Cost of Project : 0 |

Inkpad or Stamp Pad is a small box which contains a pad of cloth or other material. It is impregnated with ink (the pad is inky). A marker is pressed...

|

Capacity : - |

Plant and Machinery cost: - |

|

Working Capital : - |

Rate of Return (ROR): 1.00 |

|

Break Even Point (BEP): 0.00 |

TCI : - |

|

Cost of Project : 0 |

Oil based is the most popular type of ink and can be used in all print making processes. It dries by oxidation and can be used on most papers. It can...

|

Capacity : 2 MT/Day |

Plant and Machinery cost: Rs.22 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 42.00 |

|

Break Even Point (BEP): 59.00 |

TCI : Cost of Project : Rs.544 Lakhs |

|

Cost of Project : 54400000 |

Toner is a powder used in laser printers and photocopiers to form the printed text and images on the paper. In its early form it was simply carbon po...

|

Capacity : 6000 Kgs./Day |

Plant and Machinery cost: 2959 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 42.00 |

|

Break Even Point (BEP): 33.00 |

TCI : Cost of Project : 4048 Lakhs |

|

Cost of Project : 404800000 |

Ink is a liquid or paste that contains pigments and/or dyes and is used to color a surface to produce an image, text, or design. Ink is used for drawi...

|

Capacity : 300 Kltrs./Annum Solvent Ink, 300 KLtrs./Annum Aqeous Ink |

Plant and Machinery cost: 150 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 44.00 |

|

Break Even Point (BEP): 52.00 |

TCI : Cost of Project : 398 Lakhs |

|

Cost of Project : 39800000 |

Flexographic inks are used in printing packaging materials, including cartons, corrugated containers, paper and plastic bags, food containers, newspap...

|

Capacity : 150000 Kg./Annum |

Plant and Machinery cost: 36 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 47.00 |

|

Break Even Point (BEP): 41.00 |

TCI : 139 Lakhs |

|

Cost of Project : 0 |

Flexographic inks are used in printing packaging materials, including cartons, corrugated containers, paper and plastic bags, food containers, newspap...

|

Capacity : 500 Kg./Day |

Plant and Machinery cost: 35 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 47.00 |

|

Break Even Point (BEP): 41.00 |

TCI : 139 Lakhs |

|

Cost of Project : 0 |

Early accounts of inks, even including the older patents, are remarkable is being purely qualitative. During the last century, ink formulation has be...

|

Capacity : 500 Kg./Day |

Plant and Machinery cost: 20 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 47.00 |

|

Break Even Point (BEP): 43.00 |

TCI : 107 Lakhs |

|

Cost of Project : 0 |

Lime is manufactured from lime stone. Lime is mainly used for manufacture of hydrated lime. Hydrated lime is a dry powder obtained by treating quick...

|

Capacity : 600 MT/Day |

Plant and Machinery cost: 131 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 24.00 |

|

Break Even Point (BEP): 42.00 |

TCI : Cost of Project : 548 Lakhs |

|

Cost of Project : 0 |

In modern time ball pen refills are being produced from plastic materials and is having bright future in specially India. Ball pen refill is stocked...

|

Capacity : 10,000 Nos./day |

Plant and Machinery cost: 4 Lakh |

|

Working Capital : 30 Lakh |

Rate of Return (ROR): 43.00 |

|

Break Even Point (BEP): 47.00 |

TCI : 30 Lakh |

|

Cost of Project : 0 |

Flexography originated in about 1900 as “aniline-dye rubber printing, used for simple packaging prints. Flexographic printing inks are liquid, unlik...

|

Capacity : 5 MT / Day |

Plant and Machinery cost: 34 Lakhs |

|

Working Capital : - |

Rate of Return (ROR): 52.00 |

|

Break Even Point (BEP): 34.00 |

TCI : 316 Lakhs |

|

Cost of Project : 0 |