Project Report on Ferroalloys: The Industry, Production and Development

Ferro alloys have been developed in order to improve the properties of steel and alloys by introducing specific alloying elements in required quantity in the most practical, technical and cost-effective way. Ferroalloys are alloys of one or more alloying elements with iron, to add chemical elements into molten metal. The production of ferroalloys plays a major role in the manufacturing chain between mining and steel and alloys. The important task of ferroalloys industry is reduction of metals needed from natural minerals. In the industry from the large range available the most common ferroalloys are ferromanganese, silicomanganese, and Ferro chrome and noble Ferro-alloys. These are used in the production of steel and alloys. Alloys impart different qualities to steel and cast iron during the production and hence is closely associated with the iron and steel industry, which are the leading consumers of ferroalloys.

Different Types of Ferroalloys

Ferromanganese Ferromanganese is an iron alloy that is obtained during carbothermal reaction. This alloy is used for the manufacturing of various types of steel. It is a stable and non-harmful material during normal conditions but when in contact with moisture, or acids it produces metal oxides that can be harmful following sustained exposure. Although it’s imperative to take precautions to prevent the spreading of the dust from it as it has pollutant nature and can cause irritation in the airways. The production of ferromanganese in year 2015-2016 was approx. 5, 18,000 tones whereas the consumption for the same year was 79,200 tones. Moreover in upcoming years the consumption increased to 5, 00,238 tones.

Ferrosilicon Ferrosilicon is an alloy composition of iron and silicon with a content ranging from 40% and 80%. Its application includes its use as a deoxidizer in the manufacturing of stainless steel. Ferrosilicon can cause explosion or deflagration if the produced hydrogen comes in contact with moisture. The production of Ferro silicon in year 2015-2016 was 90,000 tones and the domestic consumption in the organized sector was at 30,200 tones; the apparent consumption was approx. 2, 66,303 tones in year 2016-2017.

Ferrochrome This alloy is obtained from the reduction of chromium ore or chromite and includes the usage of more than 90% of total production of mineral. Chromium is an essential element of stainless steel, the main application of this alloy is it favors the hardening of these materials and improves wear resistance. The production of ferrochrome in year 2015-2016 was almost about 9, 44,000 tones and the consumption was projected 15,900 tones however the apparent consumption was 3, 10,679 tones in year 2016-2017

Noble Ferro alloys These Ferro alloys are one of the most important additive inputs required majorly in production of alloy and special steel. These alloys are comparatively expensive and are used in production of steel as deoxidant and alloying agents. Nobel Ferro alloys are used majorly in power plants, furnaces and other equipment of pollution control

Production and Capacity

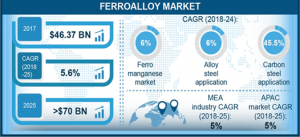

For Ferroalloy market the industries such as construction, automotive and such other sectors are major drivers. The main application of it is in manufacturing different variety of steels. Presence of iron ore in abundance across the globe along with the higher demand for different types of steel grades due to lack of available substitutes will give an up thrust to ferroalloy market in upcoming future. The production of Global crude steel was about 1.6 billion tons in 2017, and showed an increased rate of around 5.3% in comparison to last year. Among all the Ferroalloys the Ferromanganese shows a rising annual growth of approx. 6% over the upcoming years.

Conclusion

For other important details of the industry, NPCS provides the detailed project reports that covers all the major components from business, marketing, forecasted growth. The clients of NPCS, who are from India or NRIs that includes engineers, project consultant and industrial consultant have taken help of these project reports to do their analysis.

Noo_Art20

We can provide you detailed project reports on the following topics. Please select the projects of your interests.

Each detailed project reports cover all the aspects of business, from analysing the market, confirming availability of various necessities such as plant & machinery, raw materials to forecasting the financial requirements. The scope of the report includes assessing market potential, negotiating with collaborators, investment decision making, corporate diversification planning etc. in a very planned manner by formulating detailed manufacturing techniques and forecasting financial aspects by estimating the ost of raw material, formulating the cash flow statement, projecting the balance sheet etc.

We also offer self-contained Pre-Investment and Pre-Feasibility Studies, Market Surveys and Studies, Preparation of Techno-Economic Feasibility Reports, Identification and Selection of Plant and Machinery, Manufacturing Process and or Equipment required, General Guidance, Technical and Commercial Counseling for setting up new industrial projects on the following topics. Many of the engineers, project consultant & industrial consultancy firms in India and worldwide use our project reports as one of the input in doing their analysis.