Decorative laminates are strong fabric materials used in both residential and commercial furniture. They receive a phenolic resin acid coating before being decorated with artificial resin and the chosen designs. These laminates are utilised for carpentry, emerging room counters, and countertops since they are heat, stain, and scratch resistant. They observe applications in lodging facilities, medical facilities, shopping centres, airports, academic institutions, and commercial infrastructure.

Visit this Page for More Information: Start a Business in Wood Processing Industry

Click here to send your queries/Contact Us

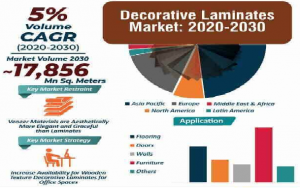

In 2021, the decorative laminates market in India had a value of US$ 1.6 billion. Looking ahead, NPCS projects that the market will grow at a CAGR of 6.13% from 2022 to 2027, reaching US$ 2.3 billion. We are constantly monitoring and assessing the direct as well as indirect impact of the pandemic on various end-use sectors while keeping in mind the COVID-19 uncertainties.

The demand for the decorative laminated sheet is increasing in India tremendously. As it is easy to maintain and affordable customers are vouching for it, making it a trending product in the market. As NPCS headed more into the market we realized there is a lot of potential for sunmica sheets. Gathered are some of the information which may help you make a decision.

Related Business Plan: Wood and Wood Products, Plywood, Board, Particle Board, Wooden Furniture, Bamboo, Engineered wood, Forest product, Lumber, Tree, Wood drying, Wood plastic composite, Door, Window, Modular Furniture, Timber, Woodworking, Decorative Laminated Sheets

Indian Market

India's market for decorative laminates is primarily driven by rising living standards and rising consumer spending per capita on home furnishings. The popularity of ready-to-assemble (RTA) cabinets, flooring, and furniture have also influenced buyers to choose more contemporary styles for their home furnishings.

Furthermore, the need for decorative interior items like laminates in indoor sports clubs, gymnasiums, auditoriums, and convention centres has expanded due to India's rapid growth of its commercial infrastructure.

Additionally, stylish laminates have become quite popular across the nation because they are simple to install and don't require using nails or staples to attach them to the flooring or walls.

Read Similar Articles: WOOD AND WOOD PRODUCTS

Raw Material

Laminates are made of papers that have been given a chemical resin treatment to give them strength and rigidity. The following is a list of the essential elements needed during production.

· Paper. It is primarily recognised as a Kraft paper.

· Phenolic resin

· Decorative Paper

· Melamine resin

· Transparent paper

Watch Video: Decorative Laminated Sheet (Sunmica) | Laminated Sheets for Furniture | Cupboard Manufacturing Plant

Machinery Required

· Machines for cooling and drying.

· Machines for cutting papers and laminate sheets into standard or desired sizes by market demands

· Steel Plates Pressed Hydraulically (to separate various laminate sheets while pressing, and to cut desired patterns and textures)

· Sanding tools

Related Feasibility Study Reports: Decorative Laminated Sheets (sunmica) - Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities

Laminate Manufacturing Process

1. Dipping Paper in Resin

The paper is first immersed in resins throughout the production process. The paper used to create the laminate's foundation is soaked in a container filled with phenolic resin. When paper is soaked, it doesn't just become wet; rather it absorbs the resin and becomes saturated with it. Decorative paper and clear paper are both equally saturated and steeped in phenolic resin. These surfaces are made sturdier, resistant to wear and tear, and durable with the help of resin.

After soaking the saturated papers are then dried out. After drying the paper gains new physical qualities and becomes brittle and rigid.

2. Pressing and Bonding

The next step is hard pressing these papers together at high pressure and temperature. Hydraulic pressure is used for this. The sheets or papers are piled on top of one another. The bottom sheet is made of brown paper, followed by a decorative sheet and a layer of clear translucent paper at the top. Steel separator plates are inserted between each of the laminates that will be pressed as they are stacked one on top of the other.

Steel plates are made to carry designs or textures that are etched onto the laminate sheet's surface during pressing. Because pressing is one of the most crucial steps in creating laminate sheets, decorative laminates are frequently referred to as HPL and HPDL.

Read our Book Here: Directory/ Database/ List of Wood, Plywood, Furniture and Allied Products Manufacturers, Dealers & Exporters in India (4th Edition) [.xlsx, excel format]

3. Sanding

This is the last process where the bottom side is uniformly sanded by a sanding machine. This surface is better suitable for adherence to surfaces. Carpenters apply glue to this sanded surface before attaching these laminate sheets to plywood or other base substrate materials.

Conclusion

The decorative laminates market in India is broken down into sub-segments, and NPCS analyses the major trends in each of these segments and gives 2022–2027 country and regional estimates. Our report has segmented the market according to product type, application, end-use, texture, pricing, and sector. Contact us for more reports and data analysis.

If you need information about Manufacturing Business of Decorative Laminated Sheet (Sunmica), then contact NPCS. The project report from Entrepreneur India enables you to choose a profitable project for investing in or diversifying into by shedding light on crucial areas including business size, the product's market potential, and the motivations behind investing in the product. By defining the target client organisation for the product, the study helps you promote and position it effectively.

Watch other Informative Videos: Wood and Wood Products, Plywood, Particle Board, Wooden Furniture, Bamboo, Forest Product, Wood Plastic Composite, Timber and Woodworking

Click here to send your queries/Contact Us

Reasons for Buying NIIR Report:

● Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

● Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

●Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

● Our Report provides indispensable buyers' data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

● Our report provides forecasts of key parameters which help to anticipate the industry performance.

● We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

See More Links:

· Start a Business in Asia

· Start a Business in Potential Countries for Doing Business

· Best Industry for Doing Business

· Business Ideas with Low, Medium & High Investment

· Looking for Most Demandable Business Ideas for Startups

· Startup Consulting Services

· Start a Business in Africa

· Start a Business in India

· Start a Business in Middle East

· Related Videos

· Related Books

· Related Projects

· Related Market Research Reports

DPP_20Art22