Titanium dioxide, also known as TiO2, is a naturally-occurring mineral that is commonly used as a whitening agent and a UV absorber in a wide range of products, including paint, sunscreen, and food. It is a safe and effective ingredient that has been extensively studied and used for many years in many industries. Due to its excellent whitening, UV resistance, high refractive index, and chemical stability, it is widely used in many fields such as coatings, plastics, papers, inks, foods, cosmetics, and pharmaceuticals.

Visit this Page for More Information: Start a Business in Chemical Industry Projects

Understanding the Manufacturing Process for Titanium Dioxide from Rutile and Ilmenite Ores:

The manufacturing process for titanium dioxide from rutile and ilmenite ores typically involves several steps. The first step is to extract the ores from the ground and beneficiate them to remove impurities. This typically involves crushing and grinding the ores and then using various physical and chemical processes to separate the titanium-bearing minerals from the other minerals in the ore.

Next, the titanium-bearing minerals are further processed to remove any remaining impurities and to produce the intermediate product, titanium tetrachloride (TiCl4). This can be done through the Chlorination of Titanium ores. The titanium tetrachloride is then purified and reacted with oxygen to produce titanium dioxide. This process is known as the "sulfate process" or "chloride process"

Finally, the titanium dioxide is processed further to produce the desired final product, which can take the form of a powder, a paste, or a slurry. This can include steps such as particle size control, surface treatment, and coating to enhance the properties of the final product.

Related Business Plan: Chemicals (Organic, Inorganic, Industrial)

Assessing the Market Demand for Titanium Dioxide:

The Global Market Size:

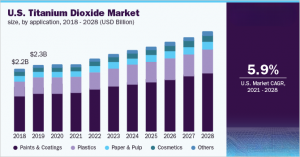

The global market size of titanium dioxide is significant and has been growing in recent years. According to research, the global titanium dioxide market size was valued at USD 14.67 billion in 2020, and it is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028.

The growth in the market is attributed to the increasing use of titanium dioxide in various industries such as paints and coatings, plastics, papers, inks, and food, among others. The growing demand for titanium dioxide in the paint and coating industry is expected to be a major driver for the market. The use of titanium dioxide in the paint and coating industry improves the durability and resistance of the paint, which makes it suitable for a wide range of applications.

Additionally, the growing construction industry, especially in developing economies, is expected to boost the demand for titanium dioxide. The increasing use of titanium dioxide in the construction industry improves the durability and resistance of building materials.

Read Similar Articles: CHEMICAL INDUSTRY

The Asia Pacific region is expected to dominate the global market due to the presence of a large number of manufacturers and the increasing construction activities in countries such as China and India.

The Indian Market Size:

The Indian market size of titanium dioxide is also significant and has been growing in recent years. According to research, the Indian titanium dioxide market size was valued at around USD 394.5 million in 2020 and it is projected to grow at a CAGR of 5.5% from 2021 to 2028.

India has a growing market for Titanium Dioxide as it is a major consumer of the chemical and has a considerable number of manufacturers and suppliers. The country has a high demand for titanium dioxide in the paint and coating industry, as well as in the construction and plastics industry.

It is worth noting that the market size and growth rate may change due to several factors such as economic conditions, new regulations, and technological advancements, among others.

Benefits of Titanium Dioxide:

Titanium dioxide (TiO2) is a widely used material that offers a variety of benefits, including:

1. TiO2 is an effective ultraviolet (UV) absorber, which makes it an ideal ingredient in sunscreens, cosmetics, and other products that protect the skin from UV damage.

2. TiO2 is a highly reflective white powder that is used as a whitening agent in a wide range of products, including paint, toothpaste, and food.

3. TiO2 is used as a pigment in a wide range of products, including paint, plastics, and inks. It provides excellent whiteness, brightness, and hiding power, which makes it a popular choice in these industries.

4. TiO2 is a highly durable material that is resistant to weathering, chemicals, and UV radiation. This makes it an ideal ingredient in products that are exposed to these conditions, such as exterior paints and roofing materials.

5. TiO2 is biocompatible, meaning it is not harmful to living organisms. It is used in dental products, medical implants, and drug delivery systems.

6. TiO2 is also known for its environmental benefits. It has photocatalytic properties, which means it can break down pollutants and purify the air. This feature makes it useful for applications such as self-cleaning surfaces and air purification.

Related Feasibility Study Reports: Chemicals (Organic, Inorganic, Industrial) Projects

7. TiO2 is a cost-effective and widely available material, which makes it an attractive option for many industries and applications.

It is worth noting that the benefits of titanium dioxide may vary depending on the specific application, and some of its uses may raise concerns such as its potential health effects and environmental impact, further research is needed to understand these concerns and to ensure the safe and sustainable use of titanium dioxide.

Raw Materials Requirement:

The manufacturing of titanium dioxide (TiO2) involves several stages, starting with the sourcing of raw materials. The primary raw materials required for the manufacturing of TiO2 are rutile and ilmenite ores.

· Rutile Ore

· Ilmenite Ore

· Sulfuric acid

· Chlorine

· Natural gas or fuel oil

· Water

· Other raw materials such as catalysts, acids, and other chemicals

It is worth noting that the specific raw materials required for the manufacturing of TiO2 may vary depending on the specific manufacturing process and the type of TiO2 being produced (anatase or rutile).

Acquiring the Necessary Equipment and Machinery:

The manufacturing of titanium dioxide (TiO2) requires a variety of equipment and machinery, including:

· Ore processing equipment such as crushers, grinders, and pulverizers.

· Leaching equipment such as leaching tanks and agitators.

· Filtering equipment such as filters and centrifuges.

· Chlorination equipment such as chlorination tanks and reactors.

· Drying equipment: This includes equipment used to dry the TiO2, such as dryers and kilns.

· Milling equipment such as ball mills and roller mills.

· Packing and bagging equipment such as bagging machines and palletizers.

· Laboratory equipment such as spectrophotometers and particle size analyzers

· Safety equipment such as respirators, goggles, and gloves.

· Electrical and mechanical equipment such as control systems, pumps, and motors.

It is worth noting that specific equipment and machinery required for the manufacturing of TiO2 may vary depending on the specific manufacturing process, the size and type of facility, and the end-use of the TiO2. Additionally, many of the equipment and machinery required for TiO2 manufacturing are common in the chemical, mining, and metallurgical industry and can be sourced from various suppliers.

Read our Books Here: The Complete Technology Book on Chemical Industries

Ensuring Compliance with Regulatory Requirements:

Starting a manufacturing business for titanium dioxide (TiO2) typically requires various registration, certificates, and licenses. The specific requirements will vary depending on the location and jurisdiction of the manufacturing facility. Some of the common registration, certificates, and licenses required include:

· Business Registration

· Environmental permits

· Safety and health permits

· Fire safety certificate

· Zoning and land-use permits

· Quality certifications

· Import and export licenses

· Tax registration.

Identifying Potential Suppliers of Raw Materials:

Raw materials are an essential component of the manufacturing business of titanium dioxide (TiO2). Identifying potential suppliers of raw materials can help ensure a steady supply of materials and minimize disruptions to the manufacturing process.

Potential suppliers of Ilmenite and rutile ores can be found in countries that have large deposits of titanium minerals, such as Australia, Canada, South Africa, and India.

Potential suppliers of sulfuric acid can be found in chemical companies and chemical supply companies.

Potential suppliers of chlorine can be found in chemical companies and chemical supply companies.

Potential suppliers of carbon can be found in carbon supply companies.

Potential suppliers of other chemicals such as caustic soda and hydrochloric acid can be found in chemical companies and chemical supply companies.

Land Acquisition:

Land acquisition is an important aspect of starting a manufacturing business for titanium dioxide (TiO2). The amount of land required will depend on the size of the manufacturing facility and the specific processes involved in the production of TiO2. A typical TiO2 manufacturing facility will require a large piece of land to accommodate the raw material storage area, the production unit, the waste management area, and the administrative and storage buildings.

When acquiring land for a TiO2 manufacturing facility, it is important to consider factors such as the location, accessibility, proximity to raw materials and transportation, environmental and zoning regulations, and the availability of utilities.

Watch other Informative Videos: Production of Titanium Dioxide (TiO2) | Highly Profitable Chemical Business Ideas

Investment:

Starting a manufacturing business for titanium dioxide (TiO2) requires a substantial investment, as the process involves the acquisition of raw materials, equipment, machinery, and land.

Estimates for starting a medium-sized TiO2 manufacturing plant can range from tens of millions of dollars to hundreds of millions of dollars. This investment will cover costs such as purchasing or leasing land, acquiring raw materials, installing machinery and equipment, constructing buildings and infrastructure, obtaining permits and certifications, and hiring personnel.

Investment for a TiO2 manufacturing business can come from a variety of sources such as personal savings, bank loans, venture capital, private equity, or government grants. It is important to have a clear business plan, a detailed budget, and a strong understanding of the market and industry to attract potential investors.

Conclusion:

In conclusion, titanium dioxide (TiO2) is a highly valuable material that has numerous industrial applications, making it a promising investment opportunity. By carefully planning and executing each step, a successful and profitable TiO2 manufacturing business can be established, offering great returns and contributing to the growth of the industry. So, if you are considering starting a manufacturing business for titanium dioxide, take the time to do your research, seek expert advice, and be ready to make a substantial investment in this exciting opportunity.

Visit the page Select and Choose the Right Business Startup for You for sorting out the questions arising in your mind before starting any business and know which start-up you can plan.

We, at NPCS, endeavor to make business selection a simple and convenient step for any entrepreneur/startup. Our expert team, by capitalizing on its dexterity and decade's long experience in the field, has created a list of profitable ventures for entrepreneurs who wish to diversify or venture. The list so mentioned is updated regularly to give you a regular dose of new emerging opportunities.

Click here to send your queries/Contact Us

Reasons for Buying NIIR Report:

● Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

● Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

● Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

● Our Report provides indispensable buyers' data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

● Our report provides forecasts of key parameters which help to anticipate the industry performance.

● We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

NPCS has access to and has studied the titanium dioxide market. All titanium dioxide producers, researchers, technocrats, consultants, and new business owners can benefit from the research.

See More Links:

· Start a Business in Asia

· Start a Business in Potential Countries for Doing Business

· Best Industry for Doing Business

· Business Ideas with Low, Medium & High Investment

· Looking for Most Demandable Business Ideas for Startups

· Startup Consulting Services

· Start a Business in Africa

· Start a Business in India

· Start a Business in Middle East

· Related Videos

· Related Books

· Related Projects

· Related Market Research Reports

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬

NIIR PROJECT CONSULTANCY SERVICES, DELHI

An ISO 9001:2015 Company

ENTREPRENEUR INDIA

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: npcs.ei@gmail.com

info@entrepreneurindia.co

Tel: +91-11-23843955, 23845654, 23845886

Mobile: +91-9097075054, 8800733955

Website: https://www.entrepreneurindia.co

https://www.niir.org