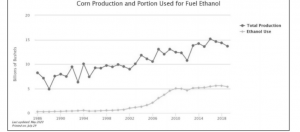

Ethanol is an alternative fuel that is manufactured in the United States and is most often derived from maize. It may also be produced from cellulosic feedstock, such as agricultural wastes and wood, but this is not as popular as it used to be. In addition to receiving maize by train or using alternative feedstock, plants outside the Midwest are usually situated near densely populated urban areas.

Start a Business in Ethanol Industry, Click Here

Production

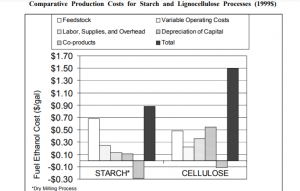

The manner by which ethanol is produced is determined by the kind of feedstock utilized. Cellulosic feedstock takes longer to convert than starch- or sugar-based feedstock, thus the procedure is faster with these feedstocks.

● Production of Ethanol from Starch and Sugar Sources

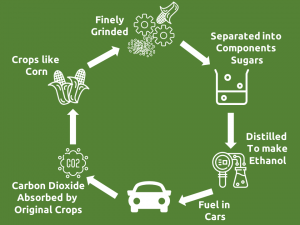

The vast majority of ethanol generated in the United States is derived from starch-based crops and processed either in a dry or wet mill. Due to reduced initial expenditures, dry mill ethanol facilities account for almost 90 percent of all ethanol plants. When maize is ground into flour and fermented to produce ethanol, it is combined with co-products such as distillers grains and carbon dioxide to create a dry-milling process.

Related Project:- Dual Feed Distillery (Ethanol as Bio-Fuel)

Wet-mill facilities are mainly responsible for the production of maize sweeteners, as well as ethanol and a variety of other byproducts (such as corn oil and starch). Using wet mills, maize is separated into its constituent parts: starch, protein, and fiber. These components are then processed into products such as ethanol.

Best Industry for Doing Business, Click Here

● Production of Cellulosic Materials

A more complex procedure than utilizing starch-based crops is required for producing ethanol from cellulosic feedstock, which include grass, wood, and agricultural leftovers. The production of cellulosic ethanol may be accomplished via two main pathways- biochemical and thermochemical. It is necessary to perform a pretreatment in order to liberate hemicellulose sugars, which is then followed by hydrolysis in order to break down the cellulose into sugars.

Ethanol is produced via the fermentation of sugars, and lignin is recovered and converted into energy to fuel the fermentation process. Syngas is produced via the thermochemical conversion process, which includes adding heat and chemicals to a biomass feedstock in order to generate carbon monoxide and hydrogen gas. In this process, syngas is combined with a catalyst and transformed into ethanol as well as other liquid byproducts.

Related Book:- Handbook On Chemical Industries (Alcohol Based)

Related Video- Lucrative Business of Dual Feed Distillery (Ethanol as Bio-Fuel)

Why Invest in Corn to Ethanol Production?

● As part of its efforts to reach a 20 percent ethanol blending goal for gasoline supplied in the nation by 2025, India has set a target to increase its ethanol production by 80 percent with new investments totaling Rs 41,000 crore.

● Already, 422 investment applications have been accepted, and more are in the process. There is little possibility in sugarcane-based ethanol facilities, while there is tremendous potential in grain-based ethanol plants.

● Prime Minister Narendra Modi has announced a five-year delay in India's 0 percent ethanol mix goal, which will now be achieved in 2025. A total of 819 crore liters of ethanol are generated in the nation per year at the moment.

Start a Business in India, Click Here

Related Videos:- Chemicals (Organic, Inorganic, Industrial)

The government has enabled the ethanol sector to obtain rice from the official stock held by the Food Corporation of India (FCI) at a rate of Rs 20/kg and the measure is intended to ensure that the units do not suffer a short-term raw material shortfall. Because it is economically feasible, maize is the grain of choice for ethanol production throughout the world.

● The use of E20 fuel (20 percent ethanol with 80 percent gasoline) is anticipated to decrease carbon monoxide emissions by 30 to 50 percent. 3.5 MT of sugar is expected to be diverted to ethanol in the upcoming sugar season 2021-22 (October-September), and that by 2025, approximately 6 MT of sugar is targeted to be diverted to ethanol, which would solve the problem of excess sugarcane/sugar while also assisting sugar mills in clearing cane price dues from farmers.

COVID-19 measures combined with stay-at-home directives have reduced fuel usage to the point that ethanol production and consumption have almost completely stopped. Ethanol facilities reported slowdowns and decreased capacity in April, with sixty-two (62) units reporting full shutdowns. Corn prices fall as a result of a decrease in ethanol demand. Many people are concerned about how the ethanol business will return to normal as a result of the uncertainty surrounding ethanol consumption.

Start a Business in Middle East, Click Here

Niir Project Consultancy Services (NPCS) had prepared project report on Ethanol Production - Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost and Revenue, Plant Economics. The project report provided by NPCS gives a detailed market review. The report analyses the market confirms the availability of various necessities such as plant & machinery, raw materials and tells about the forecasting financial requirements. A lot of professionals have taken benefit from the project reports if you are interested in the manufacturing business of Ethanol Production or any other business get in contact with us from the official website of NPCS.

Start a Business in Africa, Click Here

Start a Business in Asia, Click Here

Start a Business in Potential Countries for Doing Business, Click Here

Business Ideas with Low, Medium & High Investment, Click Here

Looking for Most Demandable Business Ideas for Startups, Click Here

Pall_20Art21

#NPCS #ethanol #ethanolproduction #Ethanolbusiness #ethanolindustry #ethanolmarket #ethylalcohol #EntrepreneurIndia